KS4007 KS4008 Keyestudio Complete Starter for BBC Micro:bit

1. Description:

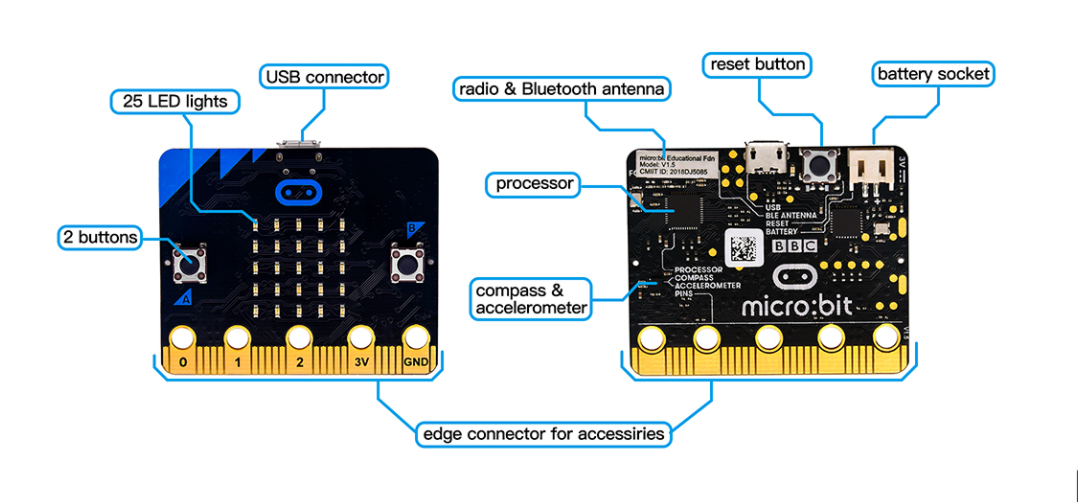

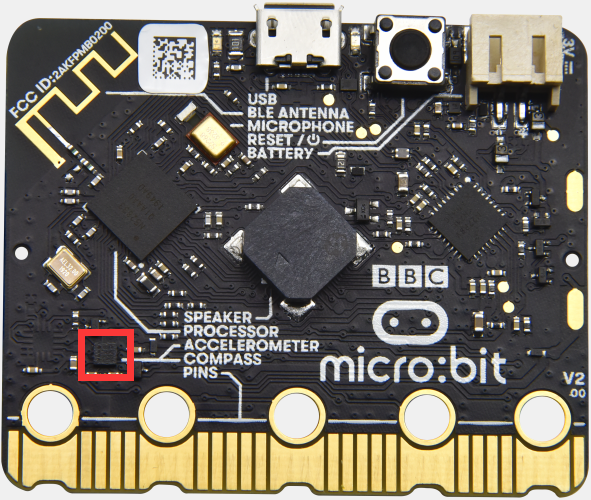

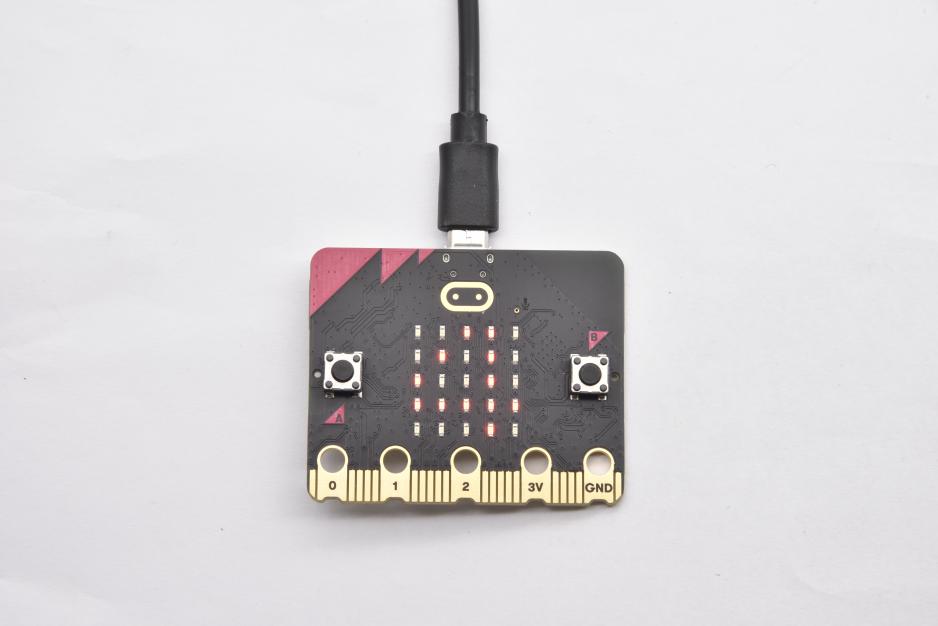

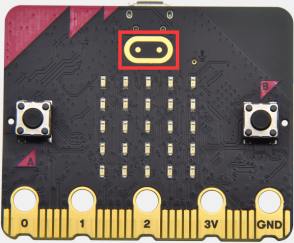

Micro:bit, half the size of a credit card, is a micro controller with ARM structure designed by BBC. It is mainly applied to programming education of teenagers, coming with an on-board Bluetooth, an accelerator, 3 buttons, an electronic compass and a 5 x 5 LED dot matrix.

To make starters grasp how to program by micro:bit boards, we launch this kit for them. Moreover, this kit consists of the commonly used resistors, LEDs, digital tubes, sensors and modules. A numerous of experimental courses are provided to guide you as well. We believe that you will enjoy playing with this micro:bit kit.

2. Kit List:

When we get the keyestudio Micro:bit premium learning kit, please check whether the listed components are all included.

(Note:kit KS4007 isn’t inclusive of a micro:bit board while kit KS4008 contains one)

# |

Name |

QTY |

Picture |

|---|---|---|---|

0 |

Micro:bit Main Board V2.0 |

0 for KS4007 |

|

1 |

Micro:bit T Type Shield |

1 |

|

2 |

Red LED |

10 |

|

3 |

Yellow LED |

10 |

|

4 |

Green LED |

10 |

|

5 |

RGB |

1 |

|

6 |

Adjustable Potentiometer |

1 |

|

7 |

Photoresistor |

3 |

|

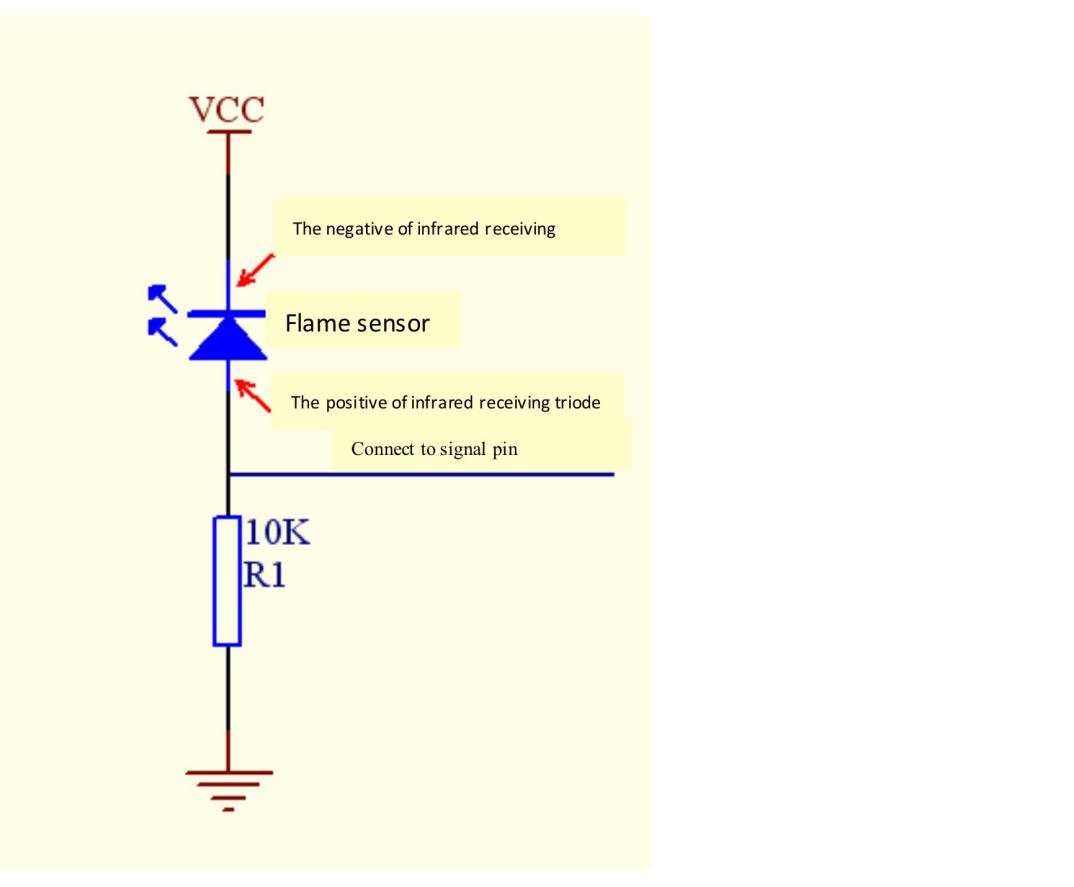

8 |

Flame Sensor |

1 |

|

9 |

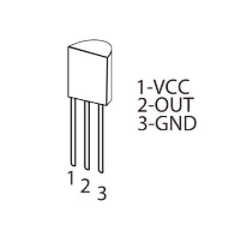

LM35DZ Temperature Sensor |

1 |

|

10 |

S8050 Triode |

1 |

|

11 |

Tilt Switch |

2 |

|

12 |

220Ω Resistor |

10 |

|

13 |

1KΩ Resistor |

10 |

|

14 |

10 KΩ Resistor |

10 |

|

15 |

2.4KΩ Resistor |

8 |

|

16 |

51Ω Resistor |

5 |

|

17 |

Active Buzzer |

1 |

|

18 |

Passive Buzzer |

1 |

|

19 |

Button Module |

4 |

|

20 |

1-Digit Tube Module |

1 |

|

21 |

4-Digit Tube Module |

1 |

|

22 |

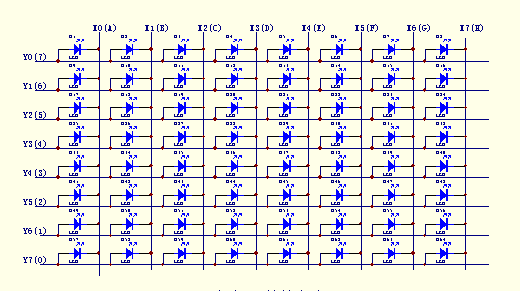

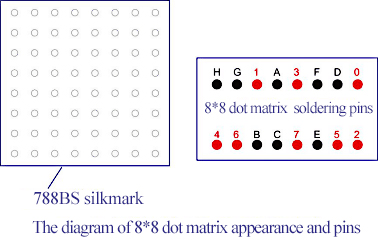

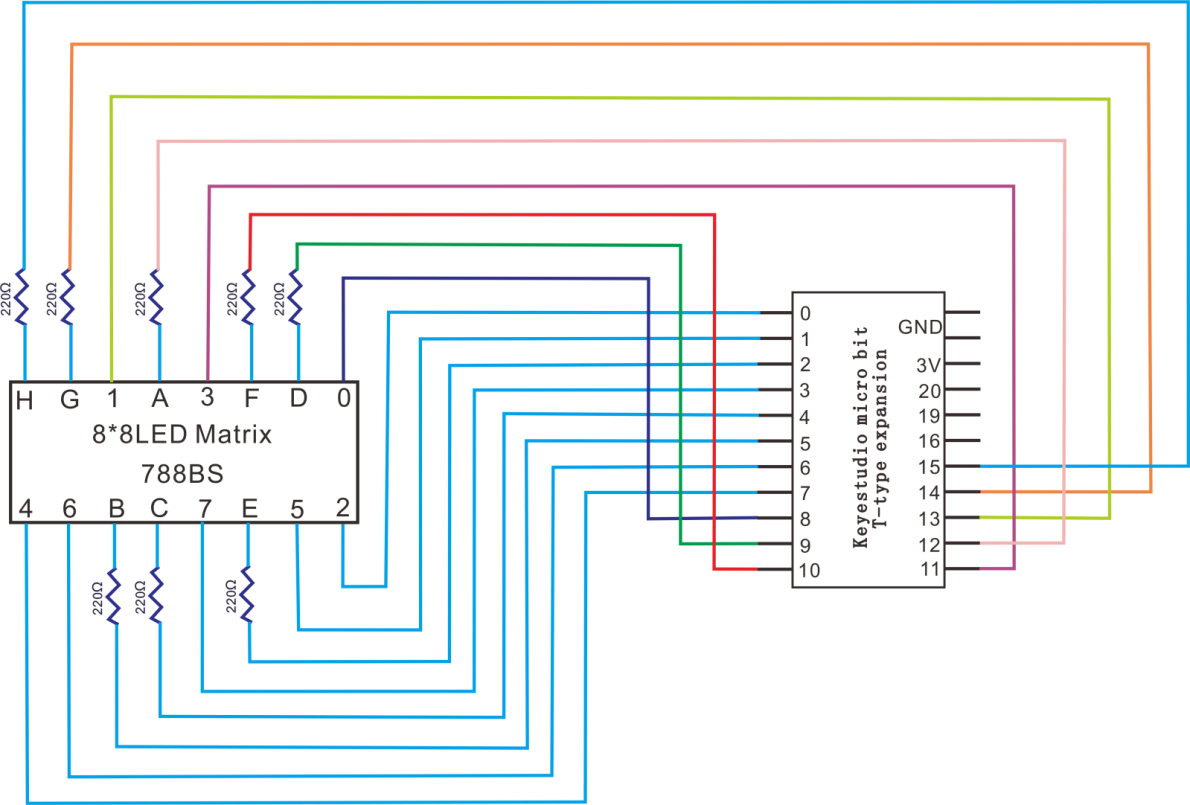

8*8 Dot matrix |

1 |

|

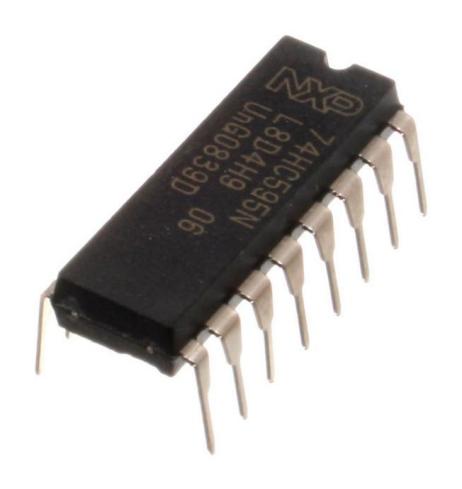

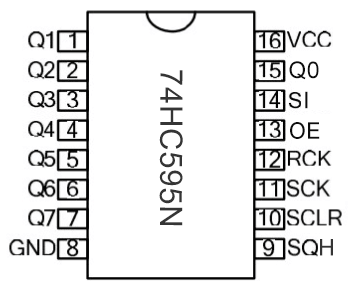

23 |

74HC595N Chip |

1 |

|

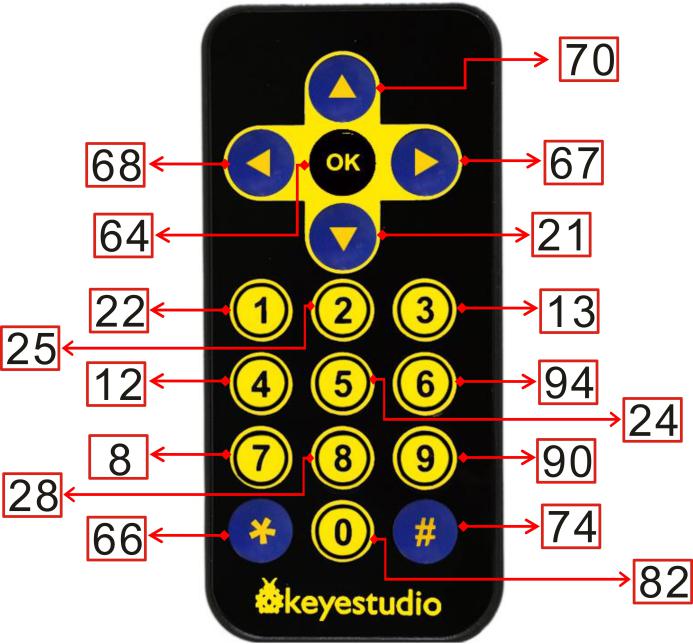

24 |

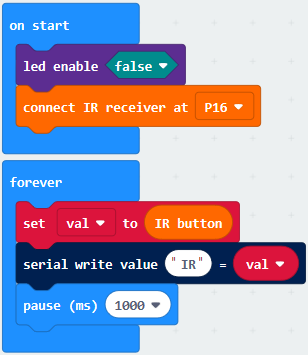

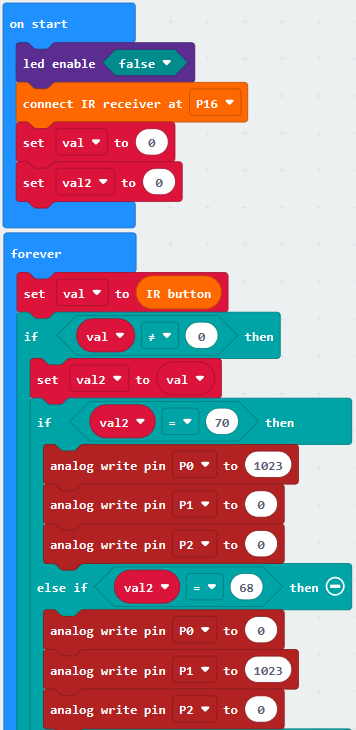

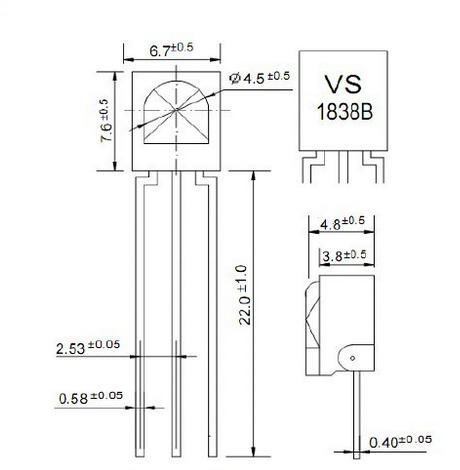

IR Receiver |

1 |

|

25 |

IR Remote Control |

1 |

|

26 |

L293D Motor Driver Chip |

1 |

|

27 |

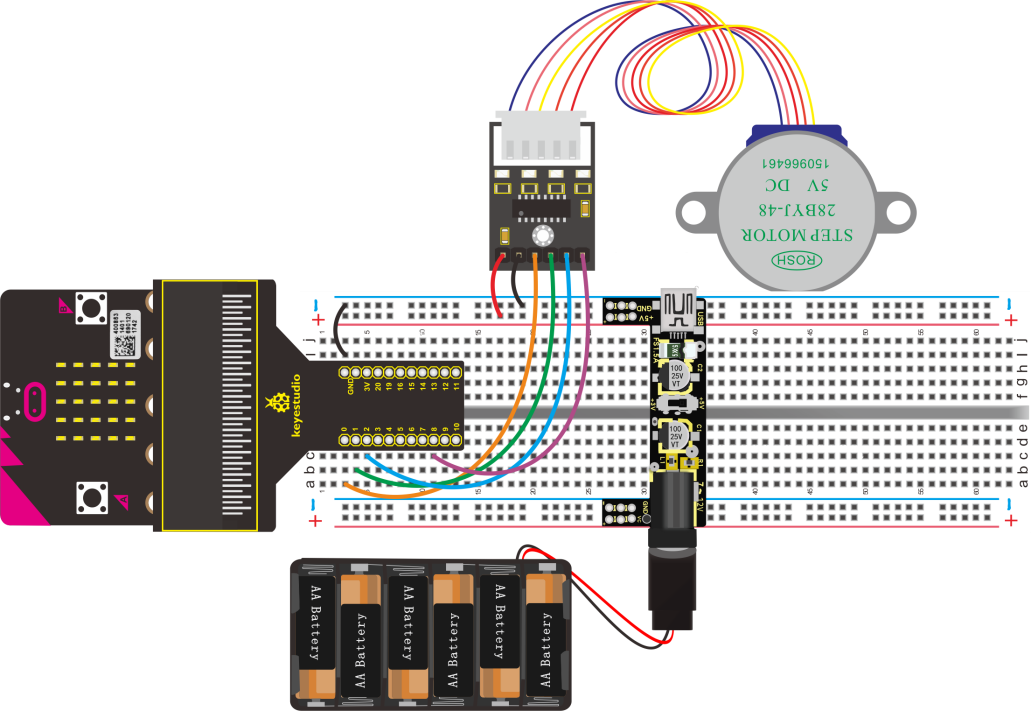

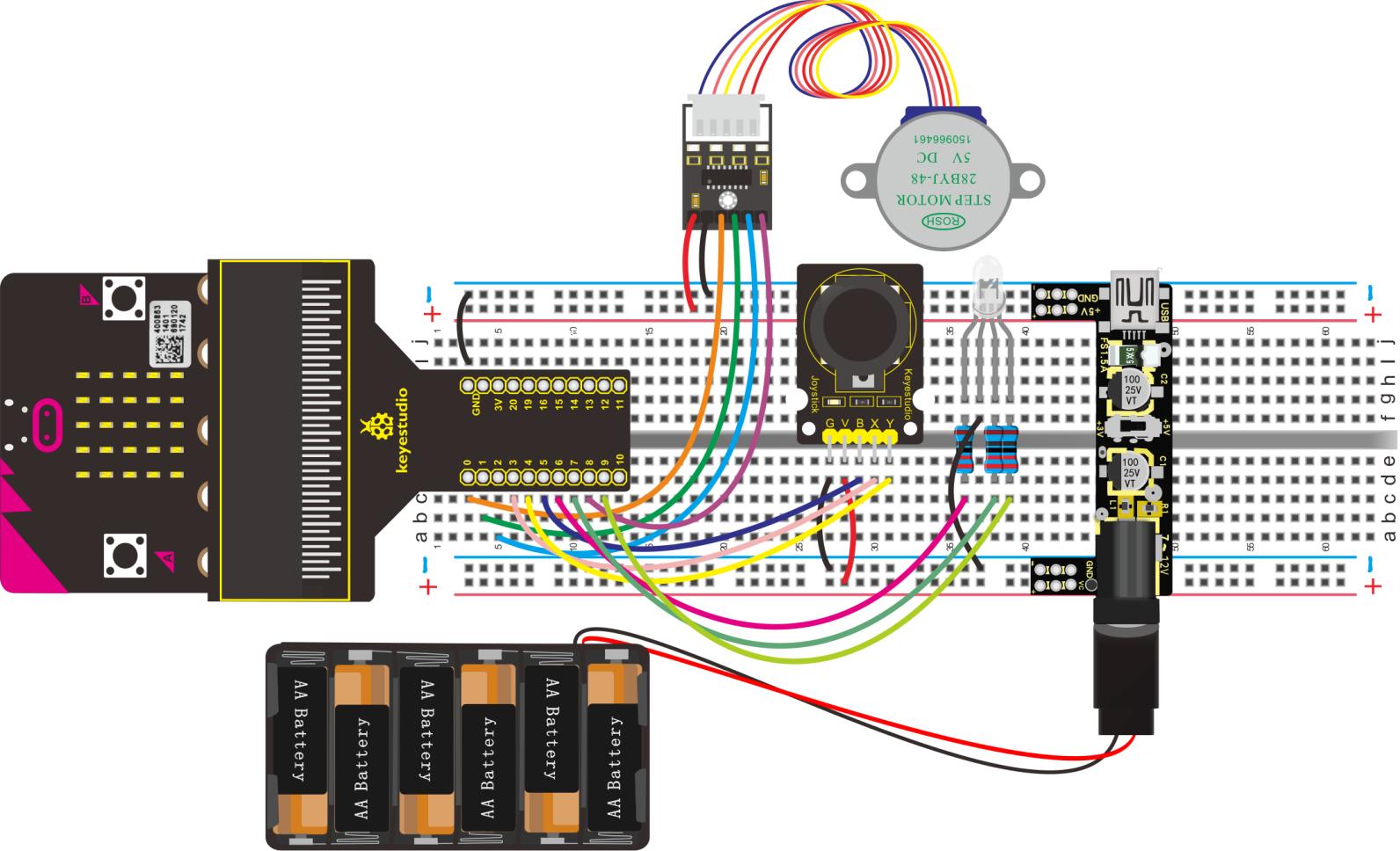

ULN2003 Stepper Motor Drive Module |

1 |

|

28 |

Water Level Sensor |

1 |

|

29 |

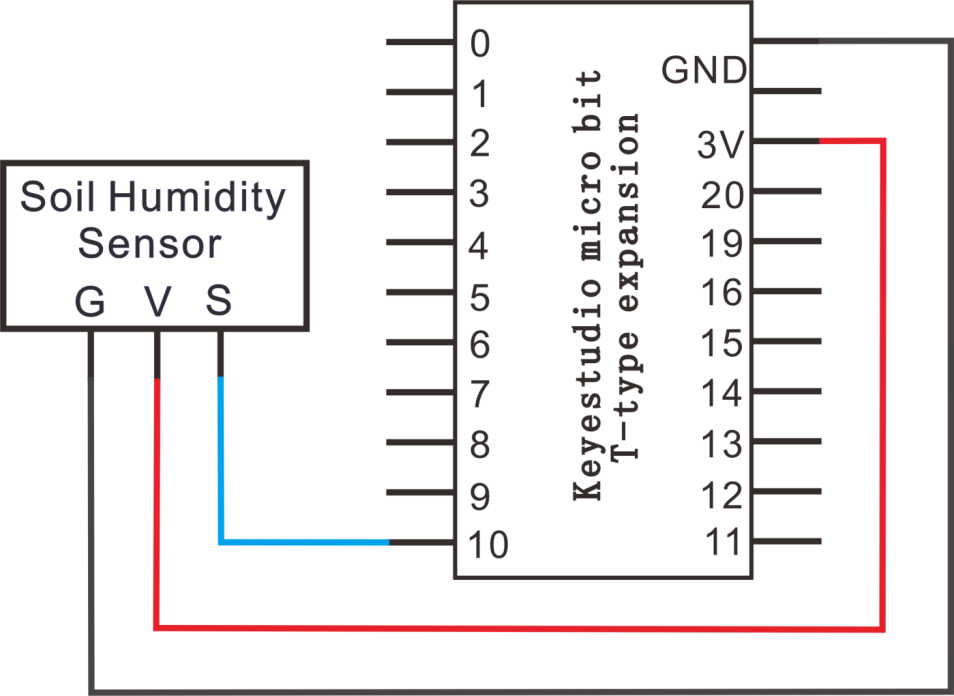

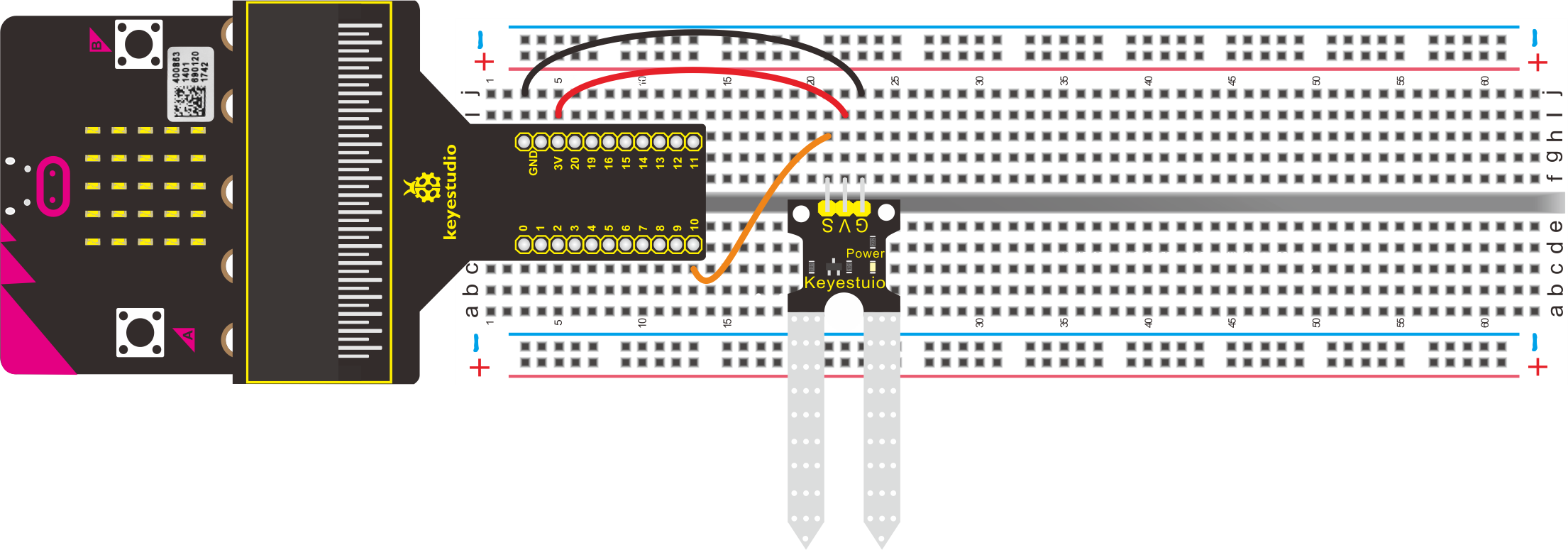

Soil Humidity Sensor |

1 |

|

30 |

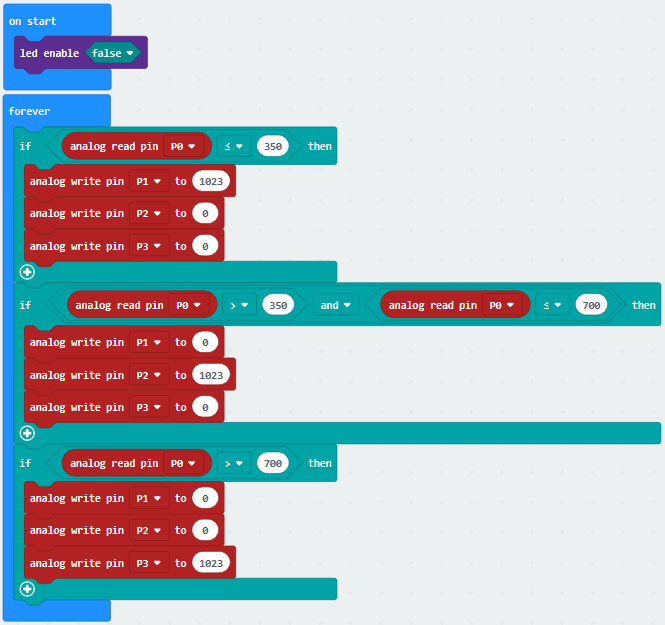

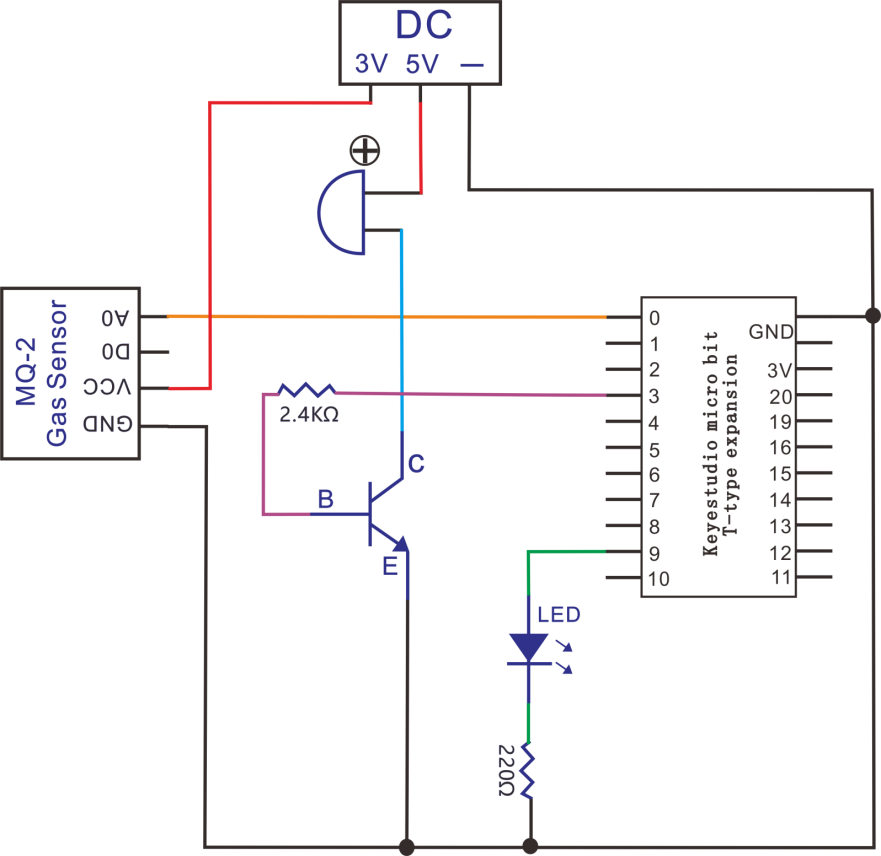

MQ-2 Gas Sensor |

1 |

|

31 |

5-wire Stepper Motor |

1 |

|

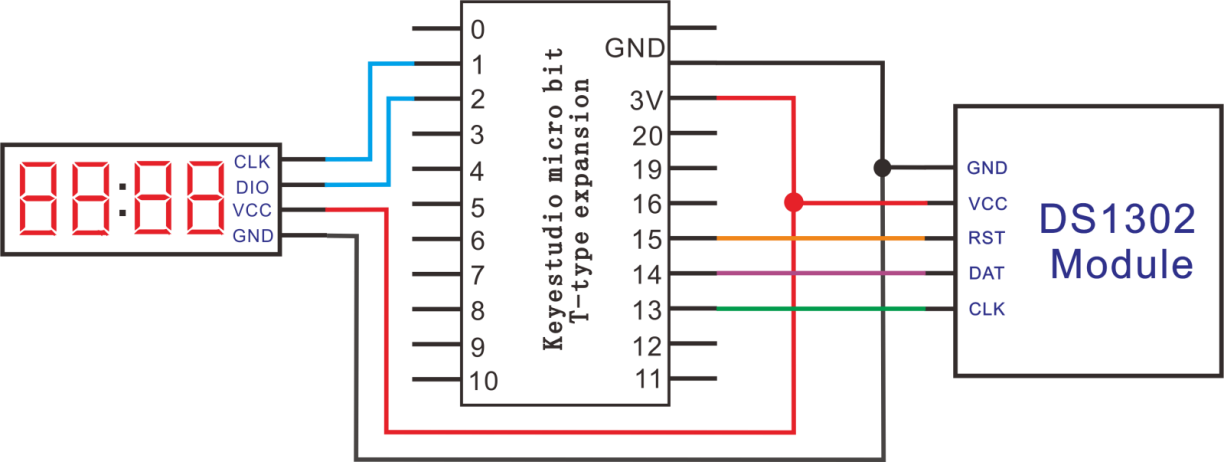

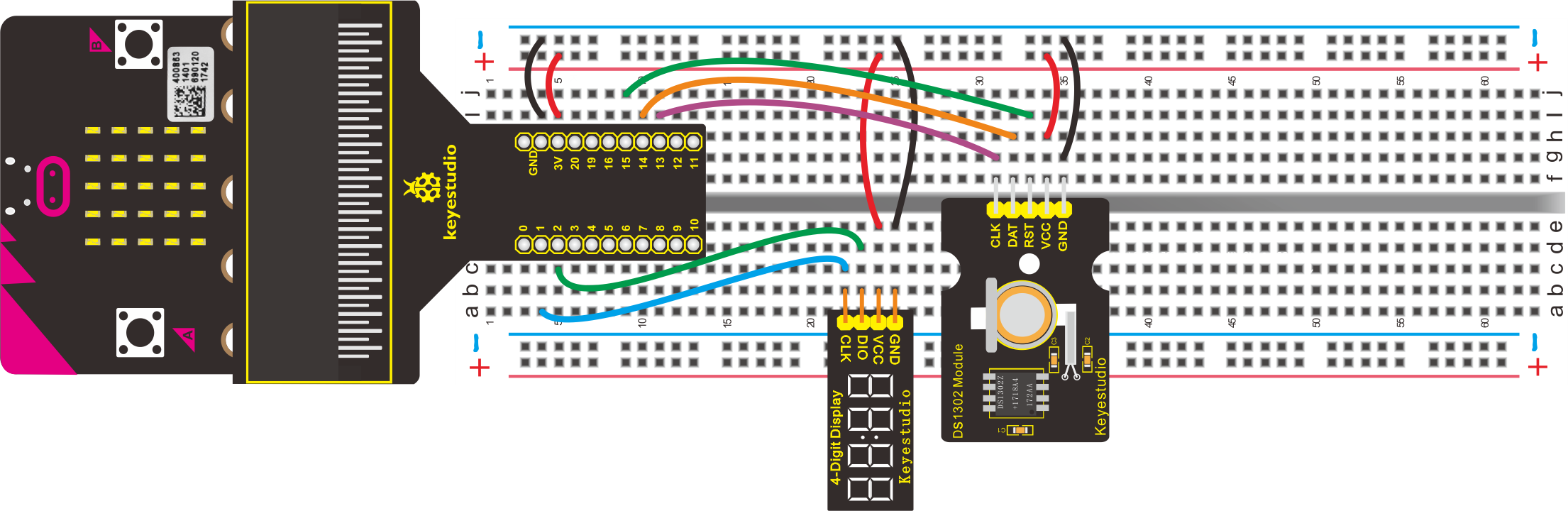

32 |

DS1302 Clock Module |

1 |

|

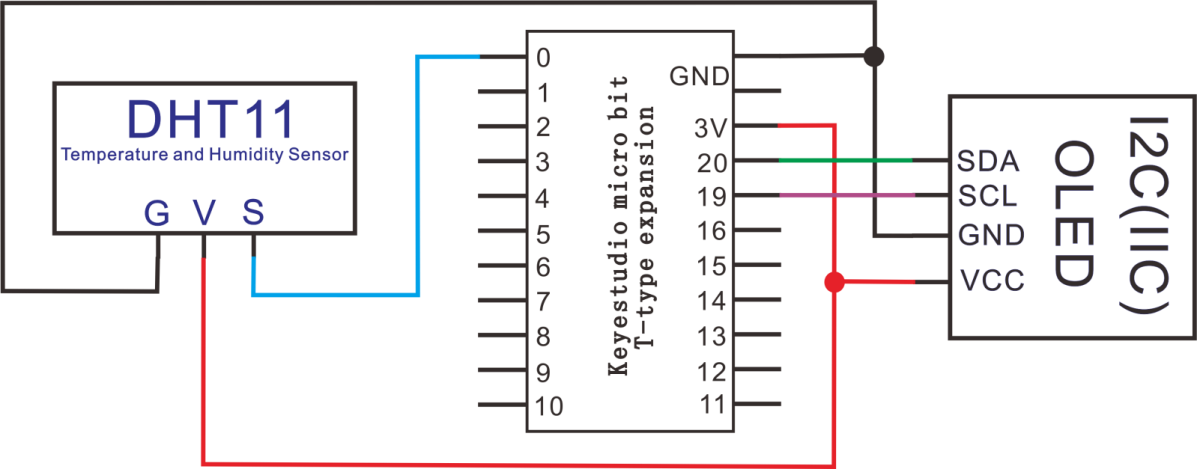

33 |

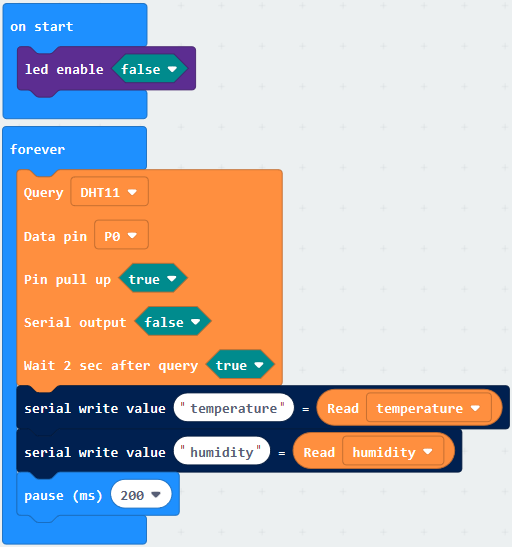

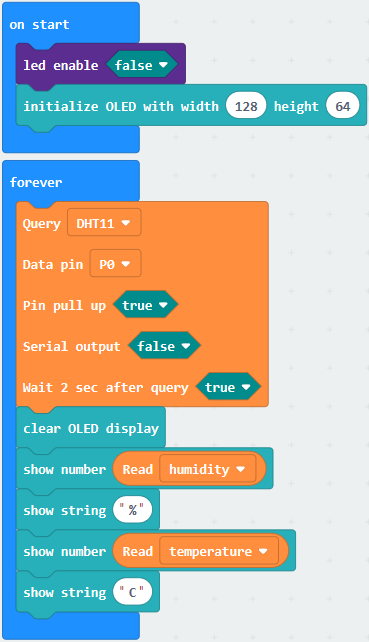

DHT11 Temperature |

1 |

|

34 |

PIR Motion Sensor |

1 |

|

35 |

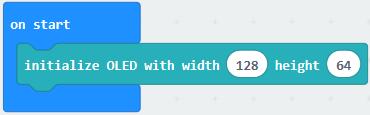

OLED Display Module |

1 |

|

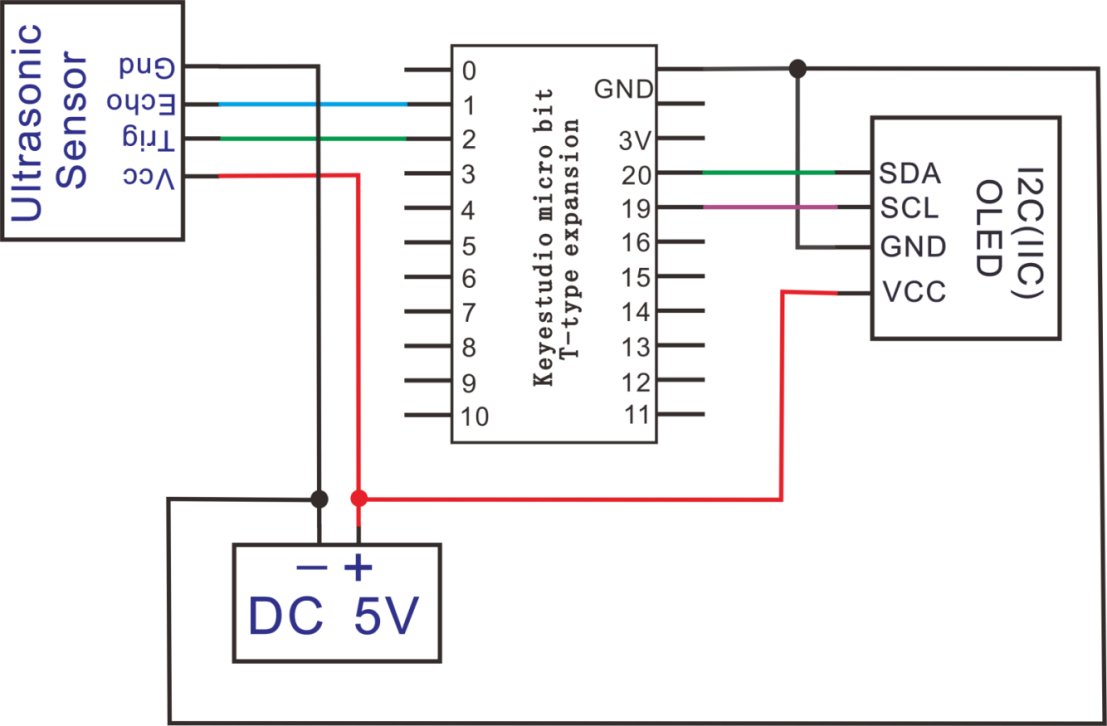

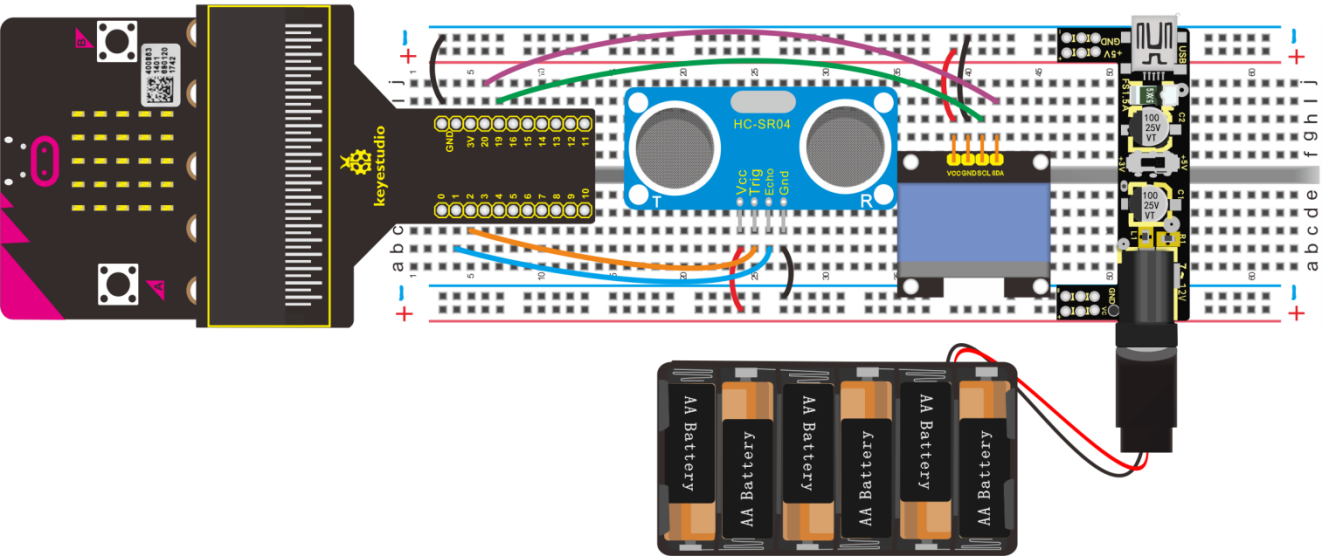

36 |

HC-SR04 Ultrasonic Sensor |

1 |

|

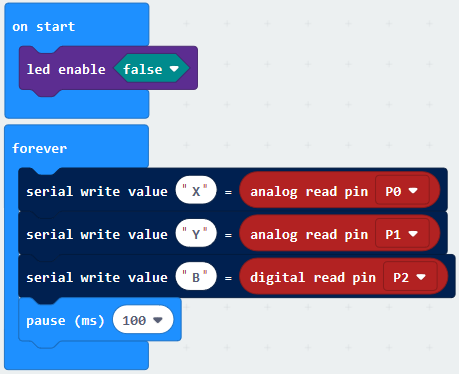

37 |

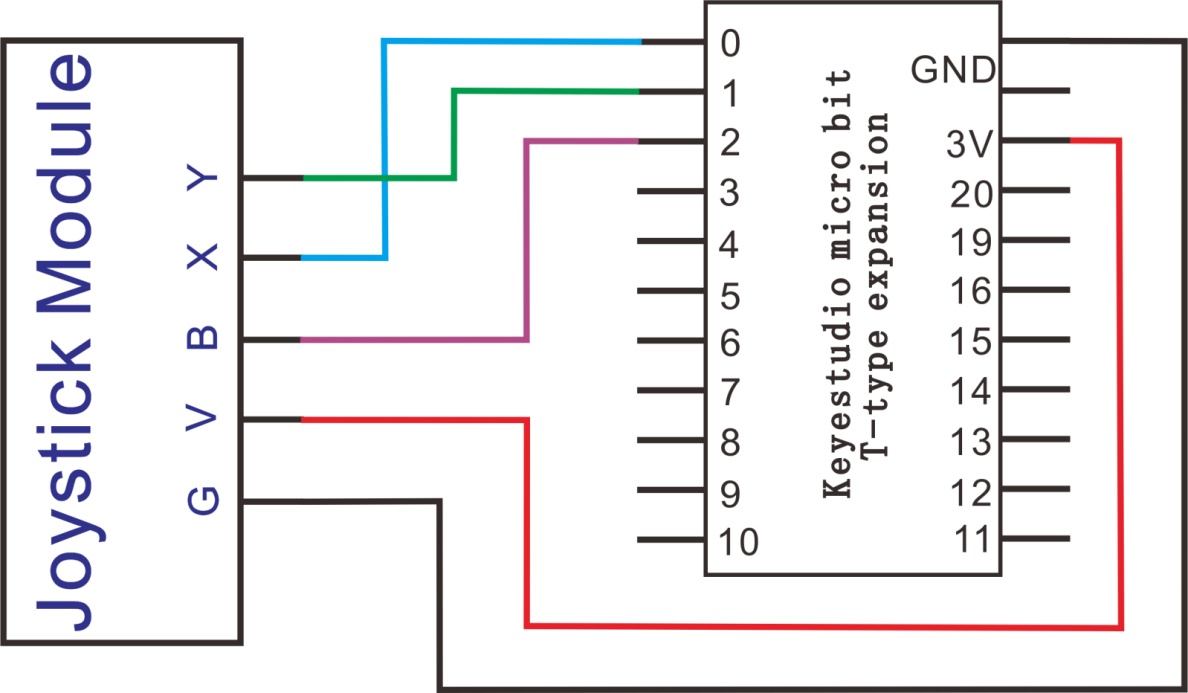

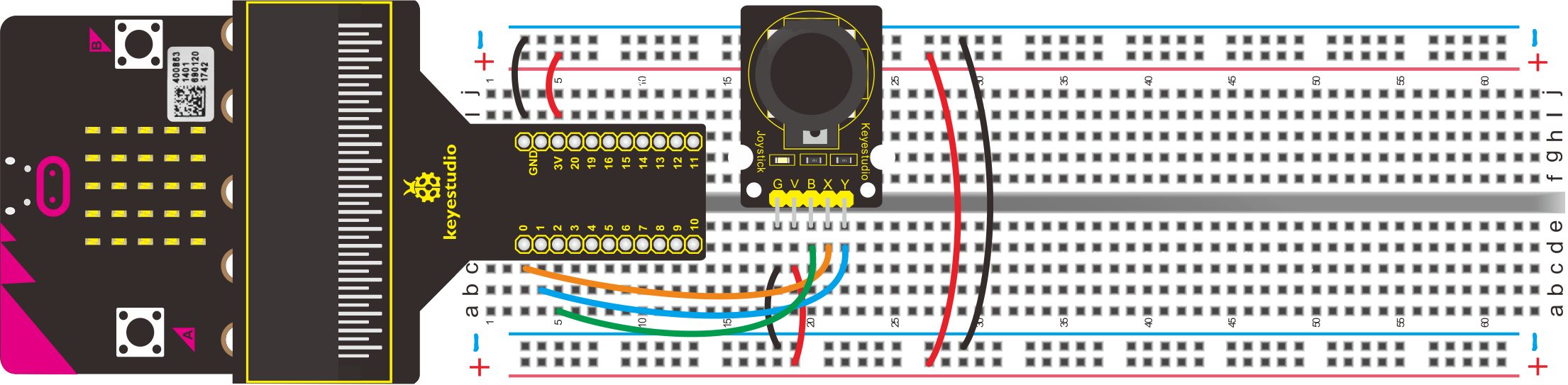

Joystick Module |

1 |

|

38 |

Micro Servo |

1 |

|

39 |

1-channel Relay Module |

1 |

|

40 |

Sound Sensor |

1 |

|

41 |

Specialized Power Module for Breadboard |

1 |

|

42 |

DC Motor |

1 |

|

43 |

6 AA Battery holder |

1 |

|

44 |

Breadboard |

1 |

|

45 |

Breadboard Wire |

30 |

|

46 |

40pins M-F DuPont Line |

1 |

|

47 |

DC 5V Water Pump |

1 |

|

48 |

Resistor Color Chart |

1 |

|

49 |

Fan |

1 |

|

50 |

Plastic Water Pipe |

1 |

|

51 |

2 AA Battery Holder |

1 |

|

52 |

1.5V AA Battery |

8 |

|

53 |

USB cable |

1 |

|

3.Introduction

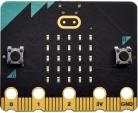

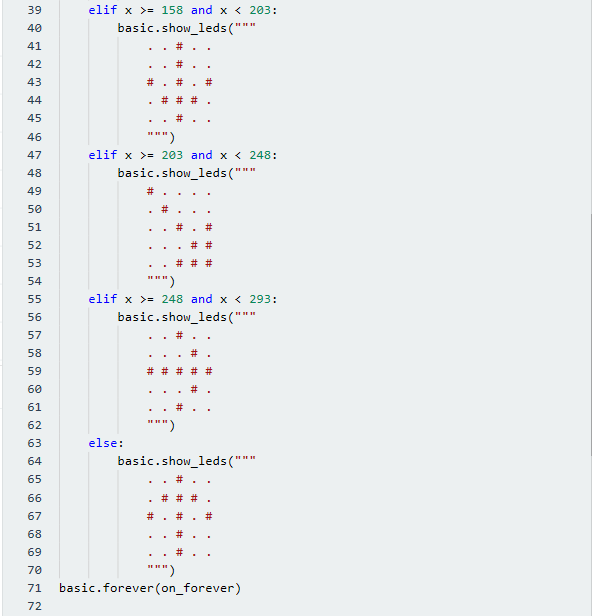

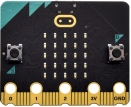

( 1 )What is Micro:bit?

Designed by BBC, Micro:bit main board aims to help children aged above 10 years old to have a better learning of programming.

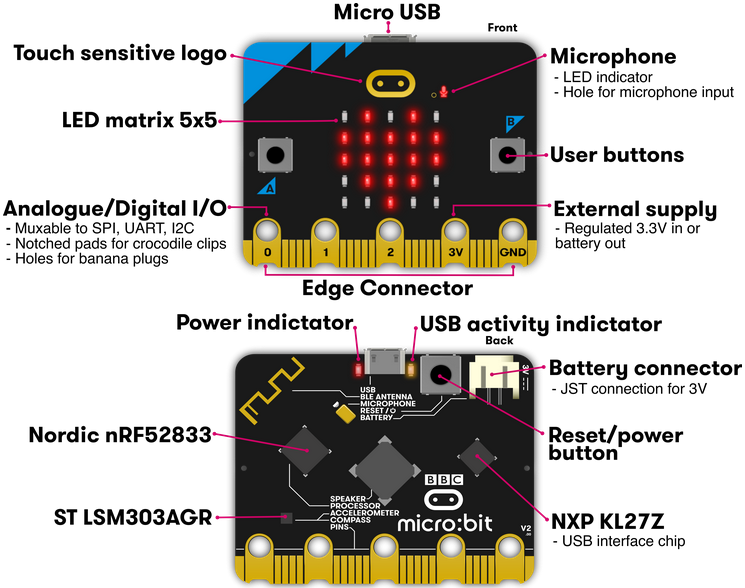

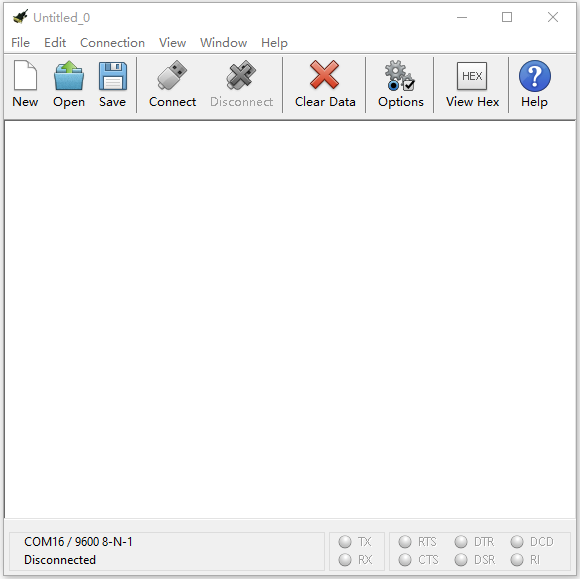

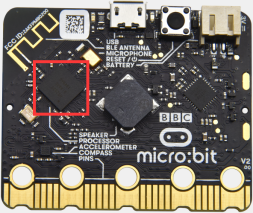

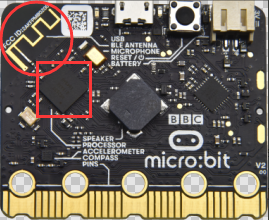

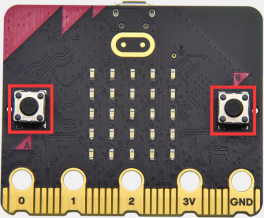

It is equipped with loads of components,including a 5*5 LED dot matrix, 2 programmable buttons, an electronic compass, a Micro USB interface and a Bluetooth module and others. Though it is just the size of a credit card, it boasts multiple functions. To name just a few, it can be applied in programming video games, making interactions between light and sound, controlling a robot, conducting scientific experiments, developing wearable devices and make some cool inventions like robots and musical instruments, basically everything imaginable.

This new version, that’s version 2.0, of Micro:bit main board has a touch-sensitive logo and a MEMS microphone. And there is a buzzer built in the other side of the board which makes playing all kinds of sound possible without any external equipment. The golden fingers and gears added provide a better fixing of crocodile clips. Moreover, this board has a sleeping mode to lower the power consumption of battery and it can be entered if users long press the Reset & Power button on the back of it. More importantly, the CPU capacity of this version is much better than that of the V1.5 and the V2 has more RMA.

In final analysis, the V2 Micro:bit main board can allow customers to explore more functions so as to make more innovative products.

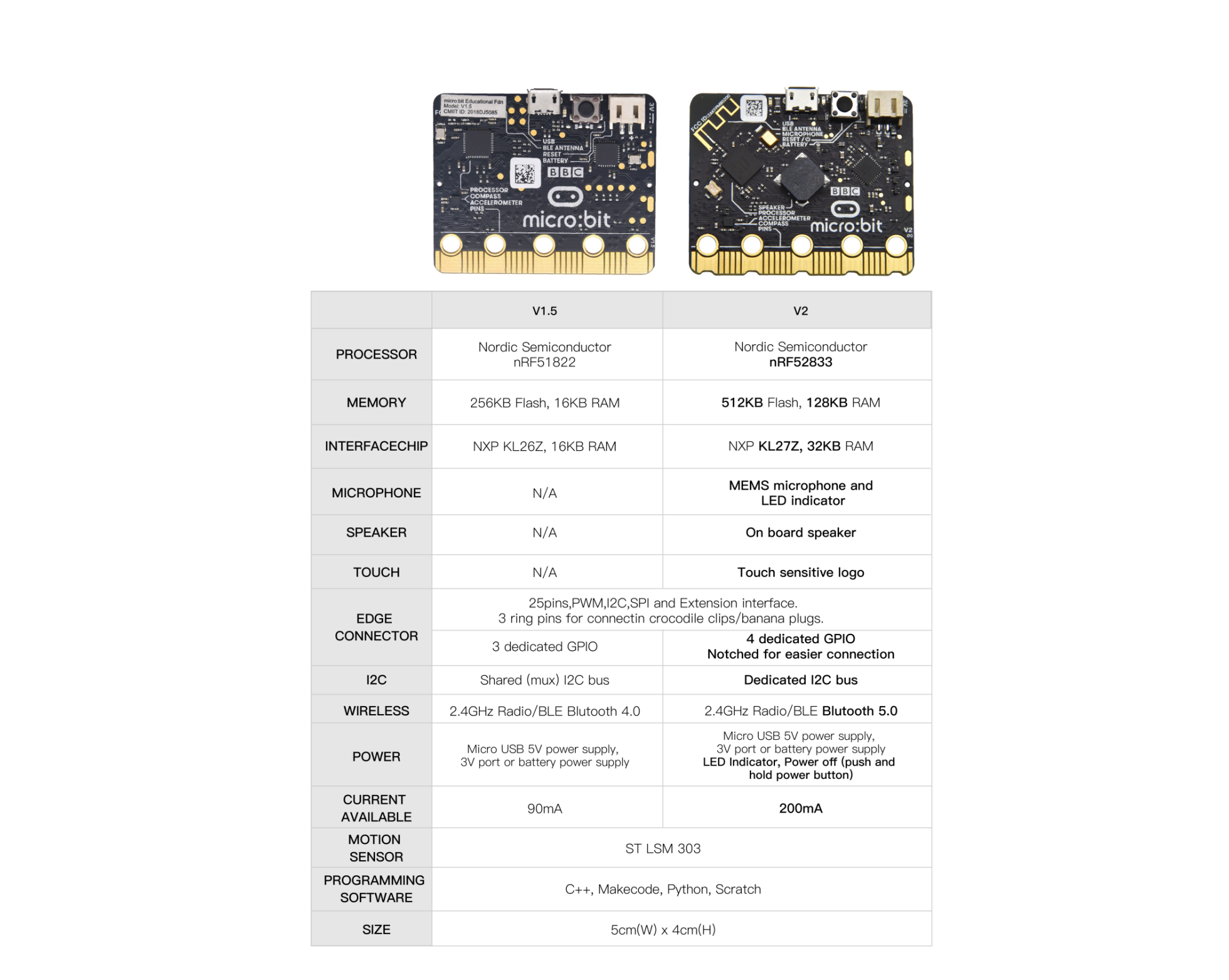

( 2 ) Comparison between V2.0 & V1.5

Micro:bit main board V2.0

Micro:bit main board V1.5

More details:

For the Micro: Bit main board V2, pressing the Reset & Power button , it will reset the Micro: Bit and rerun the program.If you hold it tight, the red LED will slowly get darker.When the power indicator flickers to darkness, releasing the button and your Micro: Bit board will enter sleep mode for power saving. This will make your battery more durable. And you could press this button again to ‘wake up’ your Micro:bit.

For more information,please resort to following links:

https://tech.microbit.org/hardware/

https://microbit.org/new-microbit/

https://www.microbit.org/get-started/user-guide/overview/

https://microbit.org/get-started/user-guide/features-in-depth/

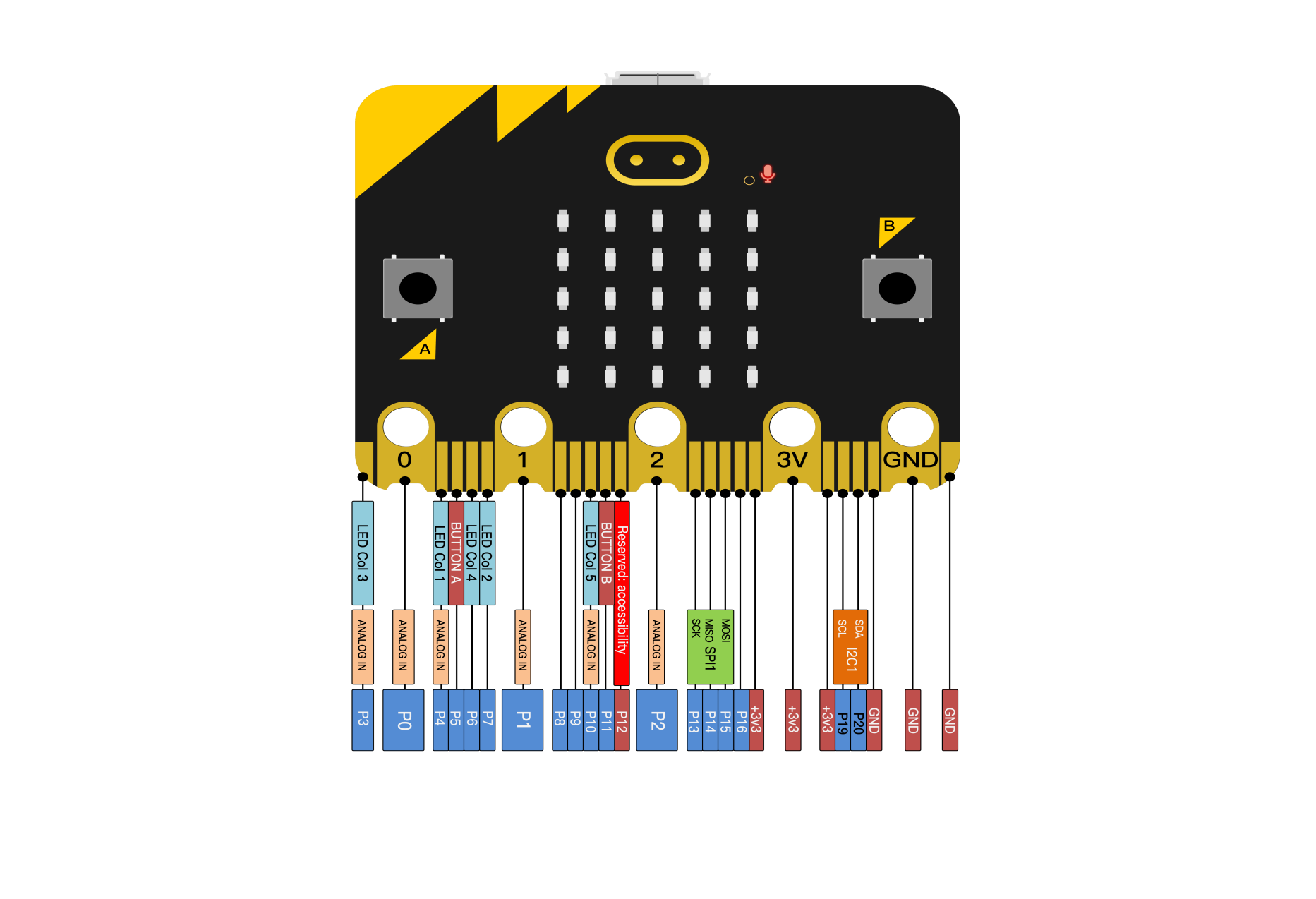

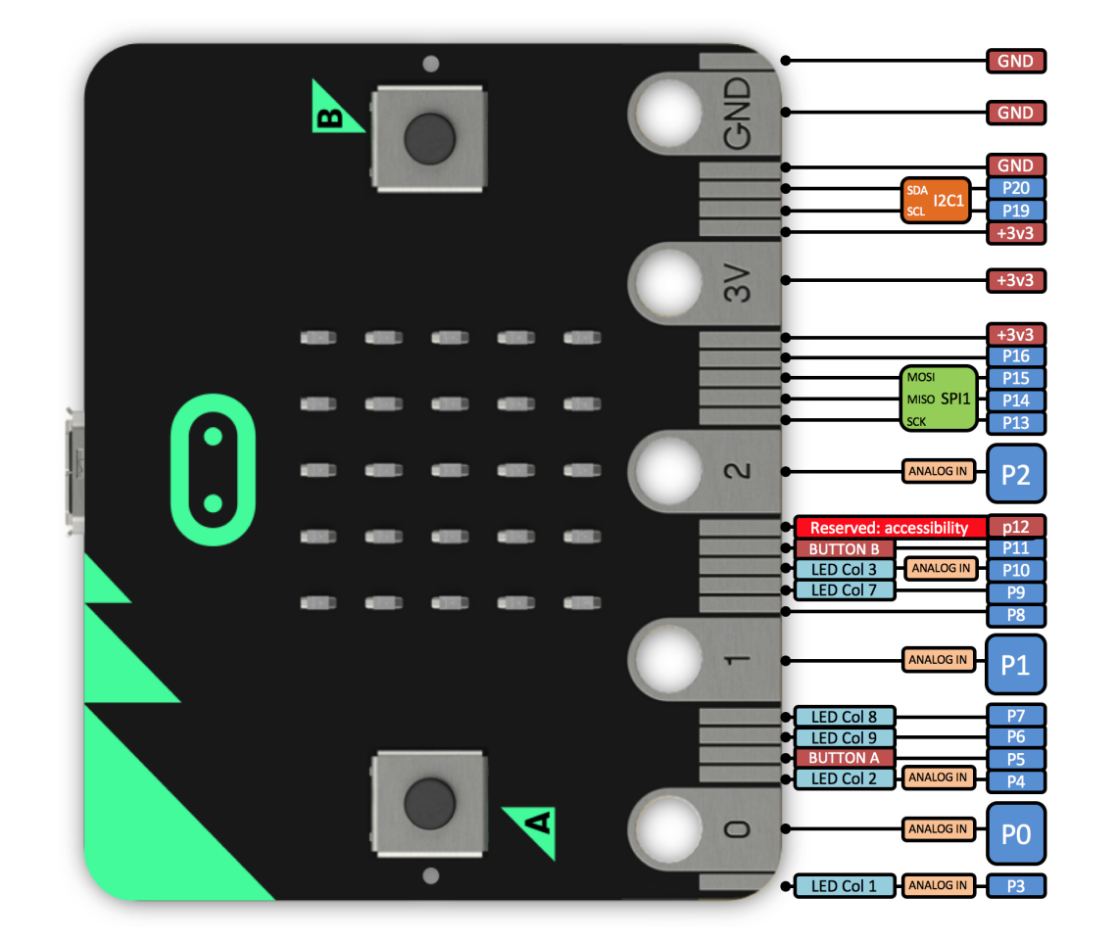

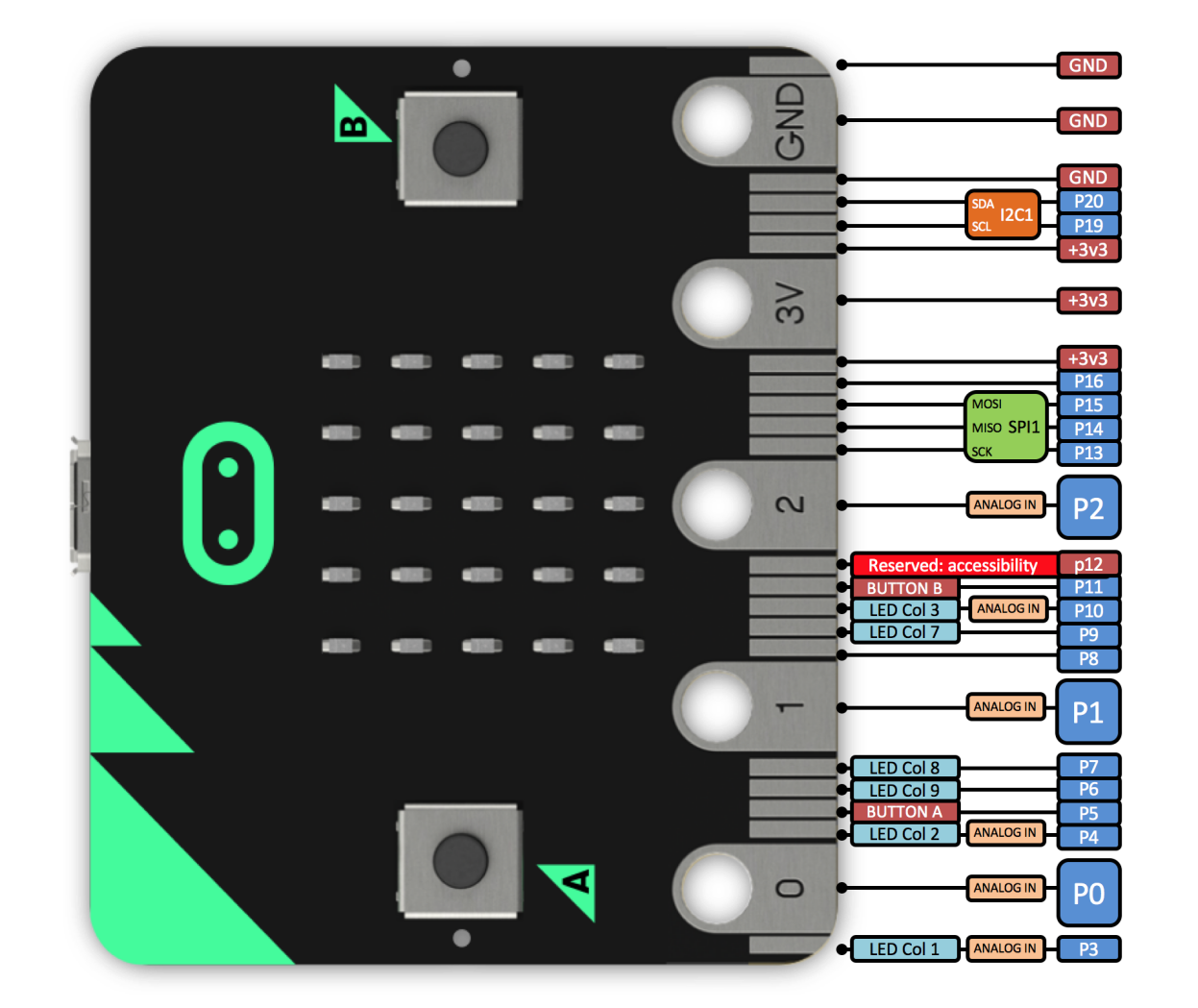

( 3 ) Pinout

Micro:bit main board V2.0 VS V1.5

Browse the official website for more details:

https://tech.microbit.org/hardware/edgeconnector/

https://microbit.org/guide/hardware/pins/

( 4 )Notes for the application of Micro:bit main board V2.0

it is recommended to cover it with a silicone protector to prevent short circuit for it has a lot of sophisticated electronic components.

its IO port is very weak in driving since it can merely handle current less than 300mA. Therefore, do not connect it with devices operating in large current,such as servo MG995 and DC motor or it will get burnt. Furthermore, you must figure out the current requirements of the devices before you use them and it is generally recommended to use the board together with a Micro:bit shield.

It is recommended to power the main board via the USB interface or via the battery of 3V. The IO port of this board is 3V, so it does not support sensors of 5V. If you need to connect sensors of 5 V, a Micro: Bit expansion board is required.

When using pins(P3、P4、P6、P7、P10)shared with the LED dot matrix, blocking them from the matrix or the LEDs may display randomly and the data about sensors maybe wrong.

The battery port of 3V cannot be connected with battery more than 3.3V or the main board will be damaged.

Forbid to use it on metal products to avoid short circuit.

To put it simple, Micro:bit V2 main board is like a micro computer which has made programming at our fingertips and enhanced digital innovation. And about programming environment, BBC provides a website: https://microbit.org/code/, which has a graphical MakeCode program easy for use.

4.Install Micro:bit driver

If you have downloaded micro:bit driver, then no need to download it again. If it is you first time to use micro:bit main board, then you will have to download the driver.

First of all, connect the micro:bit to your computer using a USB cable.

And enter website https://www.dropbox.com/sh/w5mv8mvvufti0uj/AADTFPTV8NBN0IxQj_3TZ8ETa?dl=0 todownload the driver file of micro:bit .

.

5.Instructions

The following instructions are applied for Windows system but can also serve as a reference if you are using a different system.

5.1 Write code and program

This chapter describes how to write program with the App Micro: Bit and load the program to the Micro: Bit main board V2.

You are recommended to browse the official website of Micro:bit for more details, and the link is attached below:

https://microbit.org/guide/quick/

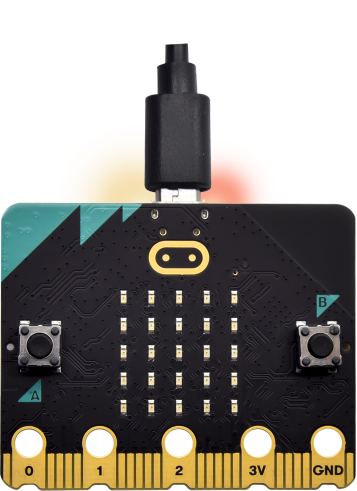

Step 1: connect the Micro: Bit main board V2 with your computer

Firstly, link the Micro: Bit main board V2 with your computer via the USB cable.Macs, PCs, Chromebooks and Linux (including Raspberry Pi)systems are all compatible with the Micro: Bit main board V2.

Note that if you are about to pair the board with your phone or tablet, please refer to this link: https://microbit.org/get-started/user-guide/mobile/

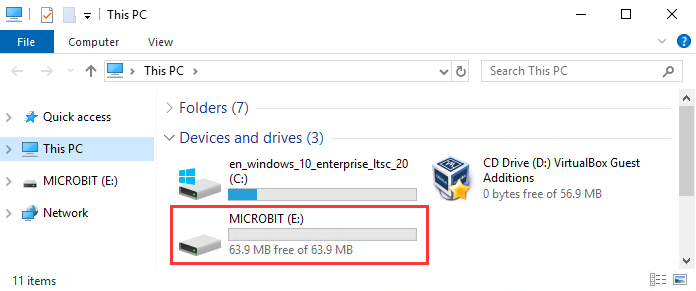

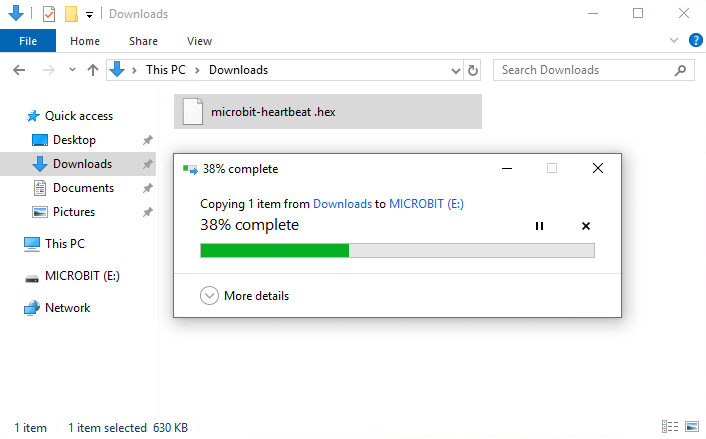

Secondly, if the red LED on the back of the board is on, that means the board is powered. Then Micro: Bit main board V2 will appear on your computer as a driver named ‘MICROBIT’. Please note that it is not an ordinary USB disk as shown below.

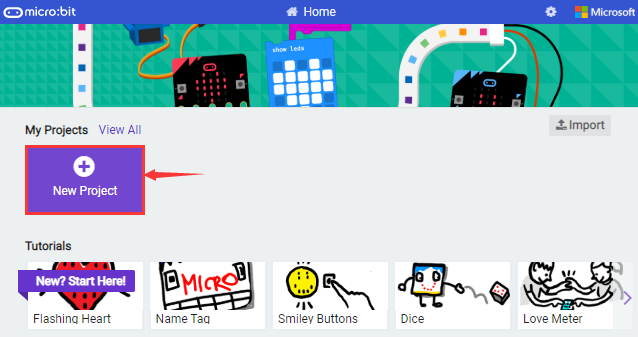

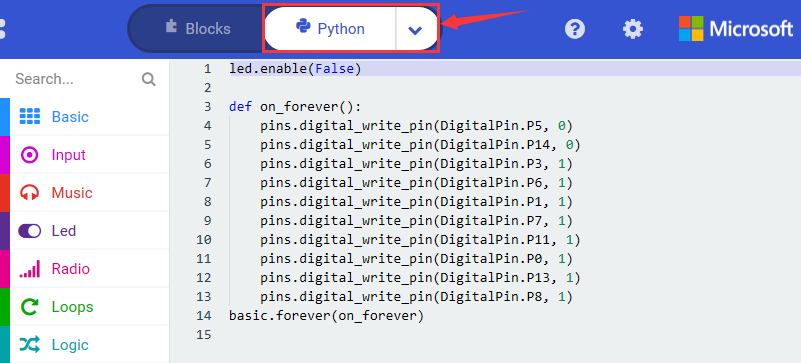

Step 2: write programs

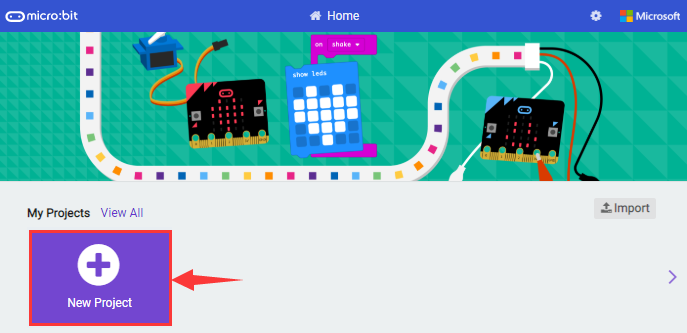

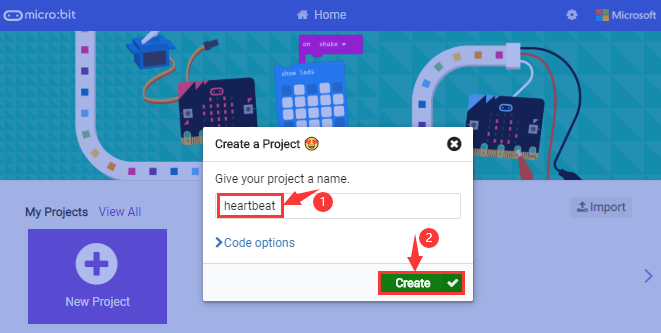

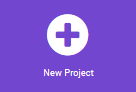

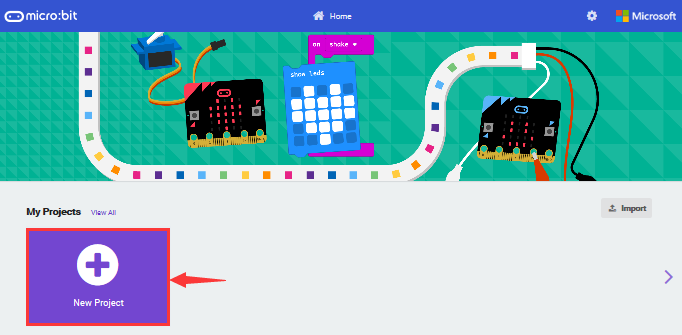

View the link https://makecode.microbit.org/ in your browser;

Click ‘New Project’;

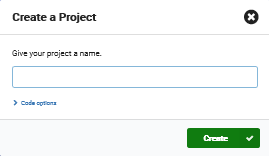

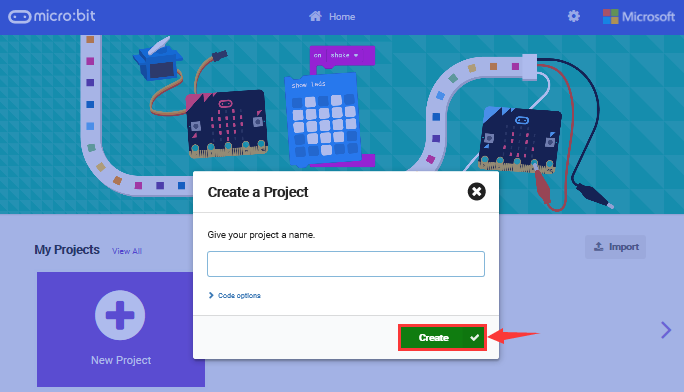

The dialog box‘Create a Project’ appears, fill it with ‘heartbeat’ and click‘Create √’to edit.

(If you are running Windows 10 system, it is also viable to edit on the APP MakeCode for micro:bit , which is exactly like editing in the website. And the link to the APP is :https://www.microsoft.com/zh-cn/p/makecode-for-micro-bit/9pjc7sv48lcx?ocid=badgep&rtc=1&activetab=pivot:overviewtab)

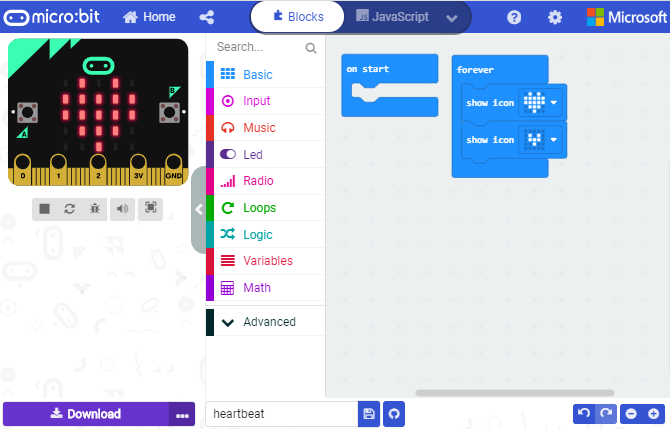

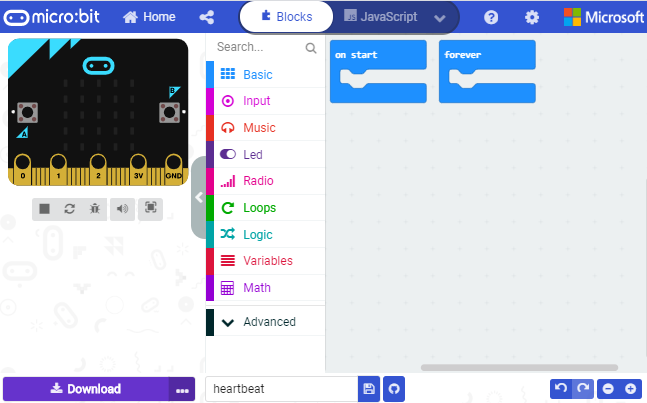

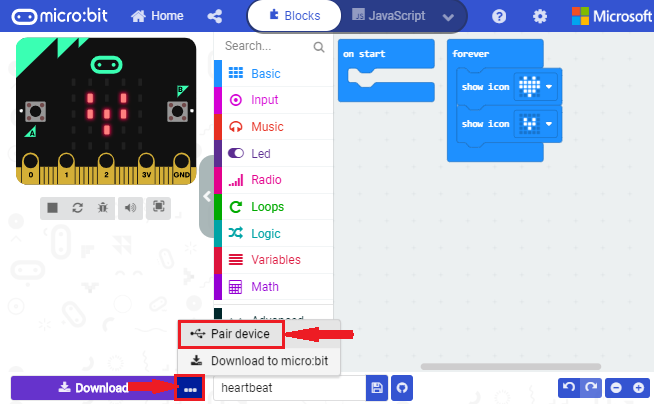

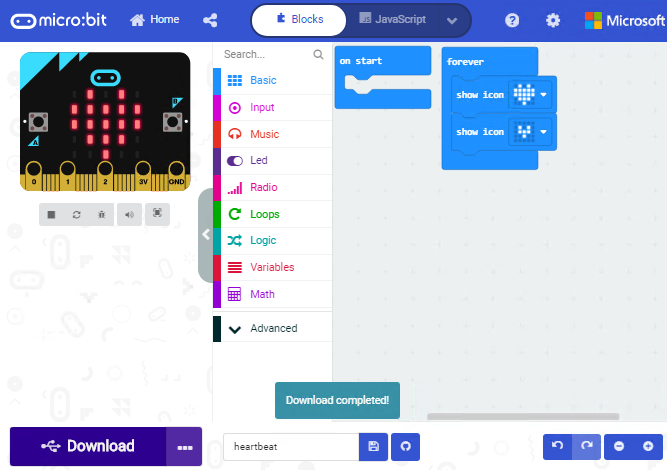

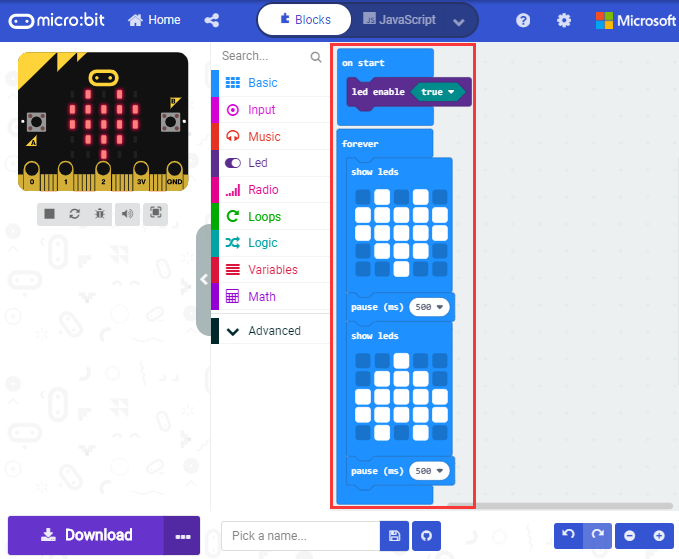

Write a set of micro:bit code. You can drag some modules in the Blocks to the editing area and then run your program in Simulator of MakeCode editor as shown in the picture below which demonstrates how to edit ‘heartbeat’ program .

Step 3: download test code

If your computer is Windows 10 and you have downloaded the APP MakeCode for micro:bit to write program, what you will have to do to download the program to your Micro: Bit main board V2 is merely clicking the ‘Download’ button, then all is done.

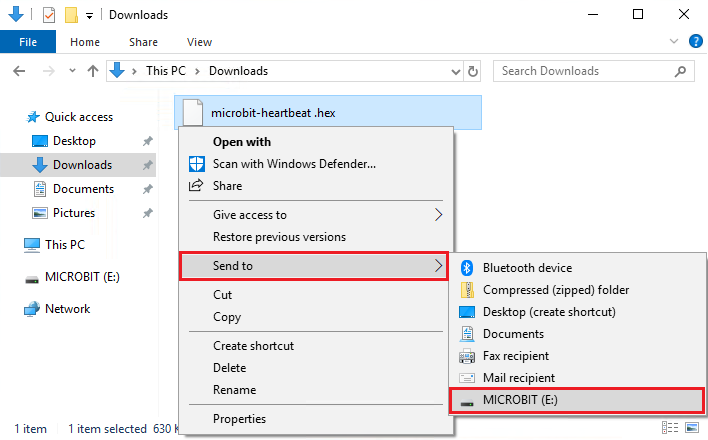

If you are writing programs through the website, following these steps:

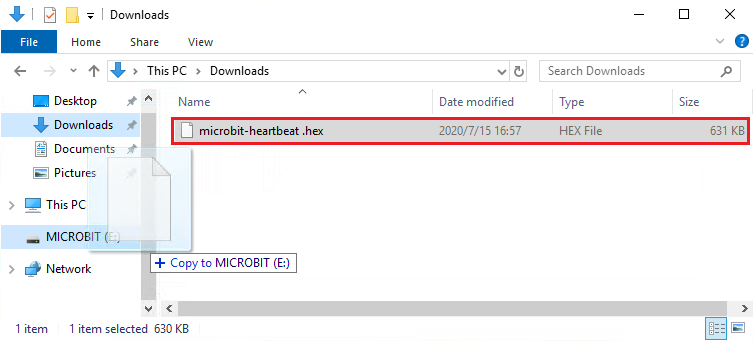

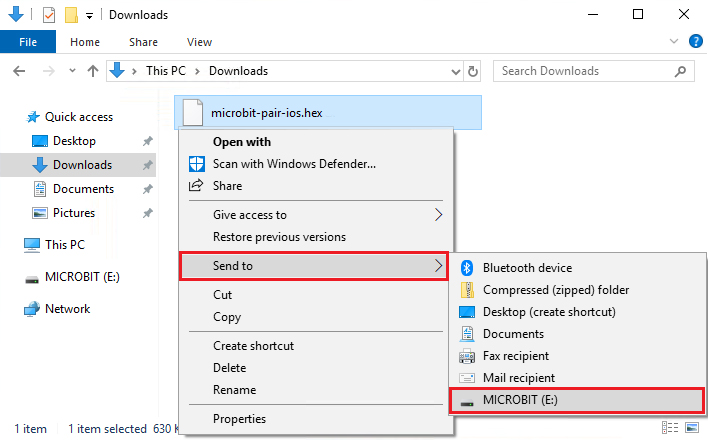

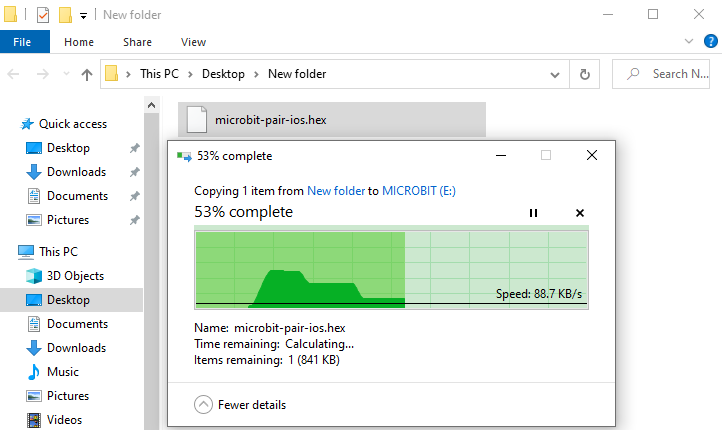

Click the ‘Download’ in the editor to download a “hex” file, which is a compact program format that the Micro: Bit main board can read.Once the hexadecimal file is downloaded, copy it to your board V2 just like the process that you copy the file to the USB driver. If you are running Windows system, you can also right-click and select ‘Send to → MICROBIT (E:) ‘to copy the hex file to the Micro: Bit main board V2.

You can also directly drag the “hex” file onto the MICROBIT (E:) disk.

During the process of copying the downloaded hex file to the Micro: Bit main board V2, the yellow signal light on the back side of the board flashes. When the copy is completed, the yellow signal light will stop flashing and remain on.

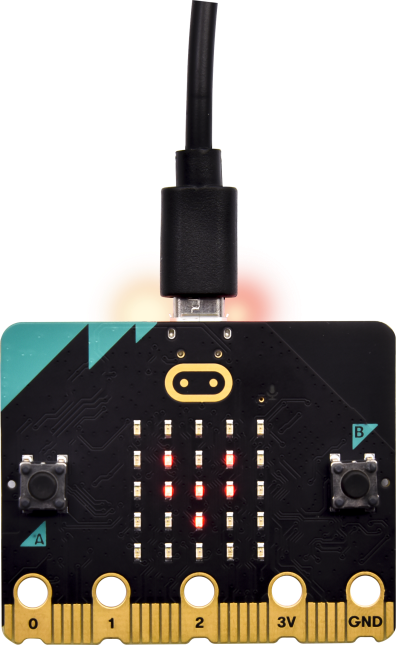

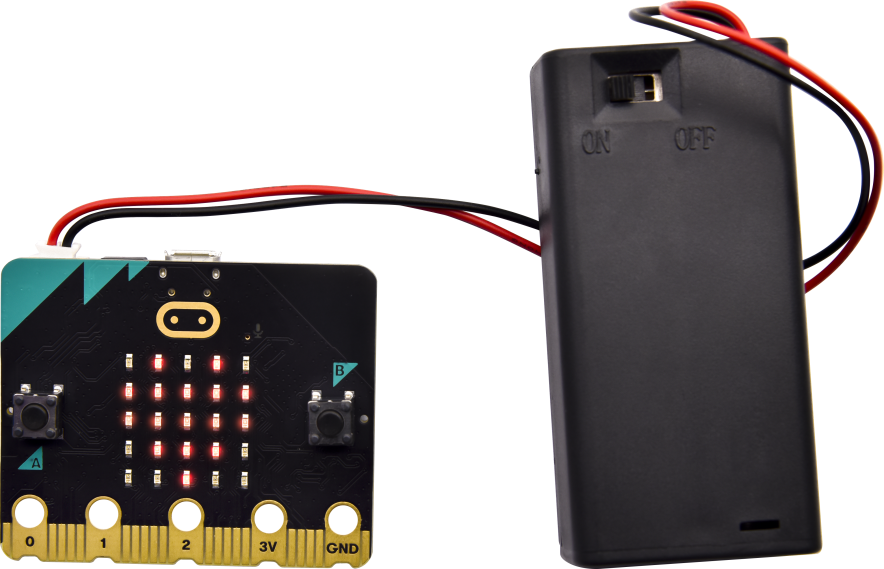

Step 4: run the program

After the program is uploaded to the Micro: Bit main board V2, you could still power it via the USB cable or change to via an external power. The 5 x 5 LED dot matrix on the board displays the heartbeat pattern.

Power via micro USB cable

Power via external power(3V)

Step 5:know about other programming languages

This chapter has described how to use the Micro: Bit main board V2.

But except for the Makecode graphical programming introduced you can also write Micro: Bit programs in other languages. Go to the link: https://microbit.org/code/ to know about other programming languages , or view the link: https://microbit.org/projects/, to find something you want to have a go.

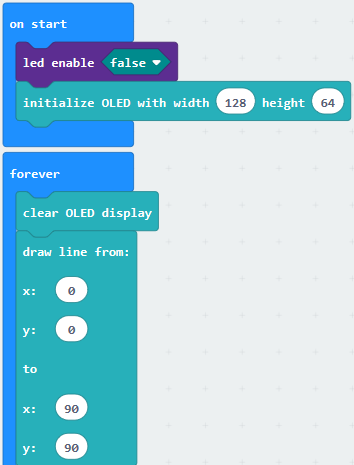

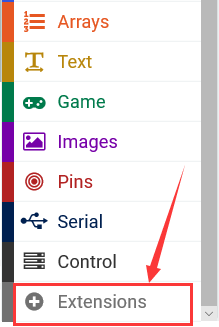

5.2 Makecode:

Browse https://makecode.microbit.org/ and enter Makecode online editor or open the APP MakeCode for micro:bit of Windows 10.

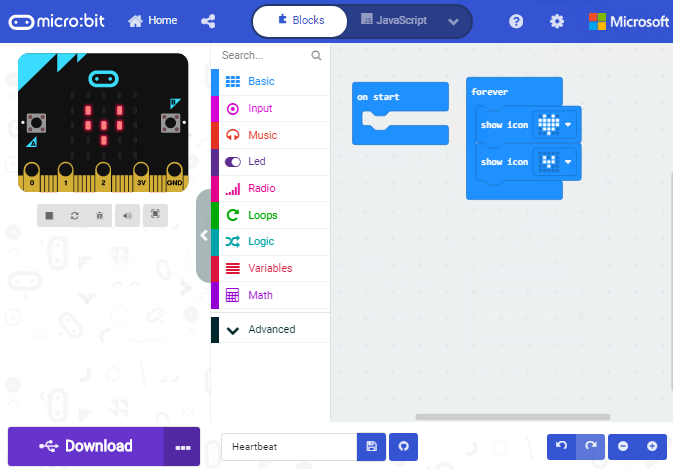

Click“New Project”, and input“heartbeat”,then enter Makecode editor, as shown below:

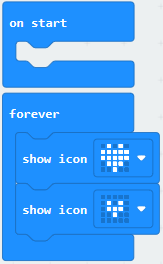

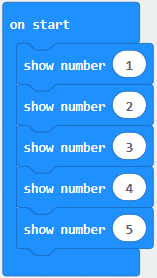

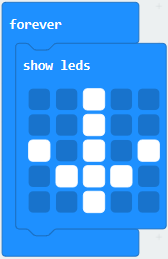

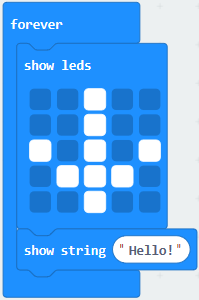

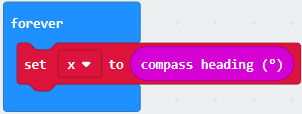

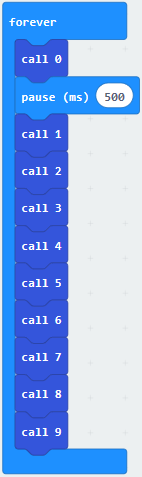

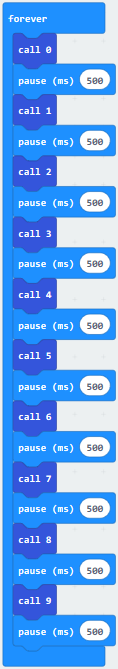

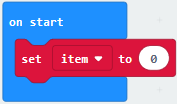

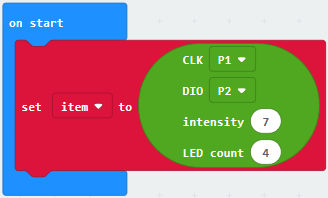

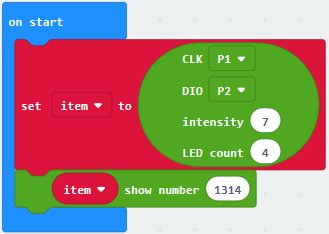

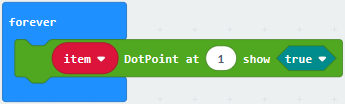

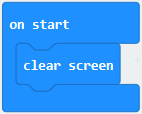

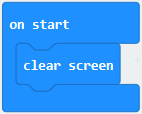

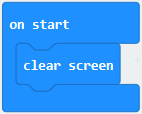

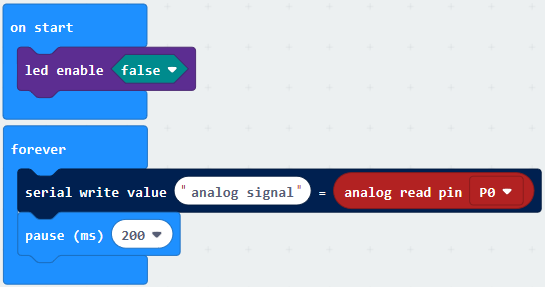

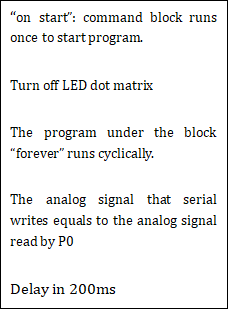

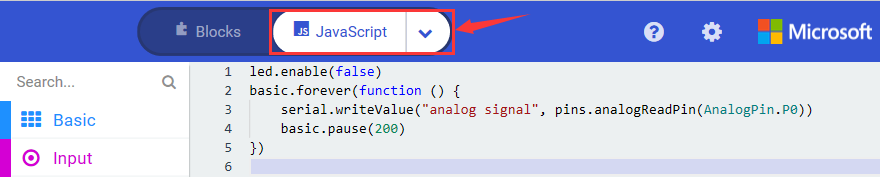

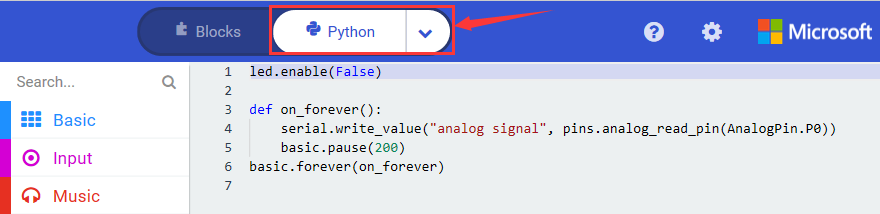

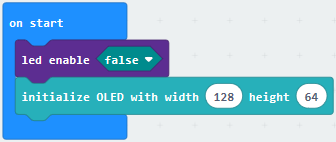

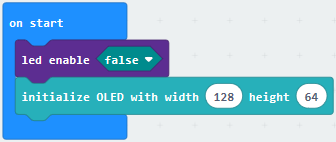

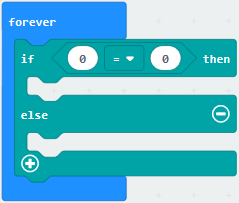

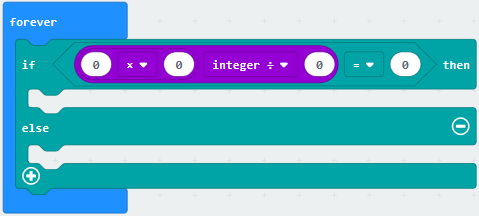

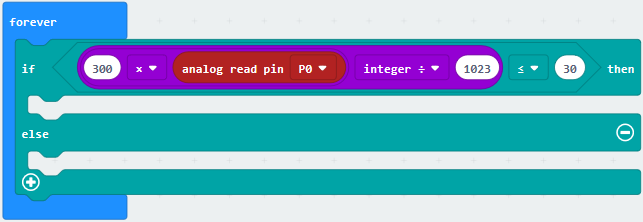

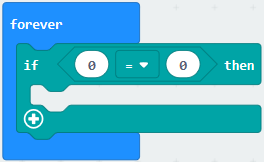

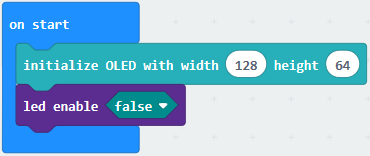

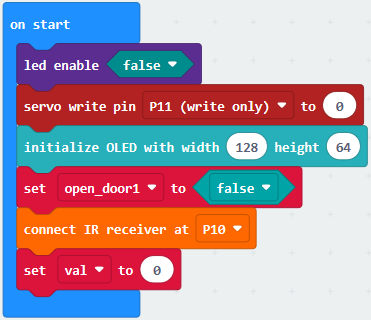

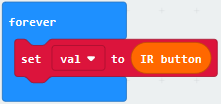

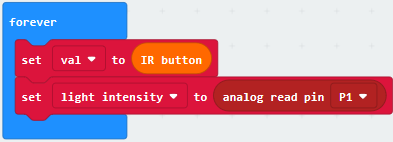

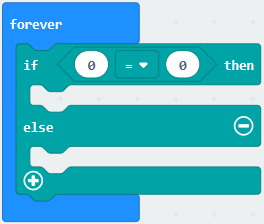

There are blocks“on start”and“forever”in the code editing area.

When the power is plugged or reset,“on start”means that the code in the block only executes once, while“forever”implies that the code runs cyclically.

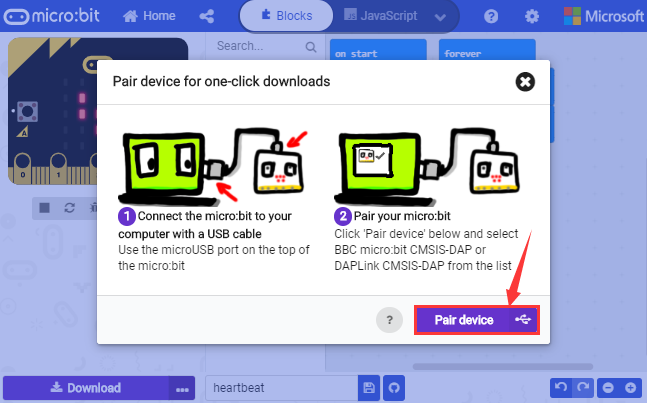

5.3.Quick Download

As mentioned before, if your computer is Windows 10 and you have downloaded the APP MakeCode for micro:bit to write programs, the program written can be quickly downloaded to the Micro: Bit main board V2 by selecting ‘Download’.

While it is a little more trickier if you are using a browser to enter makecode.However, if you use Google Chrome, suitable for Linux,macOS and Windows 10, the process can be quicker too.

We use the webUSB function of Chrome to allow the internet page to access the hardware device connected USB.

You could refer to the following steps to connect and pair devices.

Device pairing

Connect micro:bit to your computer by USB cable. Click“…”beside“Download”and click“Pair device”.

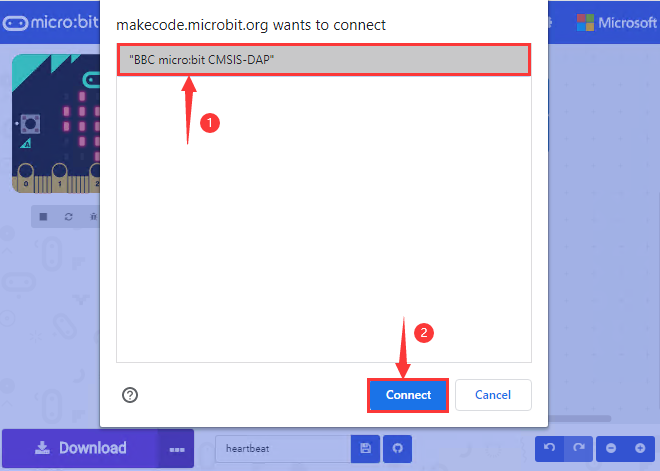

Then click another“Pair device”as shown below.

Then select ‘’BBC micro:bit CMSIS-DPA” and click “Connect”. If ‘’BBC micro:bit CMSIS-DPA”does not show up for selection, please refer to:https://makecode.microbit.org/device/usb/webusb/troubleshoot

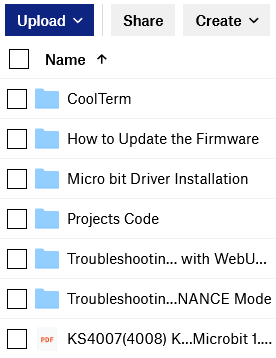

We also provide  in the resource link https://fs.keyestudio.com/KS4007-4008

in the resource link https://fs.keyestudio.com/KS4007-4008

What’s more, if you don’t know how to update the firmware of micro:bit, refer to the link: https://microbit.org/guide/firmware/ or browse folder we provide.

we provide.

Then click”Download”. The program is directly downloaded to Micro: Bit main board V2 and the sentence “Download completed!” appears.

5.4 Resources and test code

Tools ,test code and other resources can be downloaded via the link https://fs.keyestudio.com/KS4007-4008 and it contains following files:

5.5 Input test code

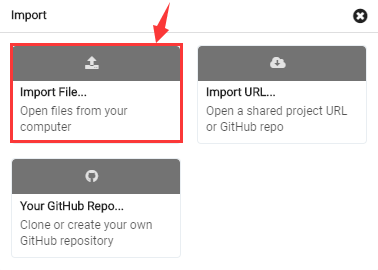

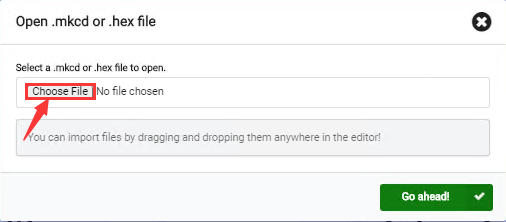

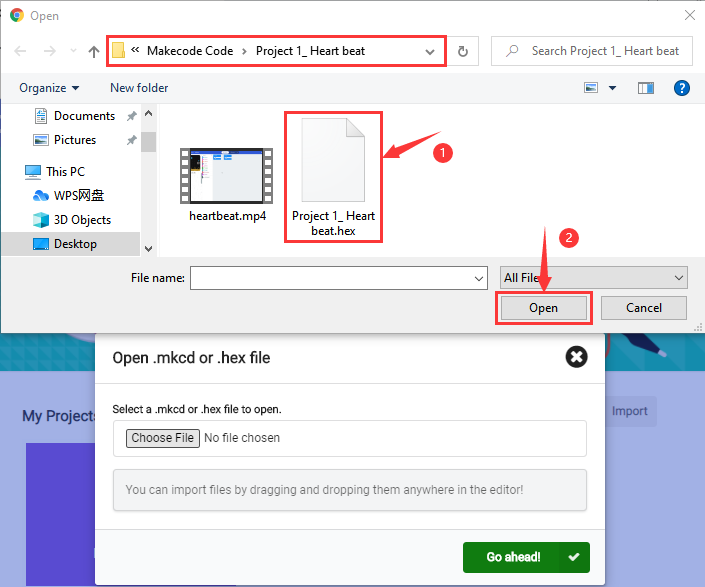

We provide hexadecimal code files (project files) for each project.The file contains all the contents of the project and can be imported directly, or you can manually drag the code blocks to complete the program for each project.

For simple projects, dragging a block of code to complete the program is recommended. For complex projects, it is recommended to conduct the program by importing the hexadecimal code file we provide.

Let’s take the “Heatbeat” project as an example to show how to load the code.

Open the Web version of Makecode or the Windows 10 App version of Makecode.

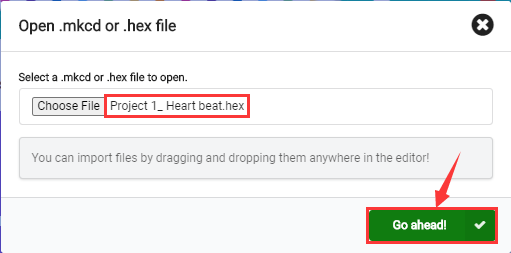

Click “Import File”;

Select“ …/Makecode Code/Project 1_ Heart beat/Project 1_ Heart beat.hex” . Then click “Go ahead”.

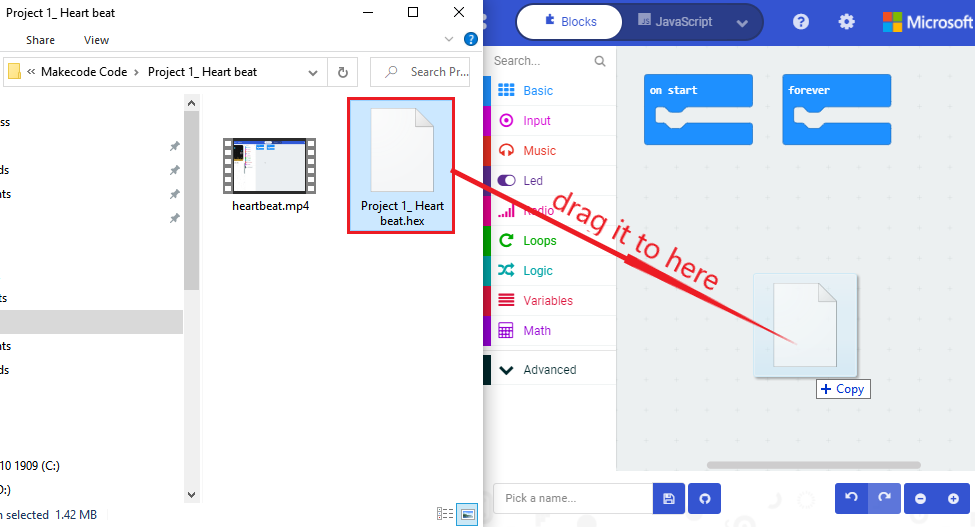

In addition to importing the test code file provided into the Makecode compiler above, you can also drag the the test code file provided into the code editing area of the Makecode compiler, as shown in the figure below:

After a few seconds, it is done.

Note: if your computer system is Windows7 or 8 instead of Windows 10, the pairing cannot be done via Google Chrome. Therefore, digital signal or analog signal of sensors and modules cannot be shown on the serial port simulator.

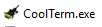

However, you need to read the corresponding digital signal or analog signal. So what can we do? You can use the CoolTerm software to read the serial port data of the micro:bit. Next chapter is about how to install CoolTerm.

5.6 CoolTerm Installation

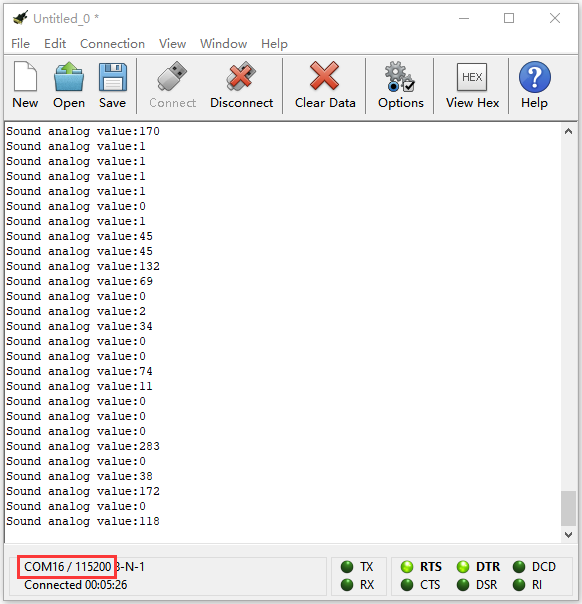

CoolTerm program is used to read the data on serial port.

Download CoolTerm program:

https://freeware.the-meiers.org/

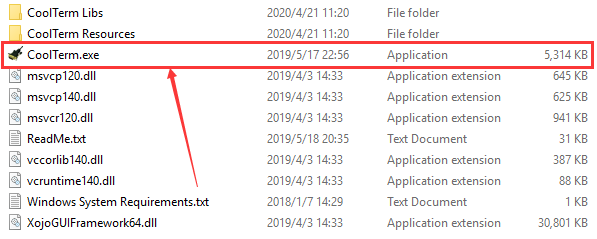

After the download, we need to install CoolTerm program file, below is Window system taken as an example.

Choose“win”to download the zip file of CoolTerm

Unzip file and open it. (also suitable for Mac and Linux system)

(2)Double-click  .

.

The functions of each button on the Toolbar are listed below:

http://wiki.keyestudio.com/index.php/File:IDE.png

ICON |

FUNCTION |

|---|---|

|

Open up a new Terminal |

|

Open a saved Connection |

|

Save the current Connection to disk |

|

Open the Serial Connection |

|

Close the Serial Connection |

|

Clear the Received Data |

|

Open the Connection Options Dialog |

|

Display the Terminal Data in Hexadecimal Format |

|

Display the Help Window |

6. Projects

(Note: project 1 to 12 will be conducted with the built-in sensors and LED dot matrix of the Micro:bit main board V2)

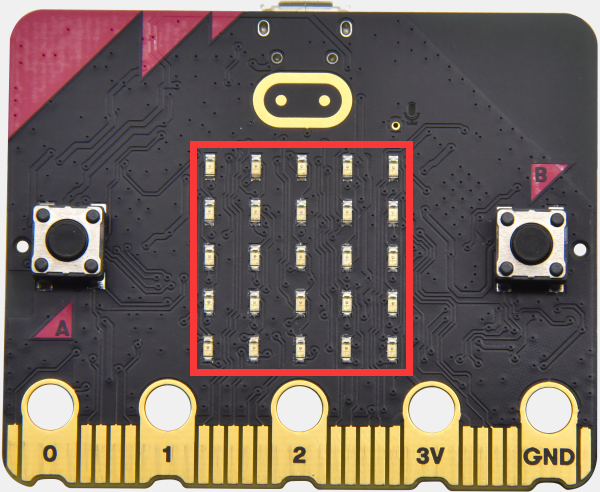

Project 1: Heartbeat

( 1 )Project Description

This project is easy to conduct with a micro:bit V2 main board, a Micro USB cable and a computer. The micro:bit LED dot matrix will display a relatively big heart-shaped pattern and then a smaller one. This alternative change of this pattern is like heart beating. This experiment serves as a starter for your entry to the programming world.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3)Test Code:

Attach the Micro:bit main board V2 to your computer via the Micro USB cable and begin editing.

Firstly, click”basic”module and find and drag the block “show icon “ to module “forever”;

“ to module “forever”;

Secondly, click”basic”module again and find and drag the block “show icon  “ to module “forever”and click the little triangle to select “show icon

“ to module “forever”and click the little triangle to select “show icon  ”;

”;

Secondly, click”basic”module and find and drag the block” ”to the code block and click the littler triangle to select 500;

”to the code block and click the littler triangle to select 500;

Complete Program:

Note: The “on start”means that the code in the block only executes once, while“forever”implies that the code runs cyclically.

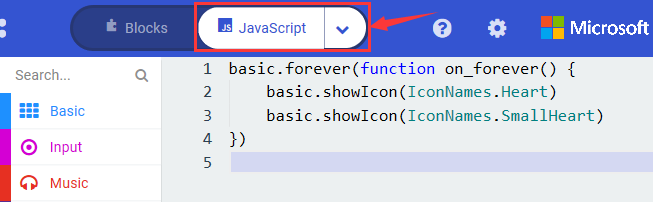

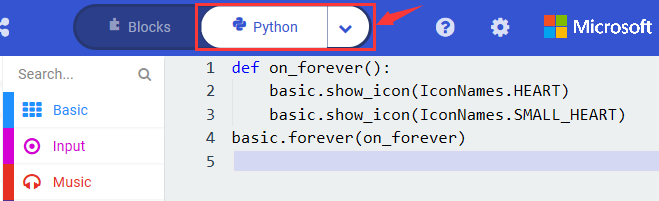

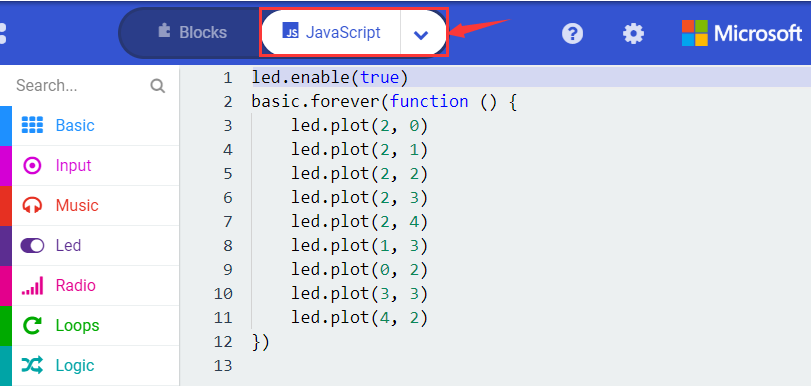

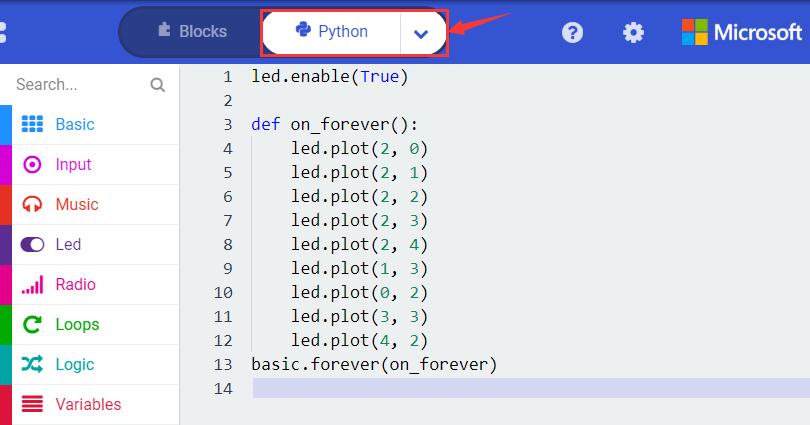

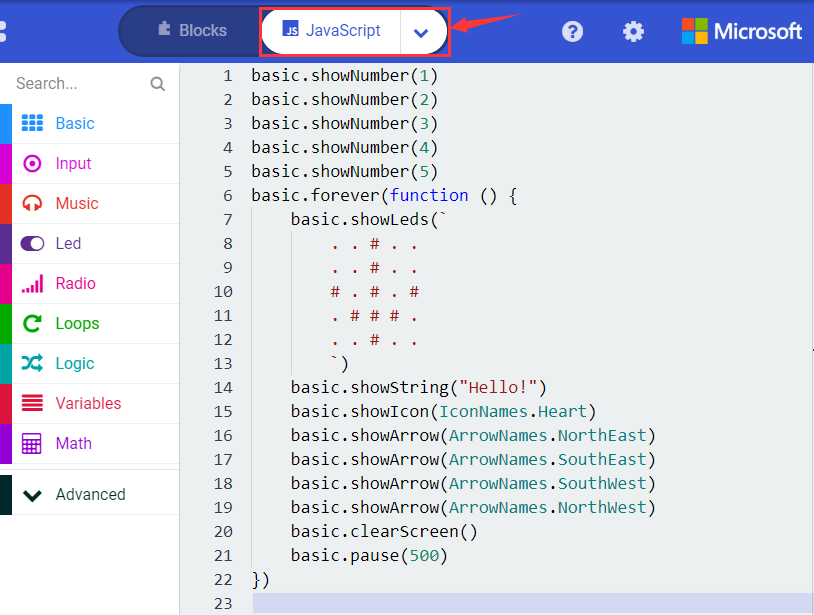

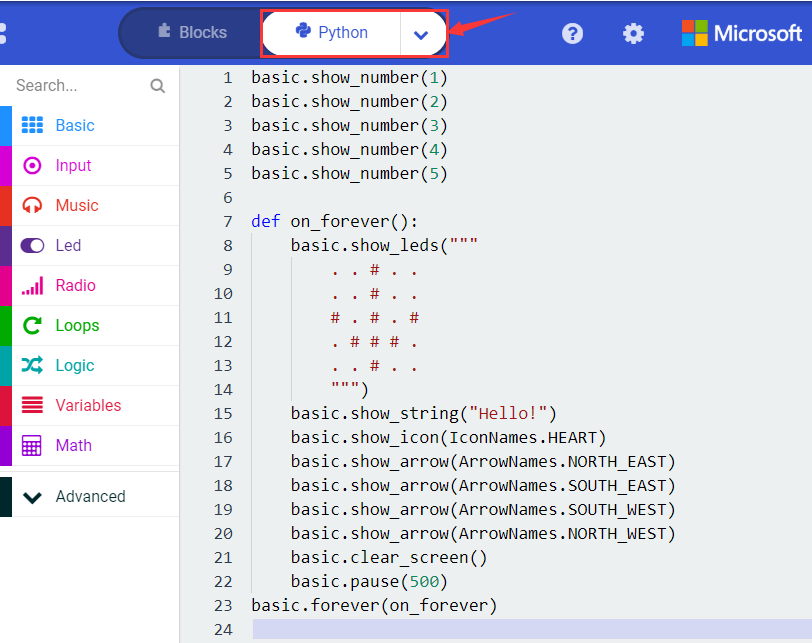

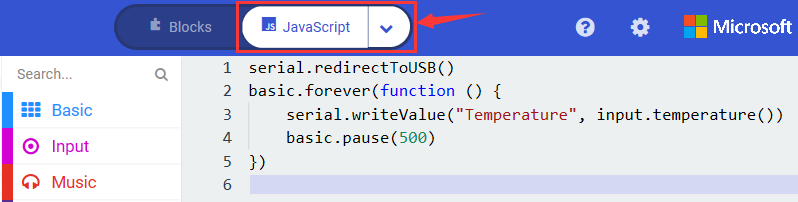

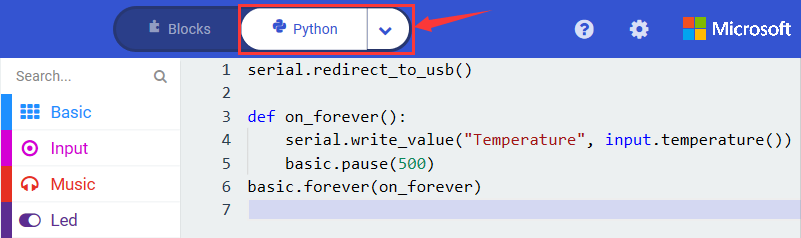

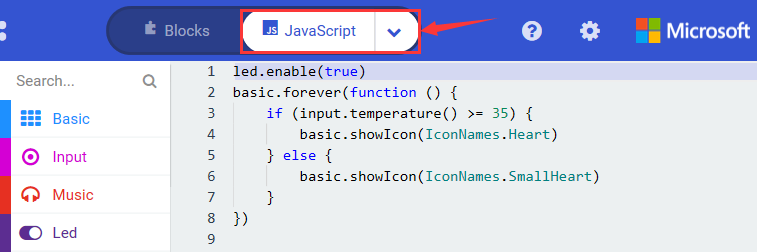

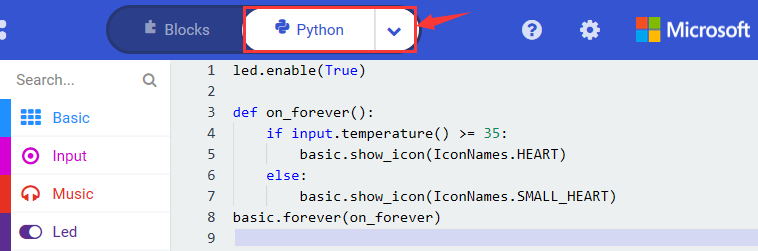

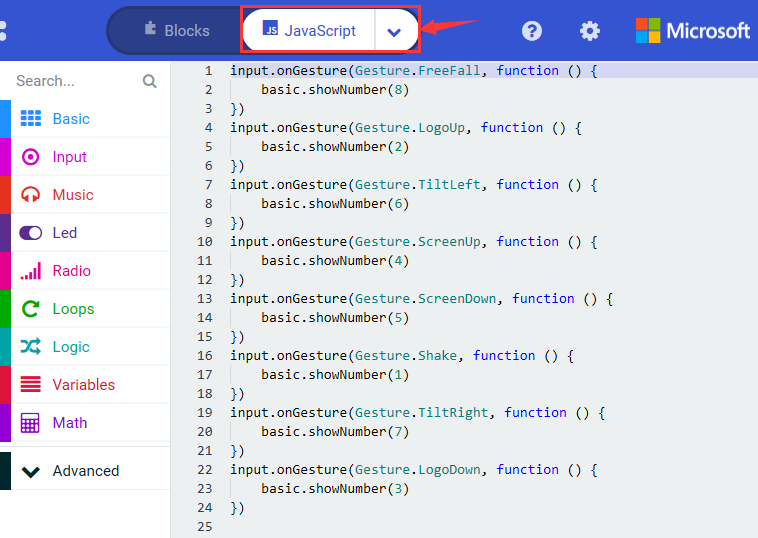

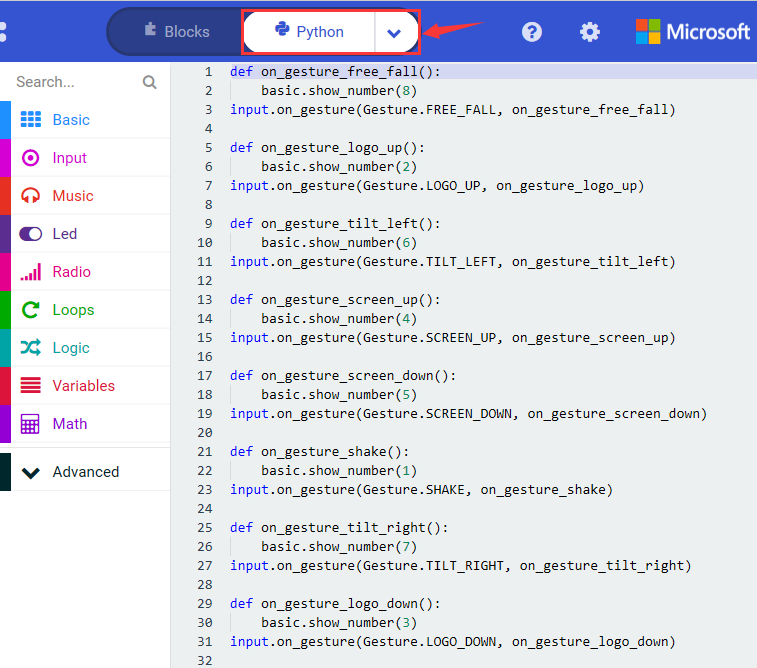

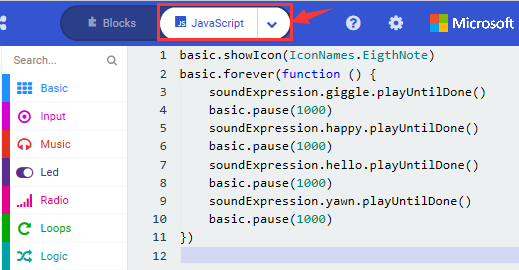

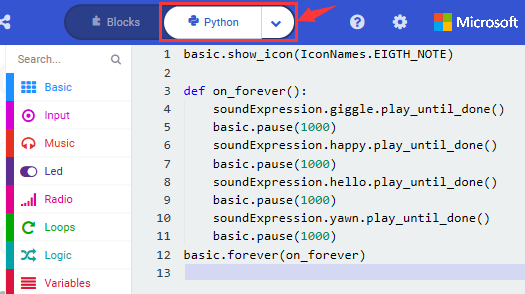

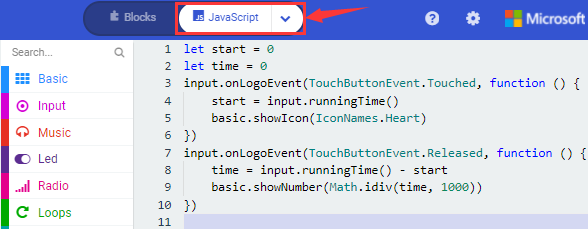

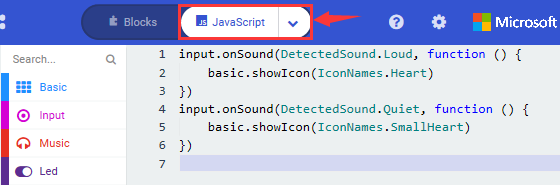

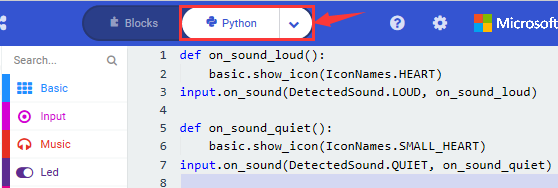

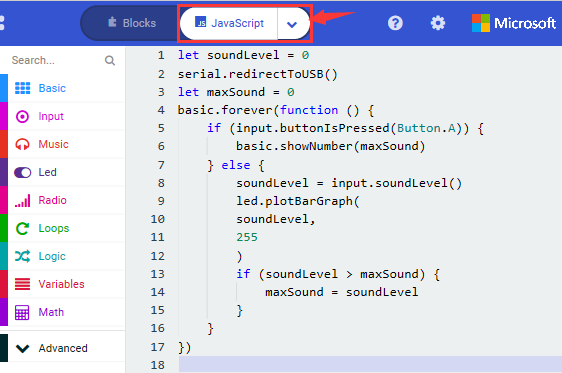

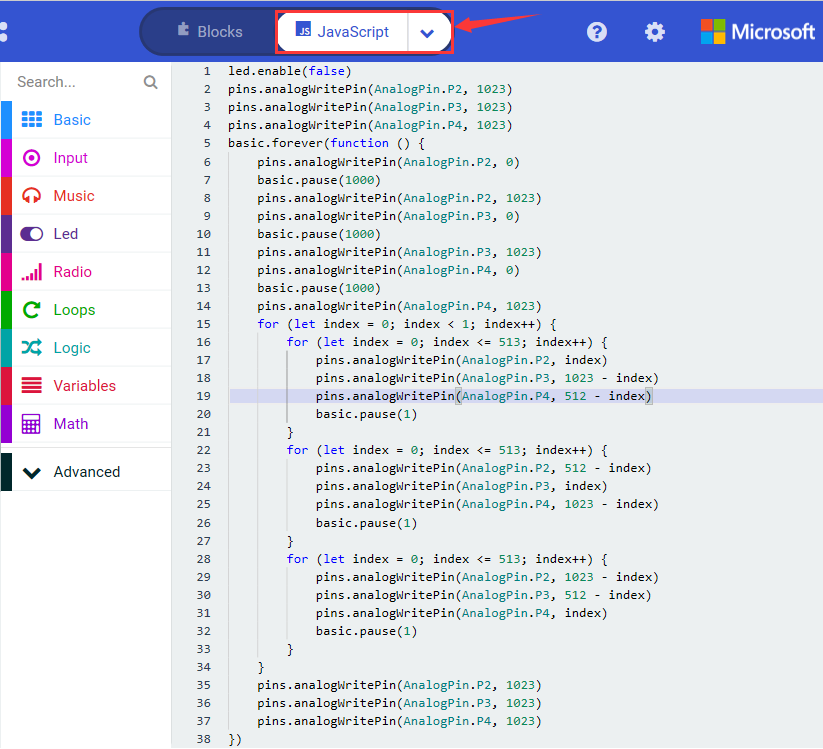

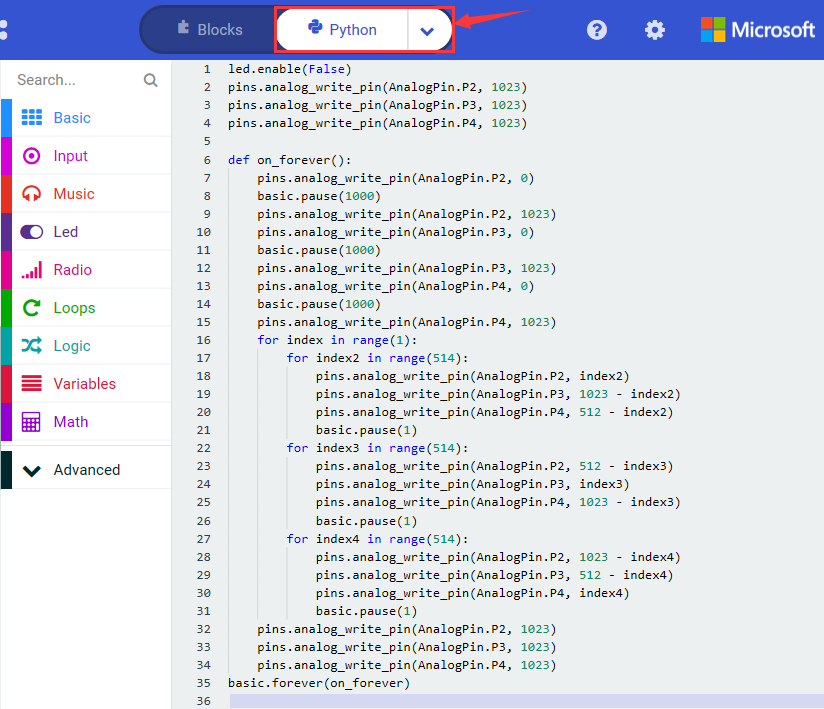

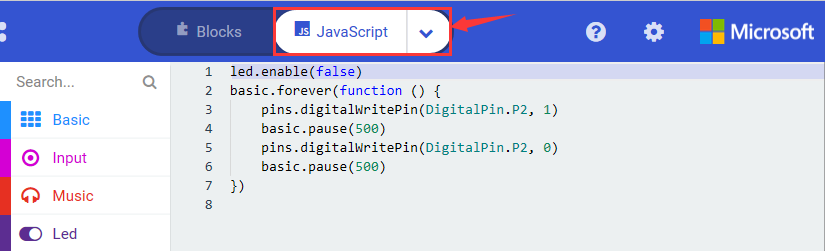

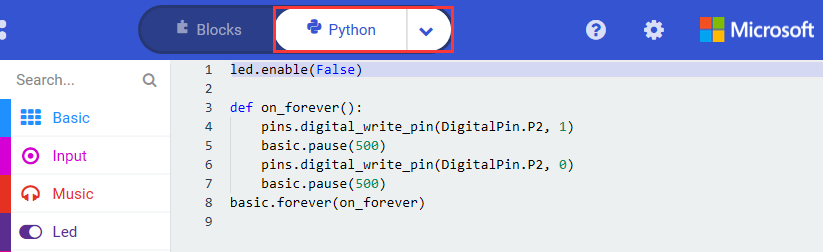

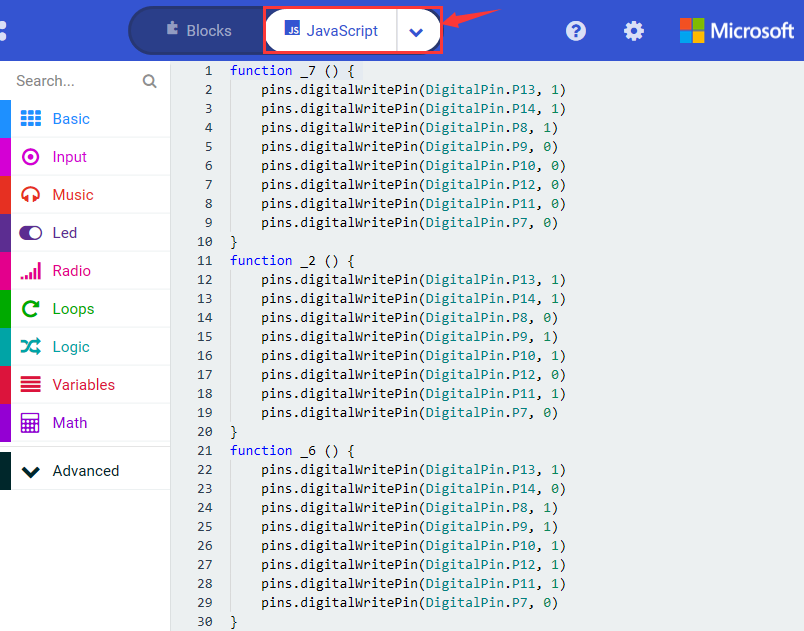

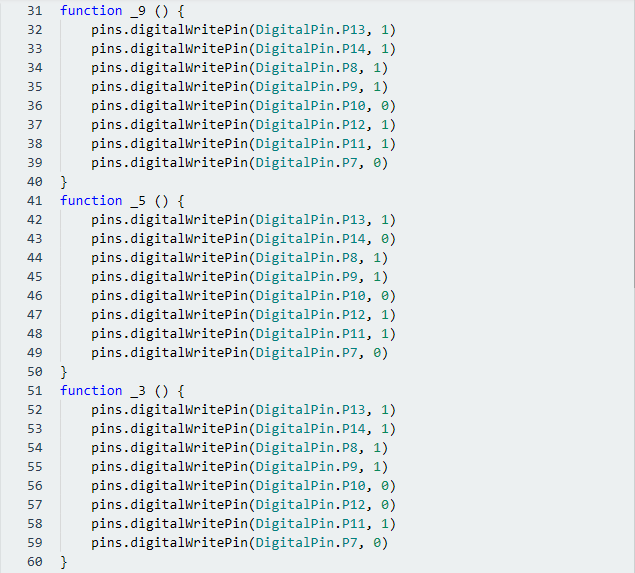

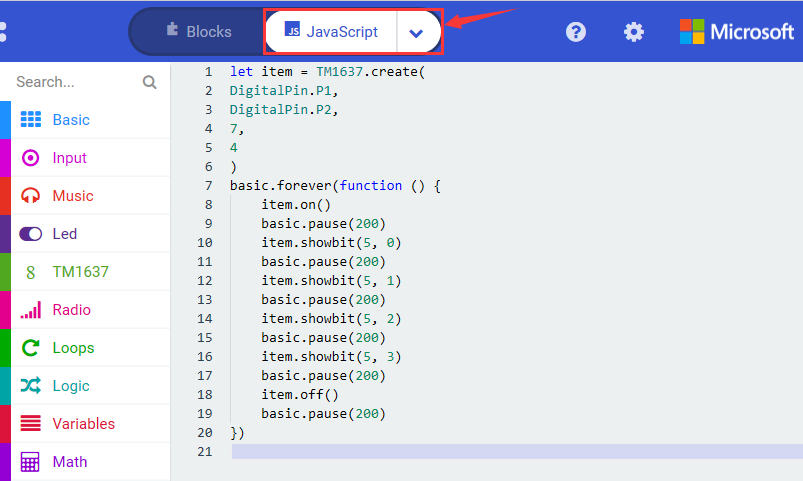

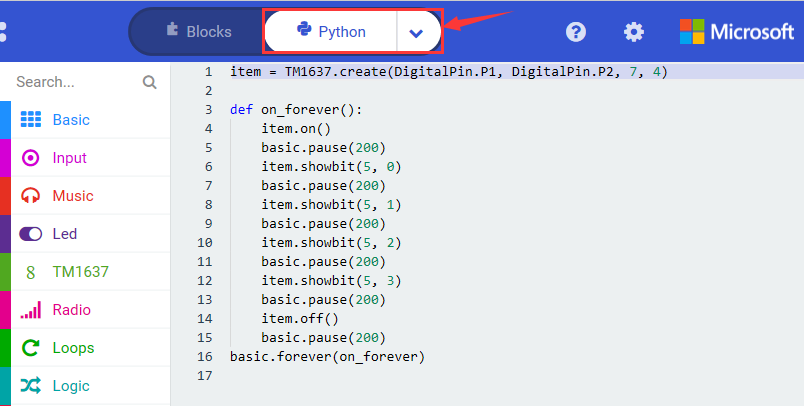

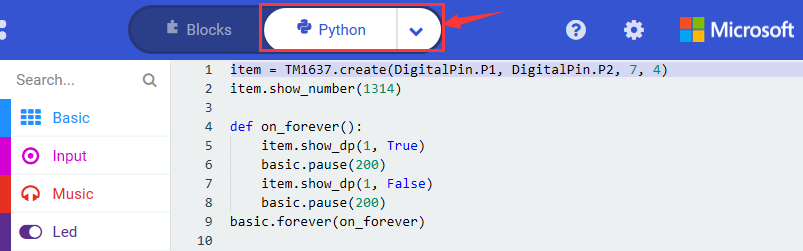

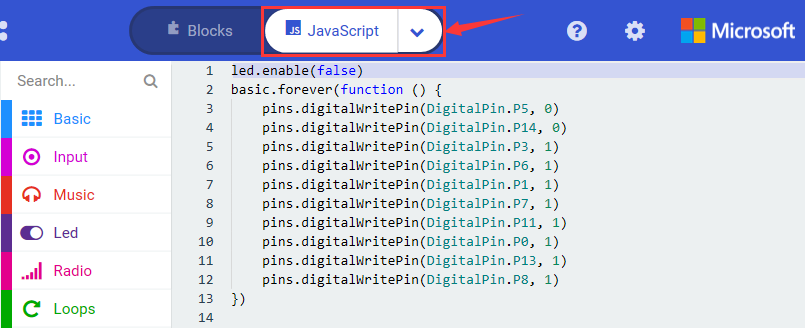

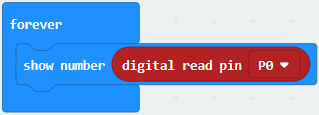

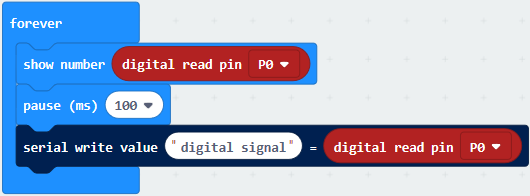

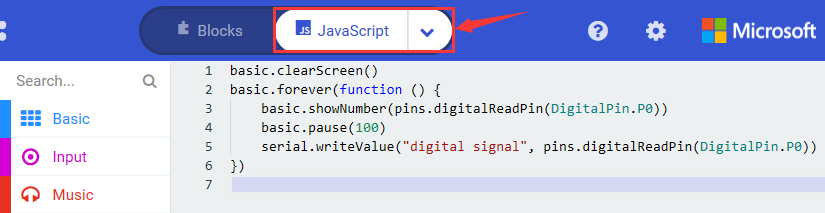

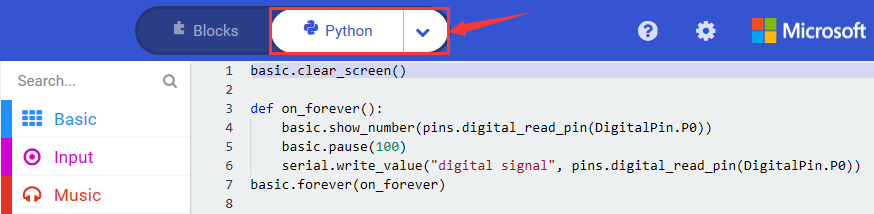

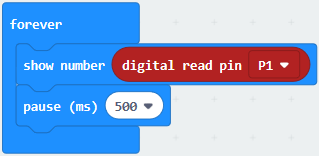

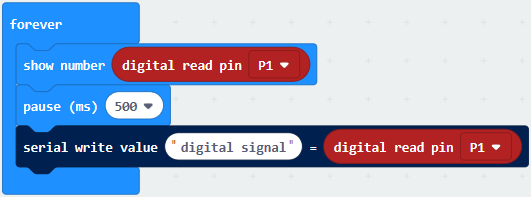

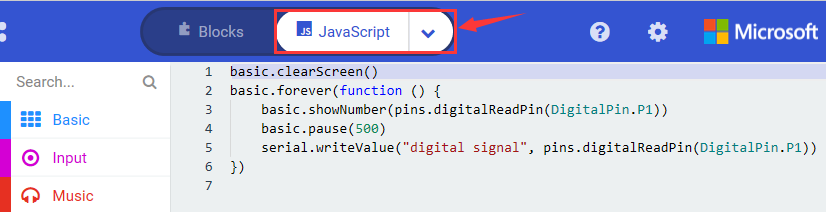

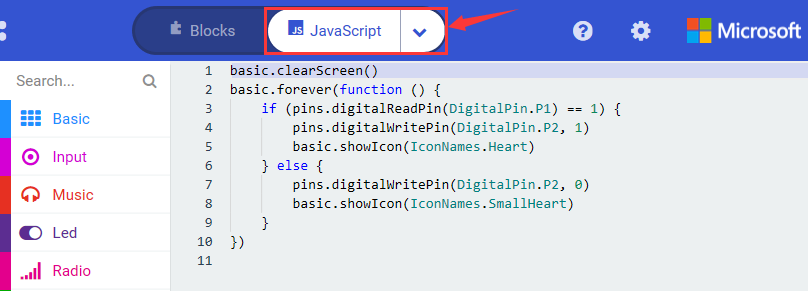

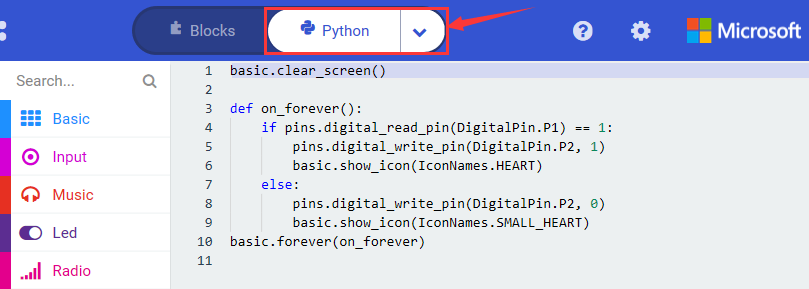

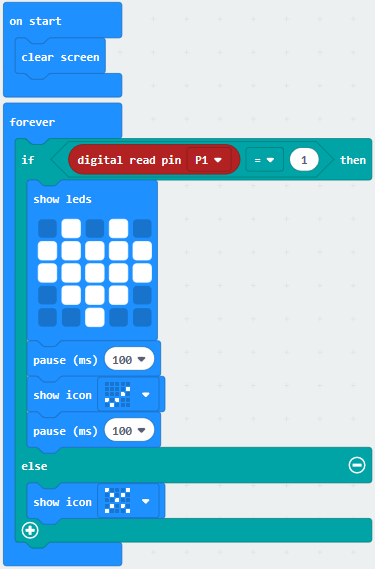

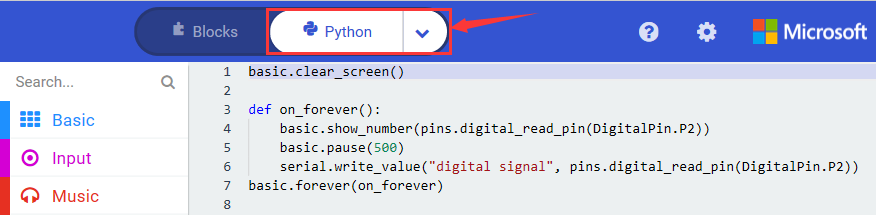

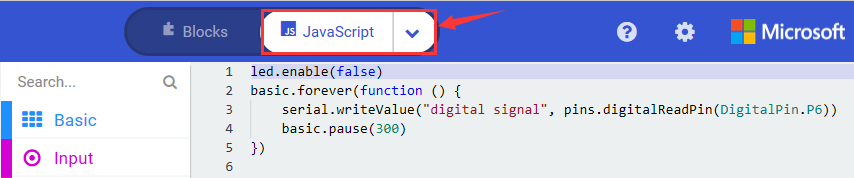

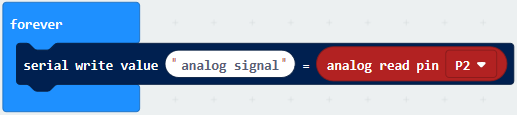

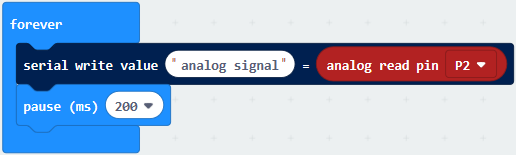

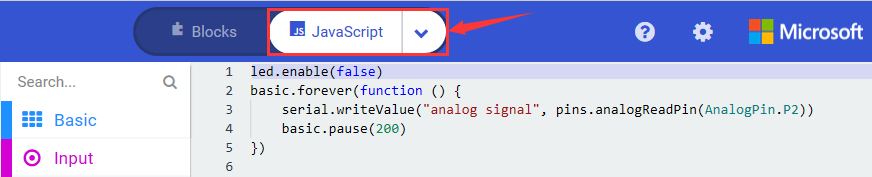

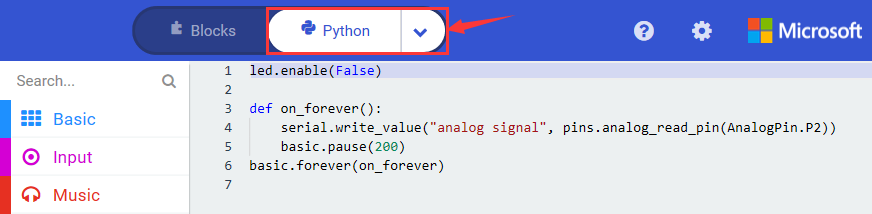

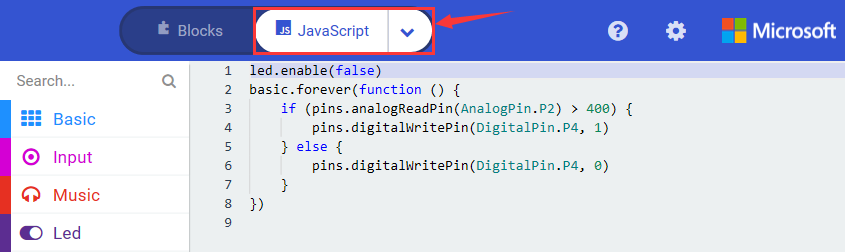

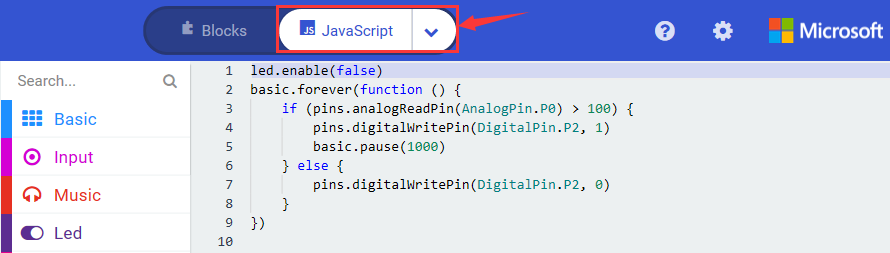

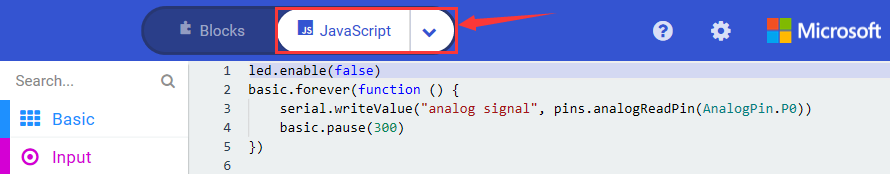

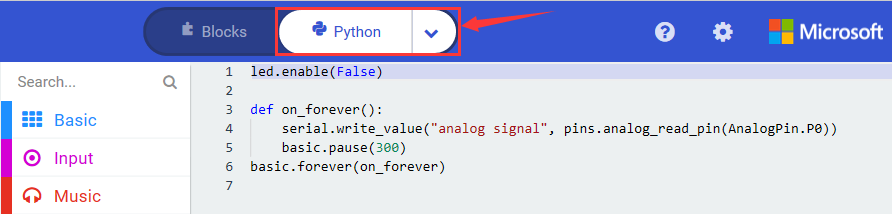

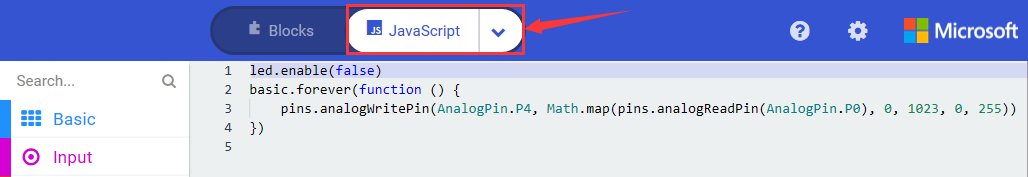

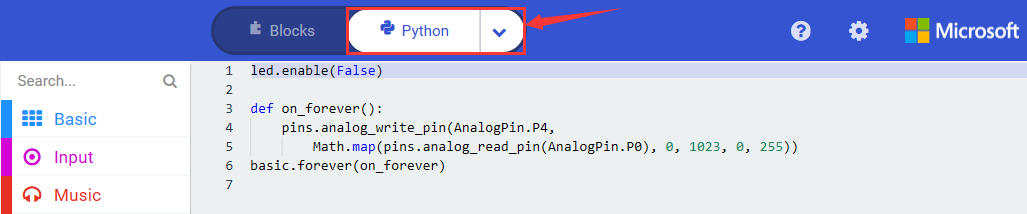

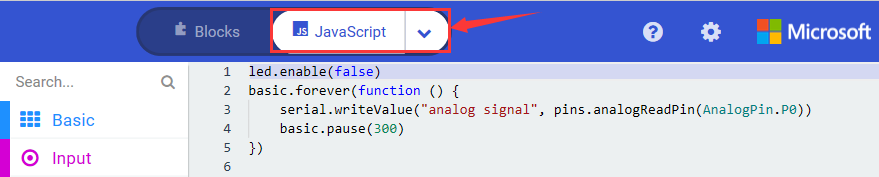

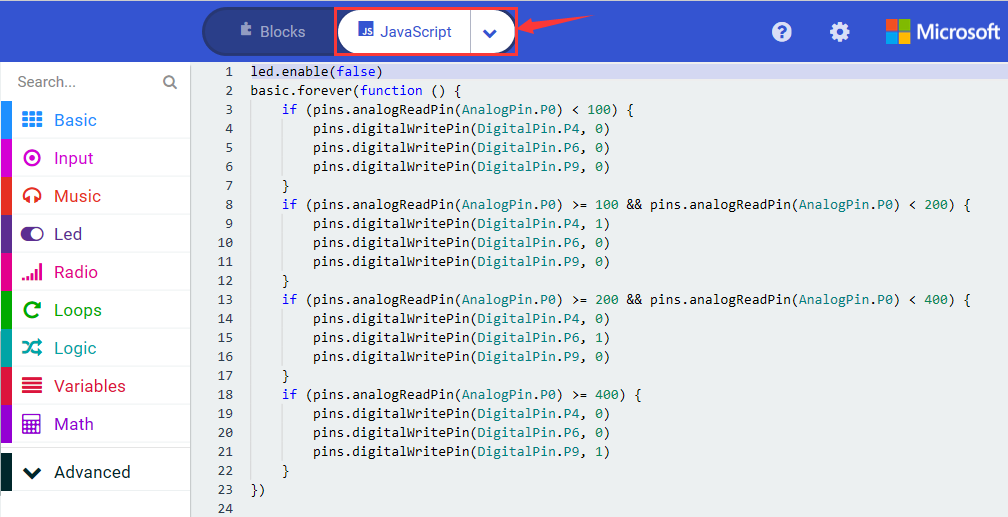

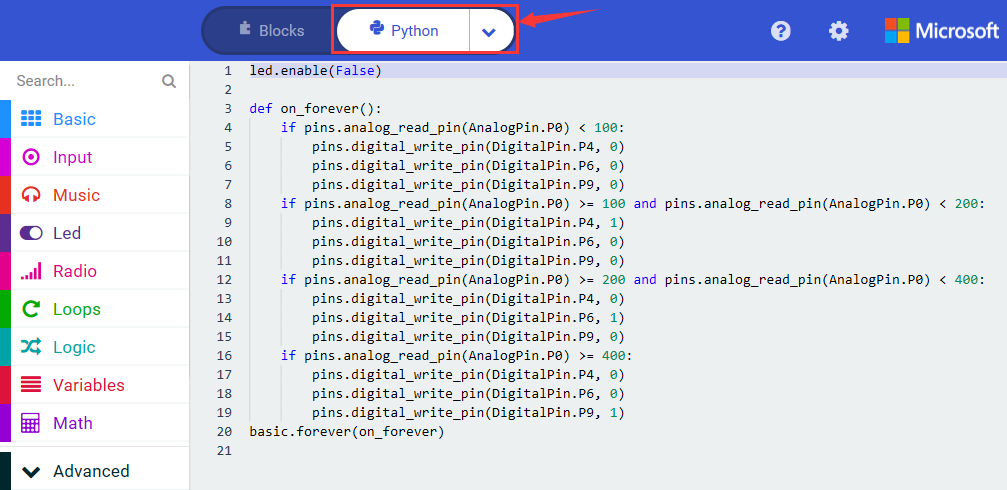

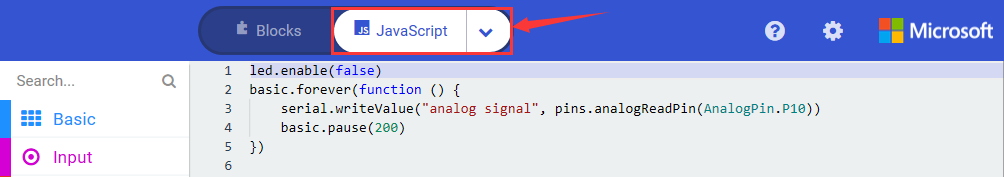

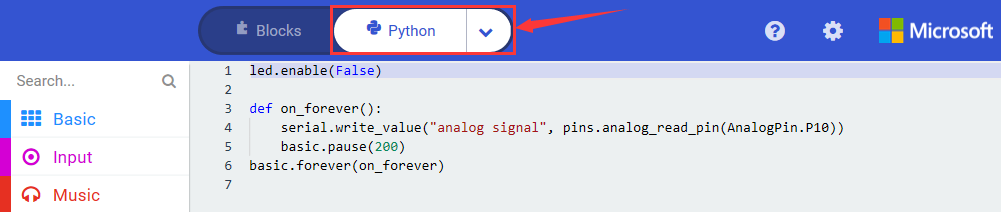

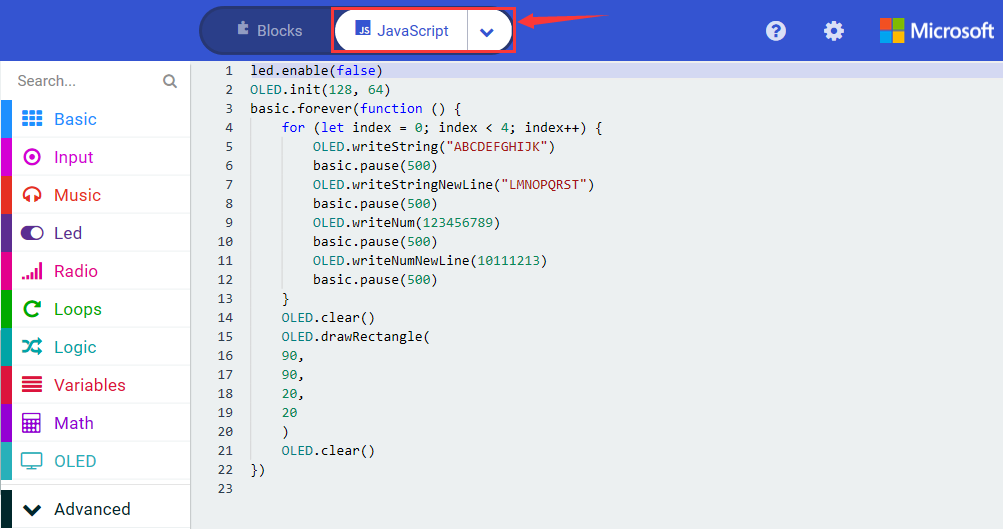

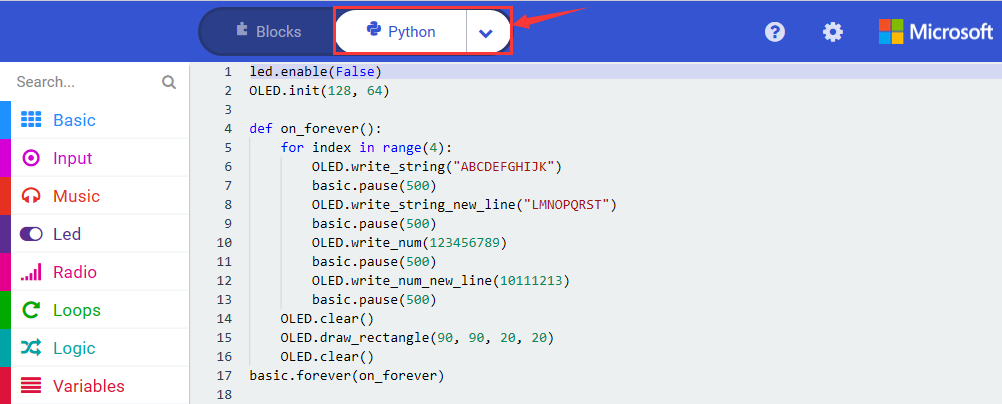

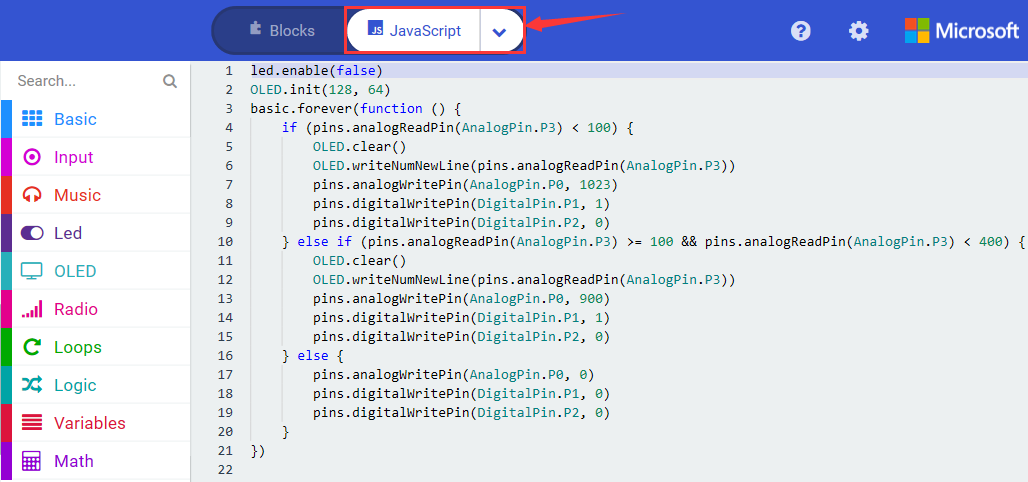

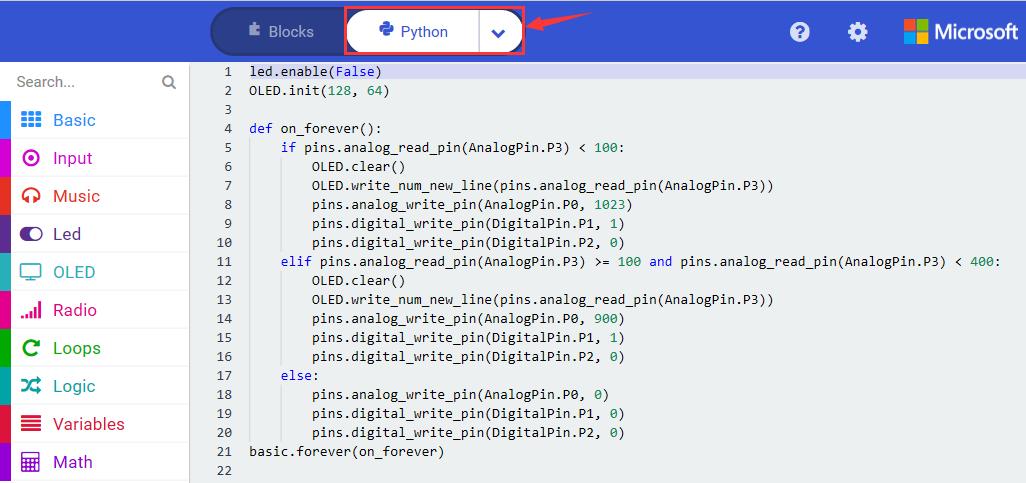

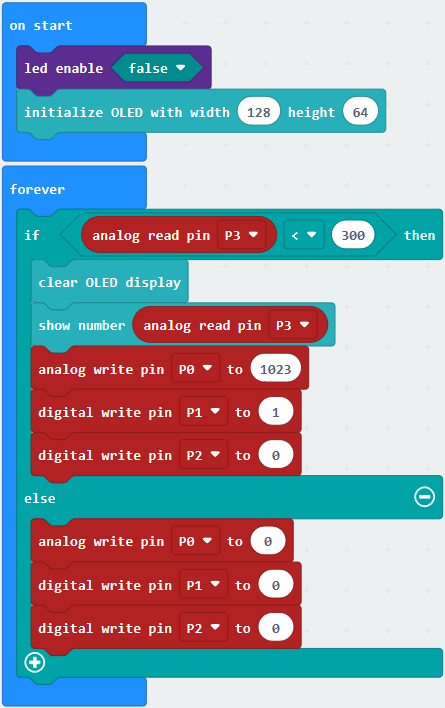

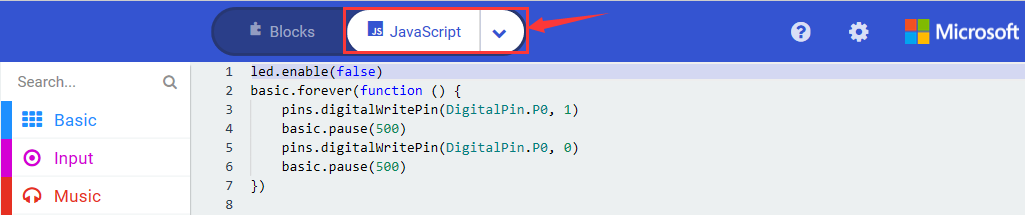

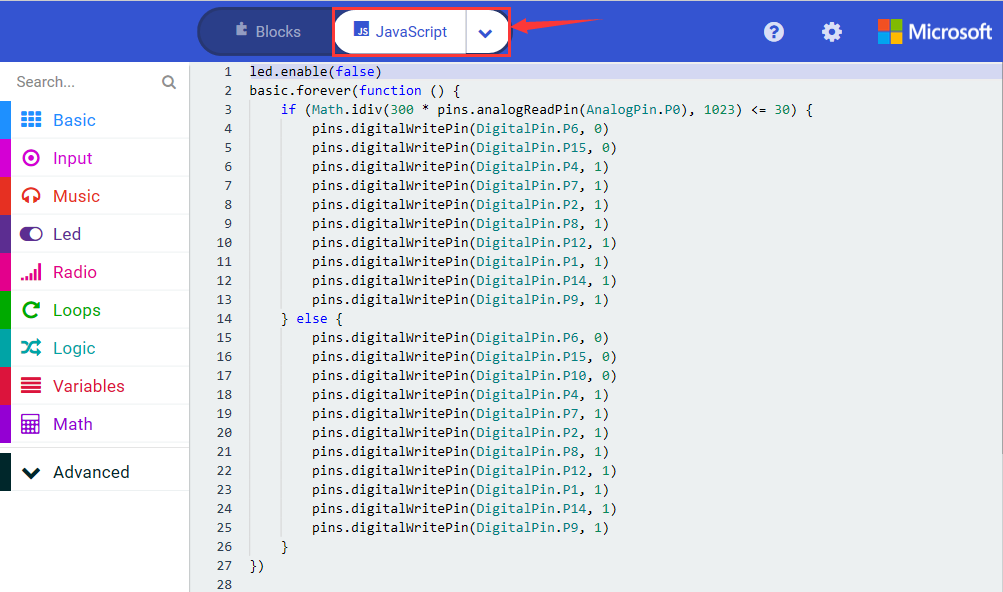

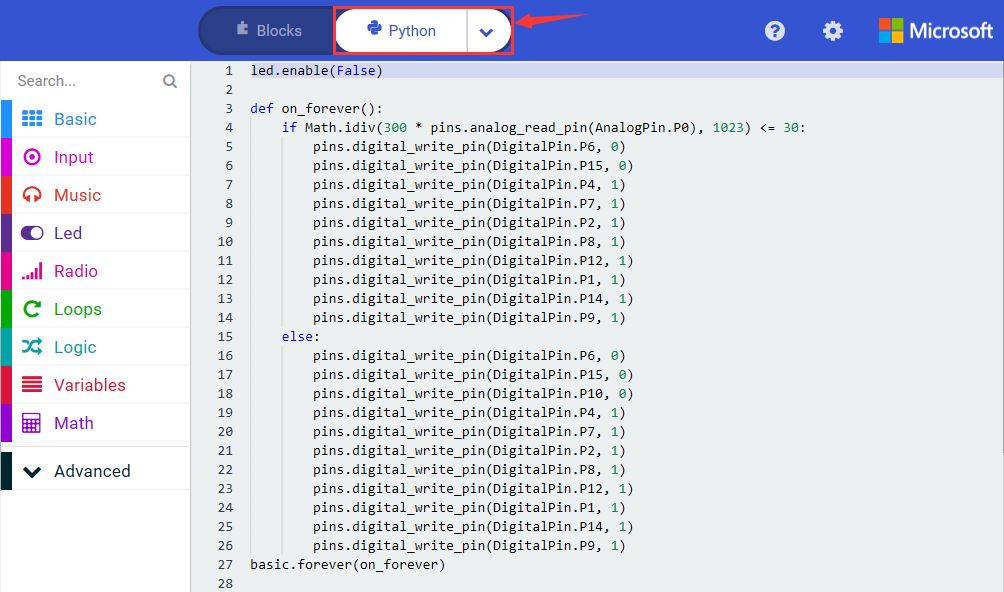

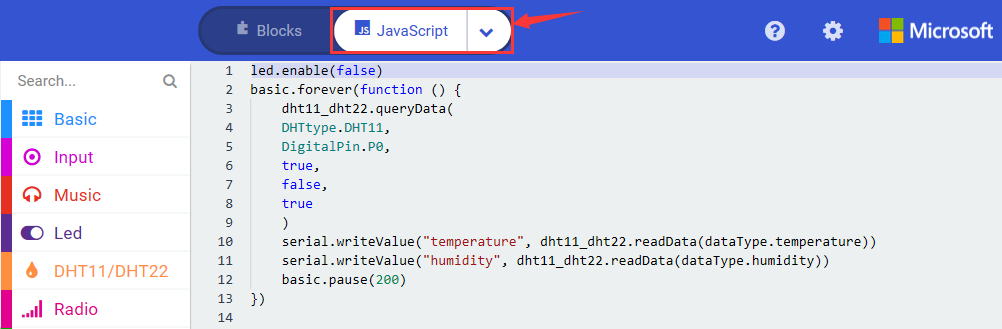

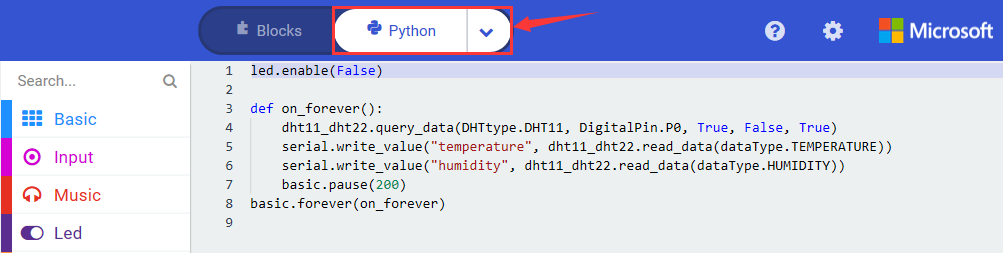

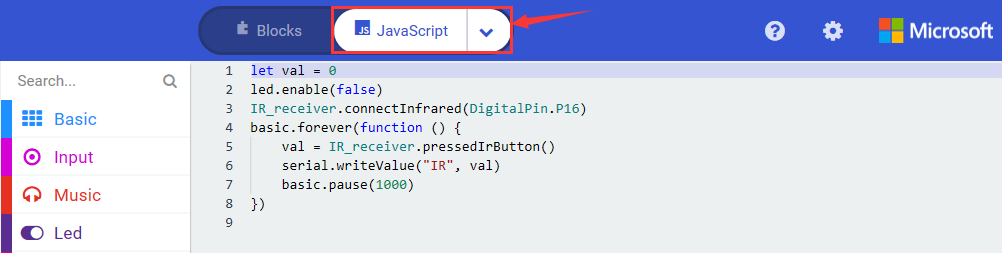

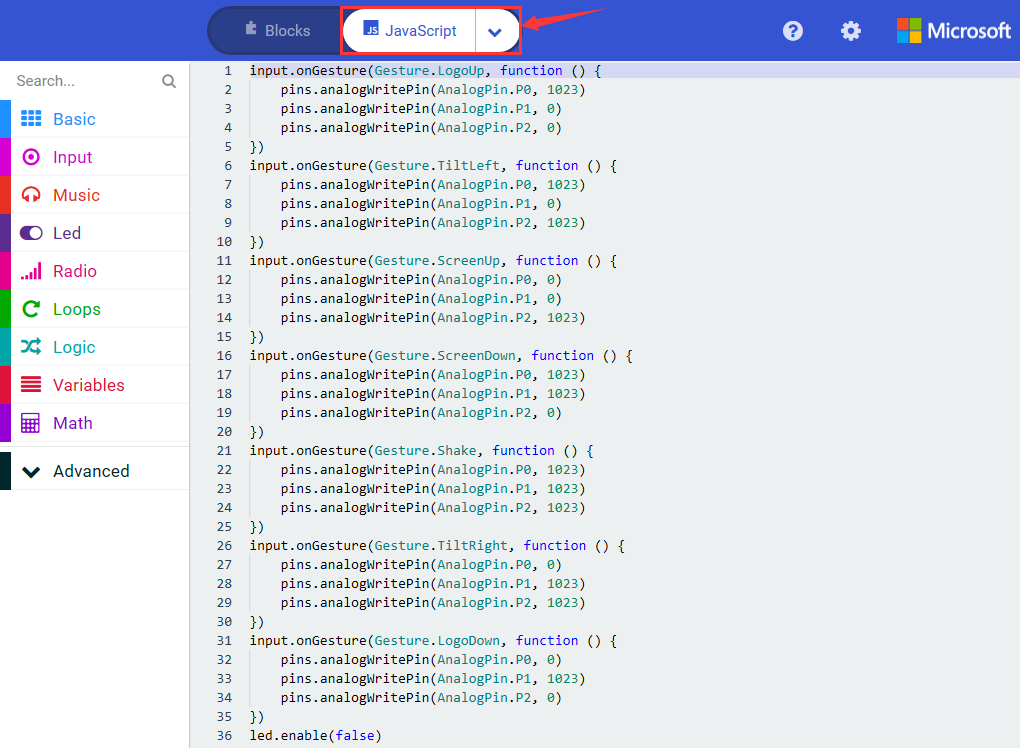

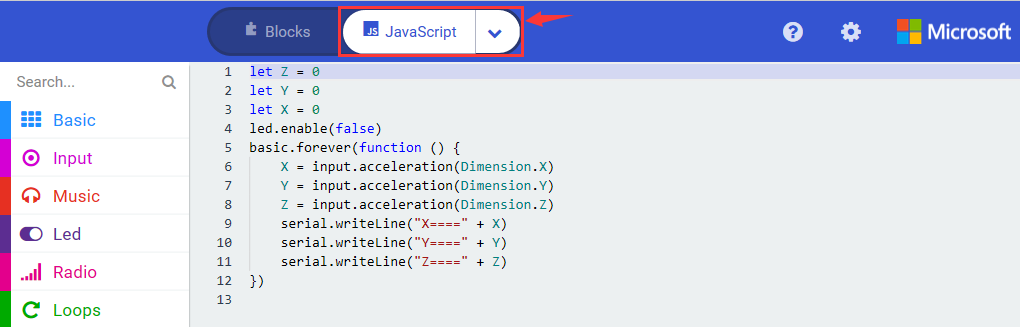

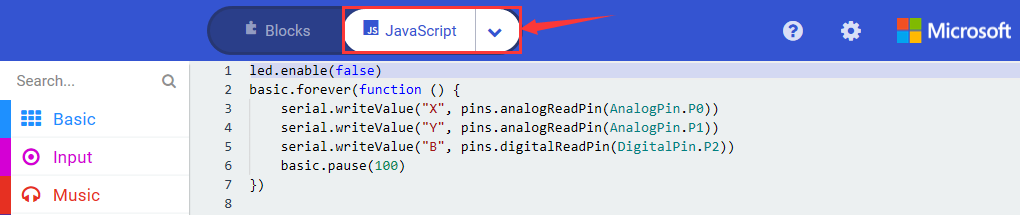

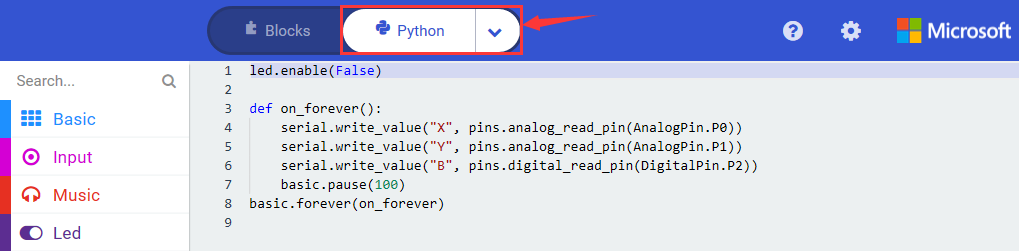

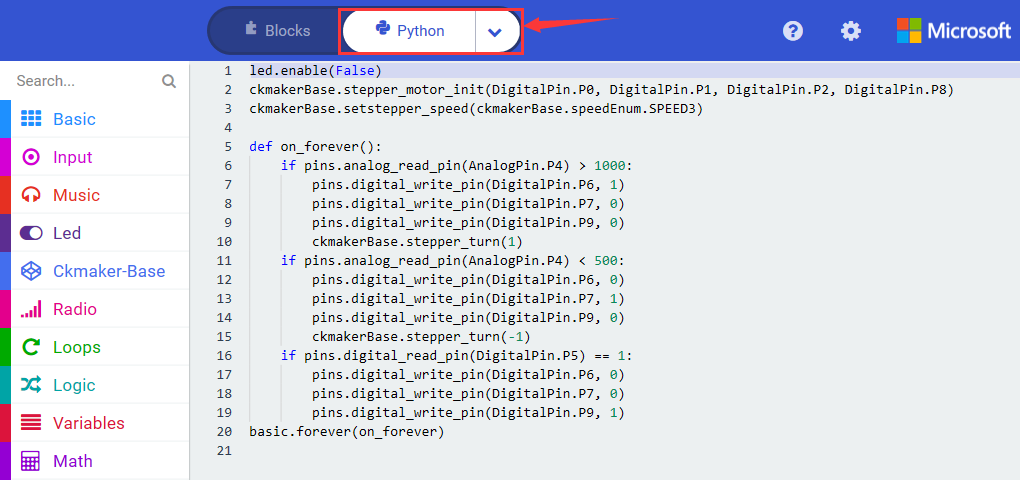

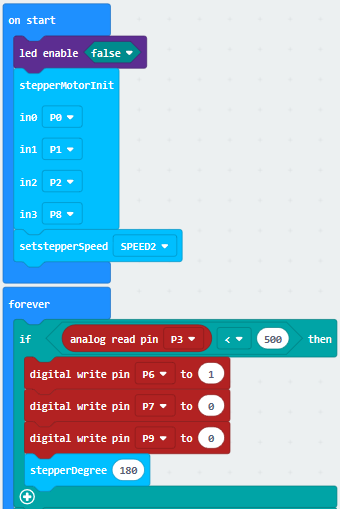

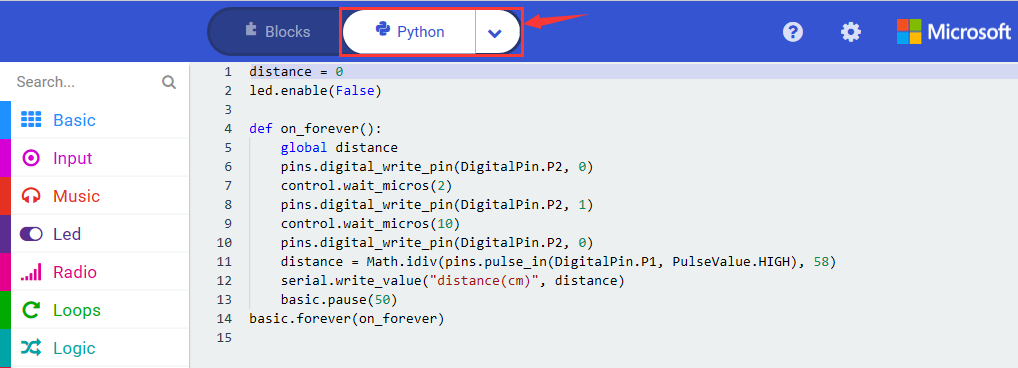

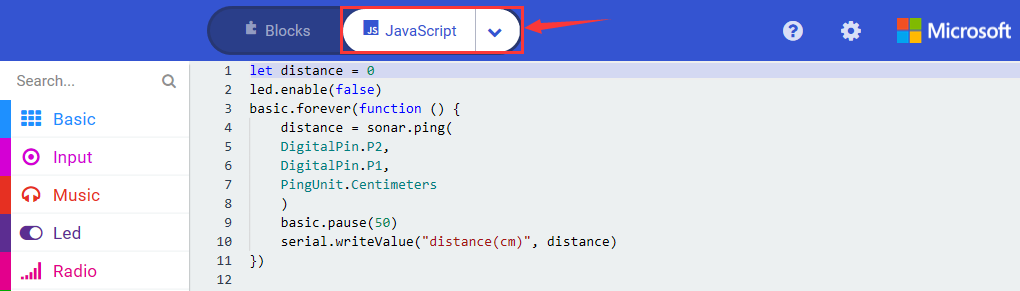

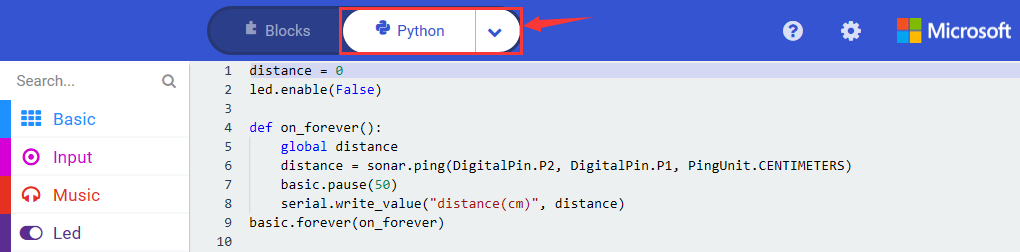

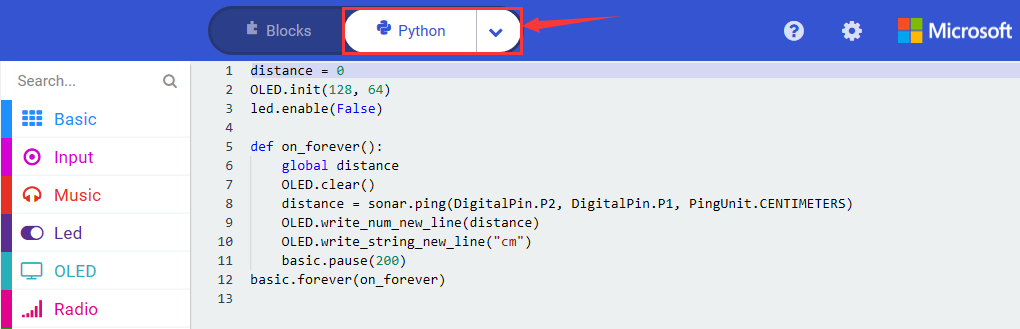

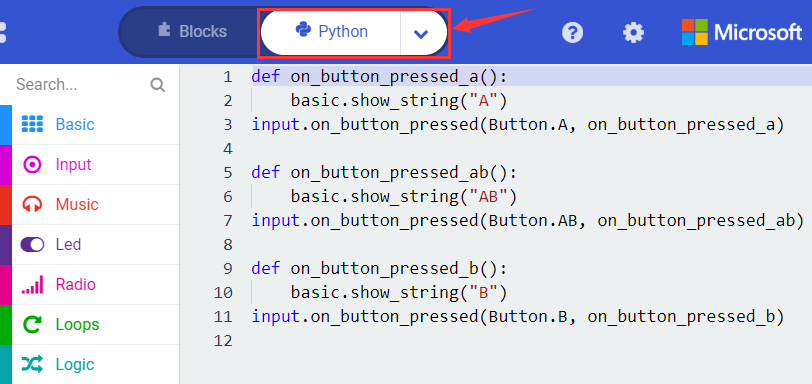

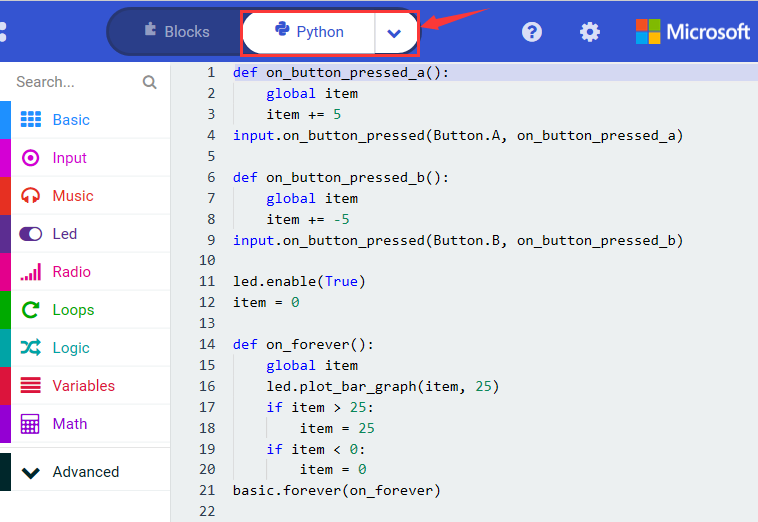

Click“JS JavaScript”, you will find the corresponding programming languages.

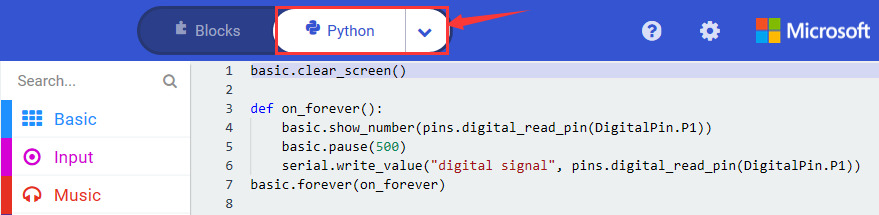

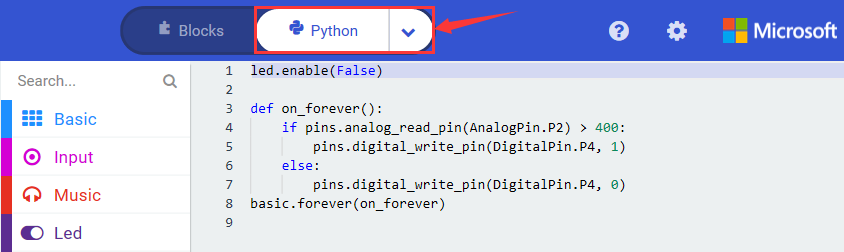

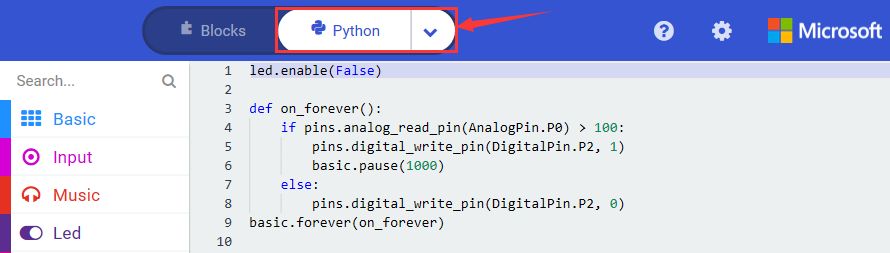

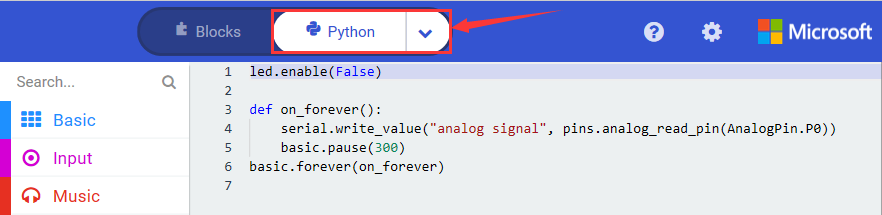

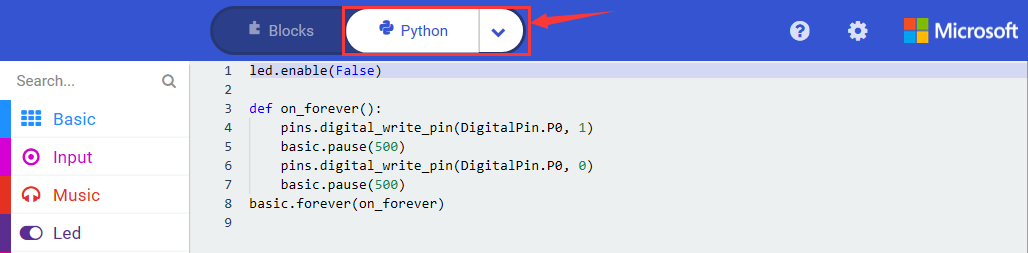

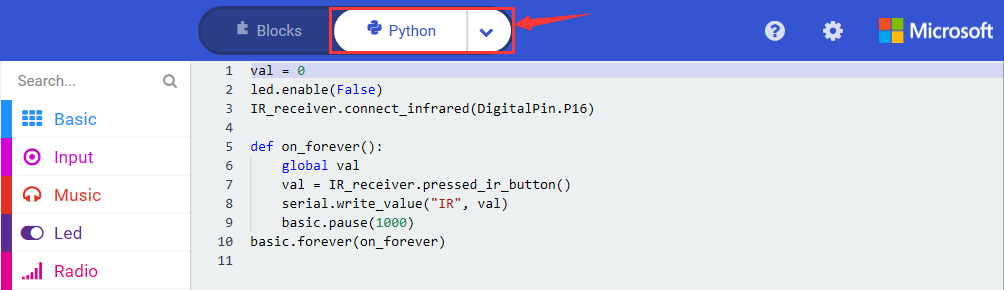

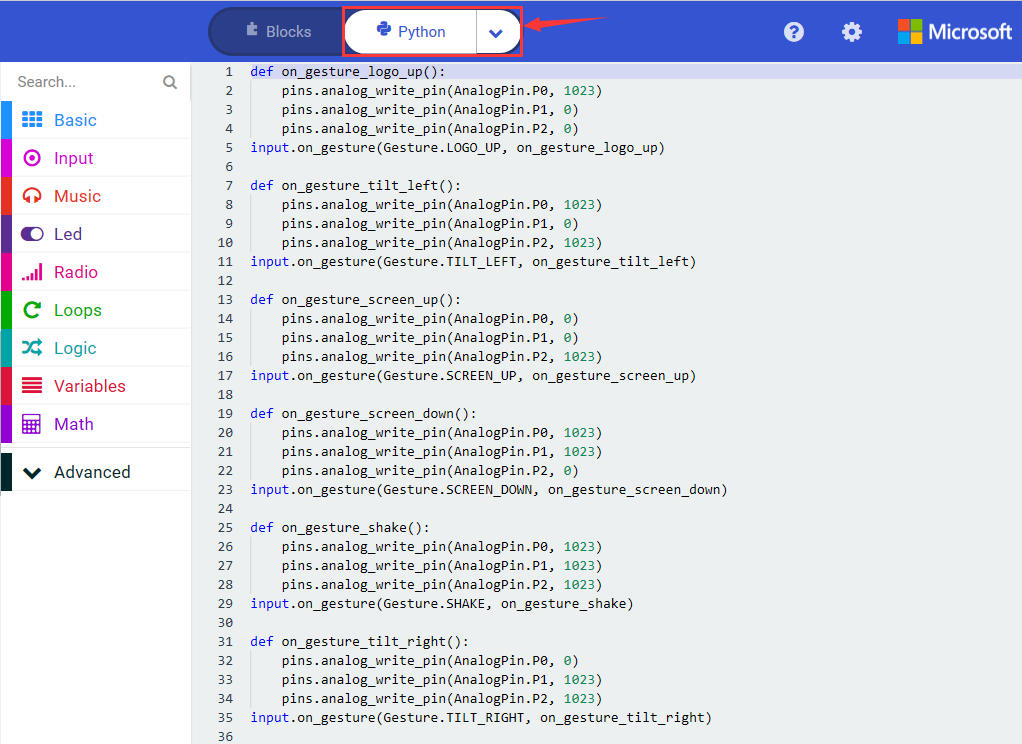

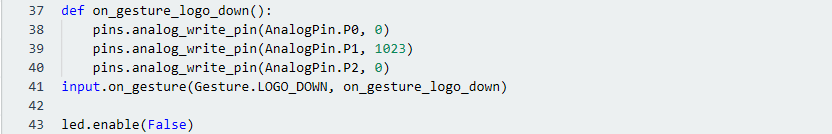

Click the little triangle”of JS JavaScript”to choose “Python”, you will find the corresponding Python programming languages.

( 4 )Test Results:

After uploading test code to micro:bit main board V2 and keeping the connection with the computer to power the main board, the LED dot matrix shows pattern “ ”and then“

”and then“ ”alternatively.

”alternatively.

( Please refer to chapter 5.3 to know how to download test code quickly.)

If the downloading is not smooth, please remove the micro USB from the main board and then reconnect them and reopen Makecode to try again.

Project 2: Light A Single LED

( 1 )Project Description:

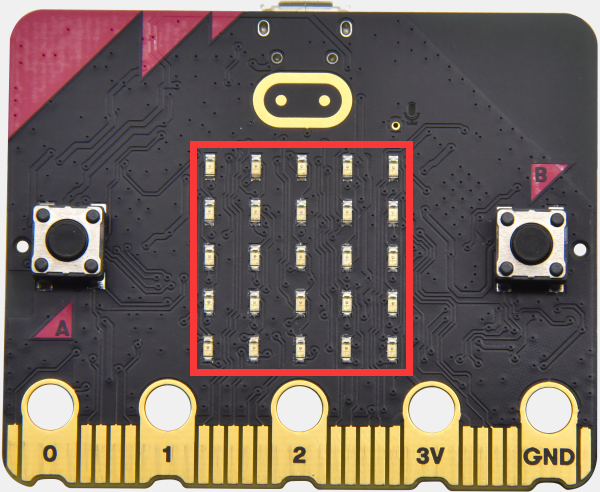

In this project, we intend to control a certain LED of the micro:bit main board V2 to shine.

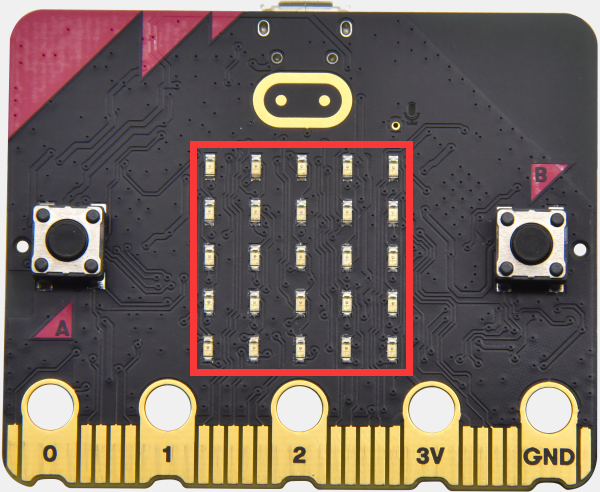

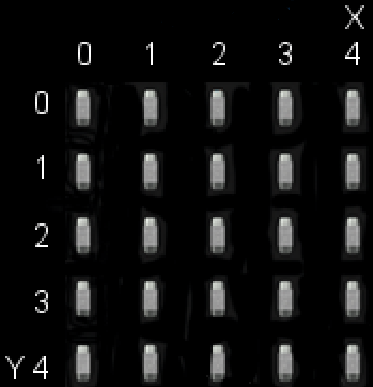

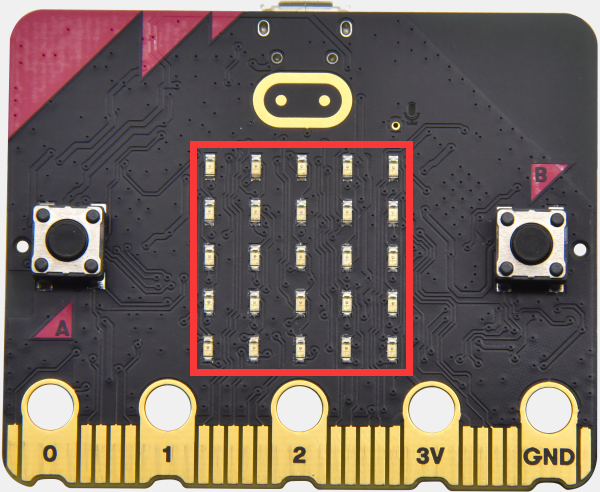

The LED dot matrix consists of 25 LEDs arranged in a 5 by 5 square. In order to locate these LEDs quickly, as the figure shown below, we can regarded this matrix as a coordinate system and create two aces by marking those in rows from 0 to 4 from top to bottom, and the ones in columns from 0 to 4 from the left to the right. Therefore, the LED sat in the second of the first line is (1,0)and the LED positioned in the fifth of the fourth column is (3,4)and others likewise.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3 )Test Code:

Attach the Micro:bit main board V2 to your computer via the Micro USB cable and begin editing.

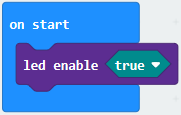

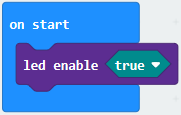

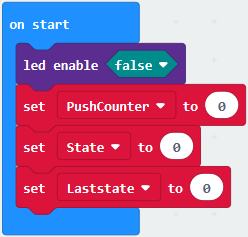

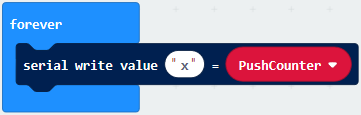

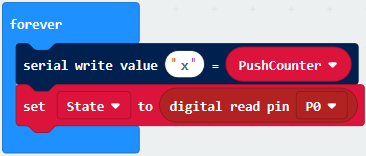

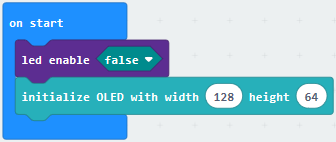

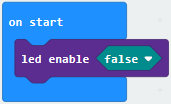

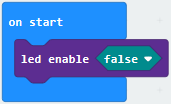

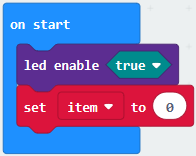

Firstly, click”Led”module and then the”more”module to find and drag the block “led enable false “ to block“on start”; click the little triangle of “led enable false “ to select”true”;

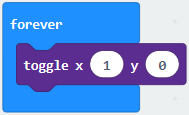

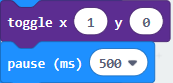

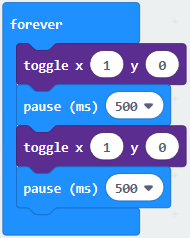

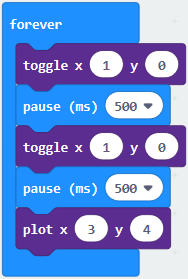

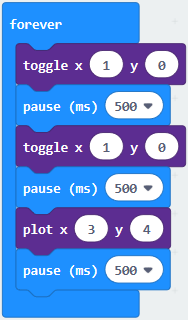

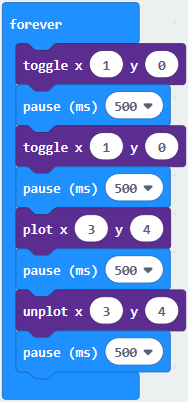

Secondly, click”Led”module and to find and drag the block “toggle x 0 y 0“ to block“forever”and alter “x0” to”x1”;

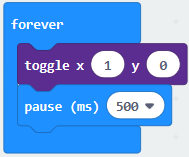

Thirdly, click”Basic”module to find and drag the block”pause(ms)100”to “forever” block and set pause to 500;

Fourthly, copy the block  and place it into forever” block;

and place it into forever” block;

Fifthly, click”Led”module to find and drag the block”plot x 0 y 0”to “forever” block and change the “x 0 y 0” to “x 3 y 4”;

Sixthly, copy the block“pause(ms)500”and place it into forever”block;

Lastly, click”Led”module to find and drag the block”unplot x 0 y 0”to “forever” block and change “x 0 y 0” to “x 3 y 4”;and copy and place the block“pause(ms)500”to block “forever”;

Complete Program:

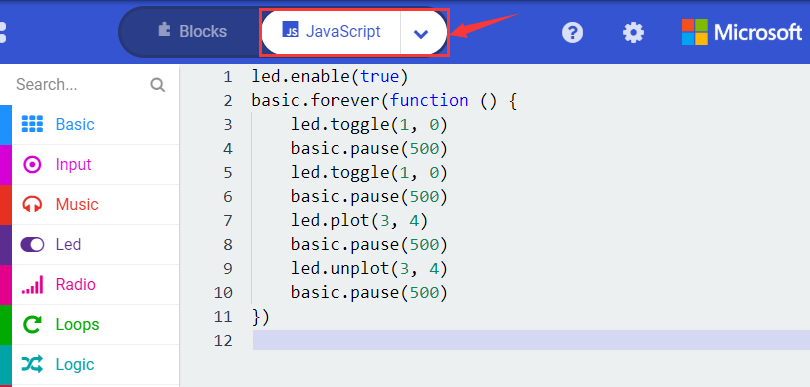

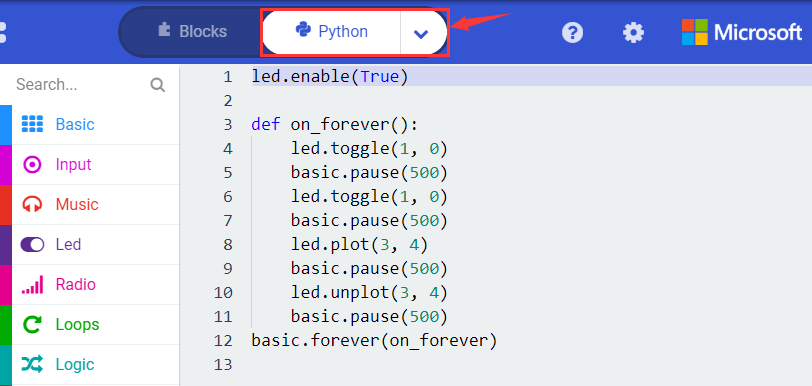

Click”JS JavaScript”, you will find the corresponding programming languages.

Click the little triangle”of JS JavaScript”to choose “Python”, you will find the corresponding Python programming languages.

( 4)Test Results

After uploading test code to micro:bit main board V2 and powering the main board via the USB cable, the LED in (1,0) lights up for 0.5s and the one in (3,4) shines for 0.5s and repeat this sequence.

Project 3: LED Dot Matrix

( 1 )Project Description:

Dot matrices are very commonplace in daily life. They have found wild applications in LED advertisement screens, elevator floor display, bus stop announcement and so on.

The LED dot matrix of Micro: Bit main board V2 contains 25 LEDs in a grid. Previously, we have succeeded in controlling a certain LED to light by integrating its position value into the test code. Supported by the same theory, we can turn on many LEDs at the same time to showcase patterns, digits and characters.

What’s more, we can also click”show icon“ to choose the pattern we like to display. Last but not the least, we can our design patterns by ourselves.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3 )Test Code 1:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

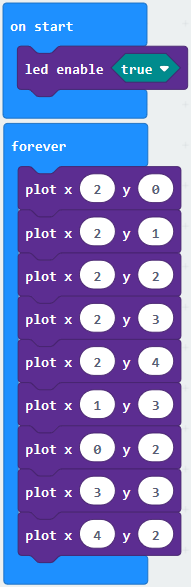

A. Enter“Led”→“more”→“led enable false”

Click the drop-down triangle button to select“true”

Combine it with “on start” block

*****************************************************************

Click“Led”to move“plot x 0 y 0”into“forever”,then replicate“plot x 0 y 0”for 8 times, respectively set to“x 2”y 0”,“x 2”y 1”,“x 2”y 2”,“x 2”y 3”,“x 2”y 4”,“x 1”y 3”“x 0”y 2”,“x 3”y 3”,“x 4”y 2”.

Complete Program:

|

“on start”: command block only runs once to start program. |

|---|---|

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results 1:

Upload code 1 and power on , we will see the  icon.

icon.

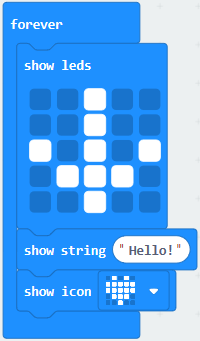

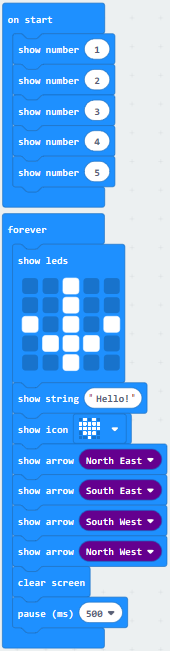

( 5 ) Test Code 2:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

A. Enter“Basic”→“show number 0”block,

Duplicate it for 4 times, then separately set to“show number 1”,“show number 2”,“show number 3”,“show number 4”,“show number 5”.

*****************************************************************

Click“Basic”→“show leds”, then put it into“forever”block,tick blue boxes to light LED and generate“↓”pattern.

*****************************************************************

Move out the block“show string” from“Basic”block, and leave it beneath the“show leds” block

Choose“show icon”from“Basic”block, and leave it beneath the block“show string“Hello!”block

*****************************************************************

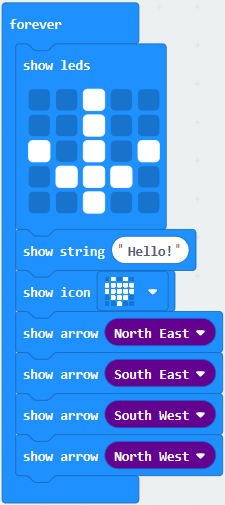

A. Enter“Basic”→“show arrow North”;

B. Leave it into“forever”block,replicate“show arrow North”for 3 times,respectively set to“North East”,“South East”, “South West”,“North West”.

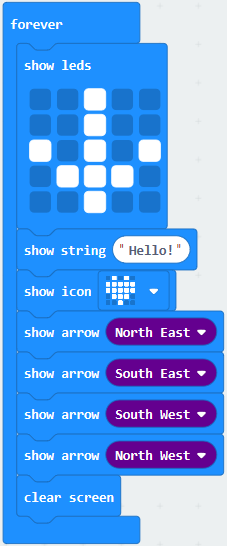

Click“Basic”to get block“clear screen”then remain it below the block “show arrow North West”。

*****************************************************************

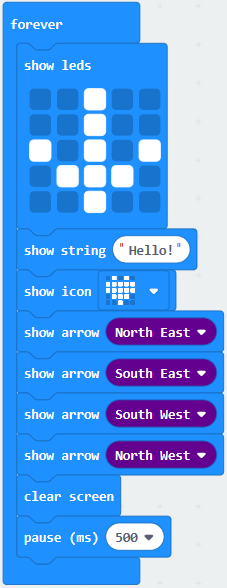

Drag“pause (ms) 100”block from“Basic”block and set to 500ms, then leave it below“clear screen”block.

Complete Program:

|

“on start”: command block only runs once to start program. |

|---|---|

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 6 )Test Results 2:

Upload code 2 and plug micro:bit to power. Micro: bit starts showing number 1, 2, 3, 4, and 5, then cyclically display ,“Hello!”,

,“Hello!”, ,

, ,

, ,

, and

and  patterns.

patterns.

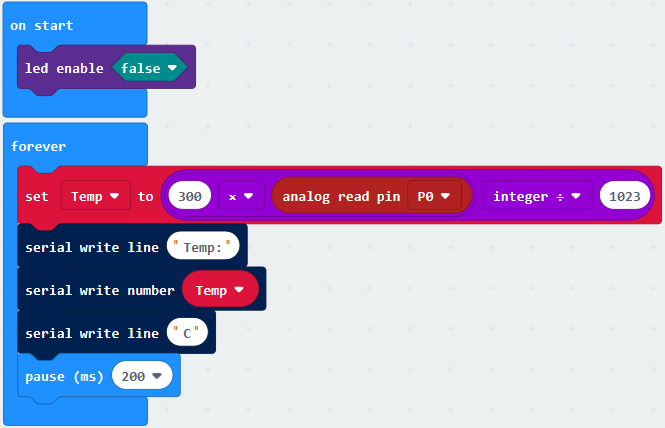

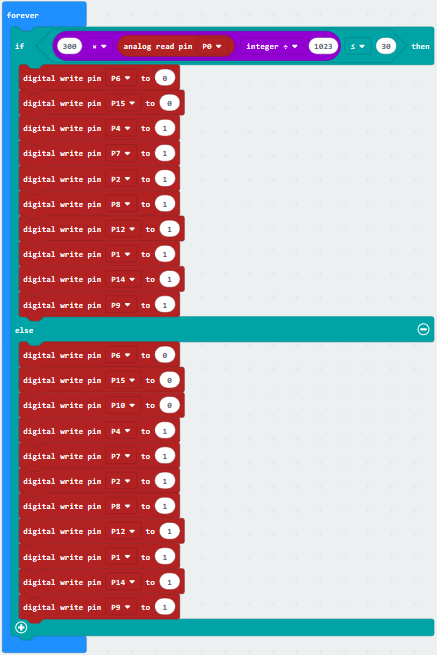

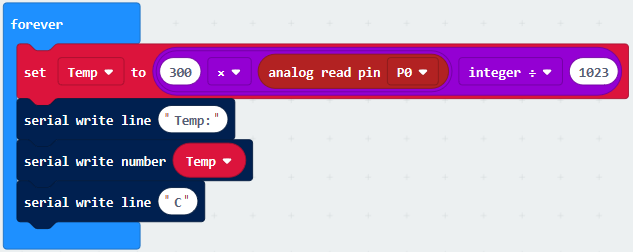

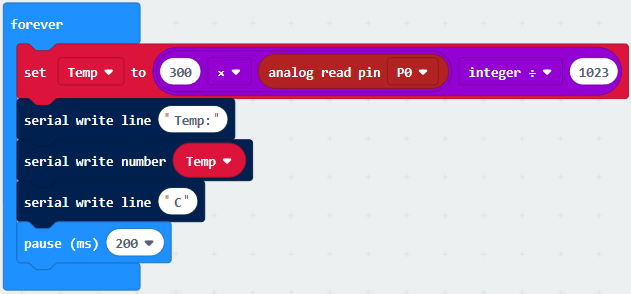

Project 5: Temperature Detection

( 1 )Project Description:

Actually ,the Micro:bit main board V2 is not equipped with a temperature sensor, but uses the temperature sensor built into NFR52833 chip for temperature detection. Therefore, the detected temperature is more closer to the temperature of the chip, and there maybe deviation from the ambient temperature.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*

( 3 )Test Code 1:

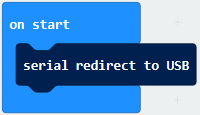

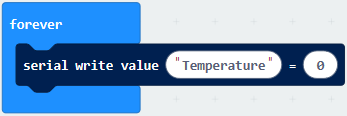

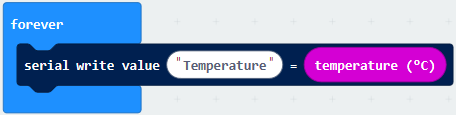

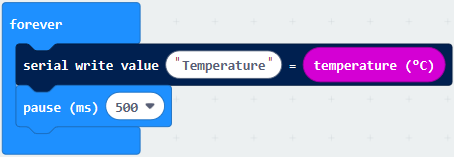

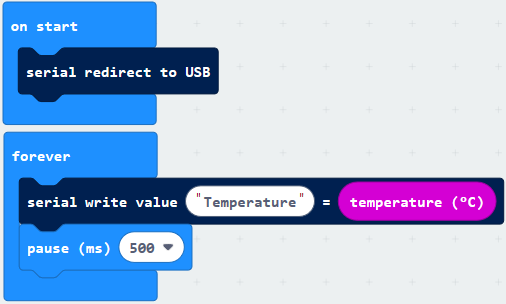

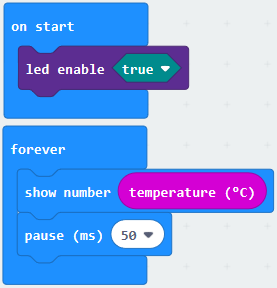

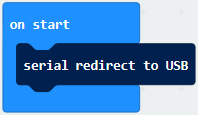

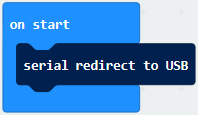

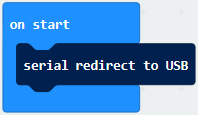

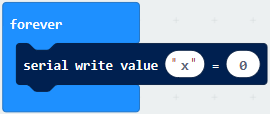

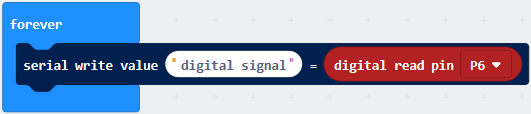

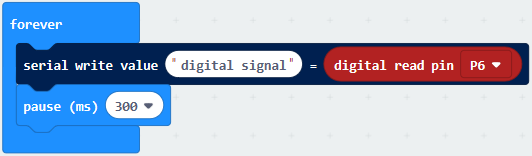

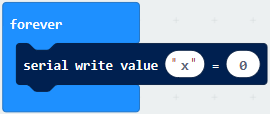

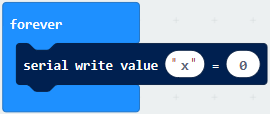

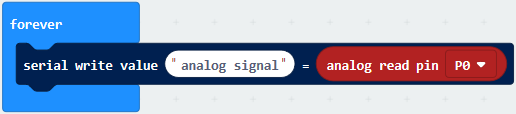

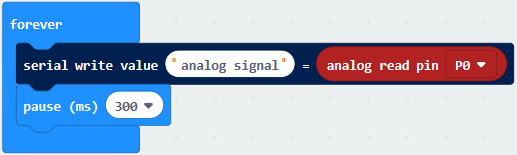

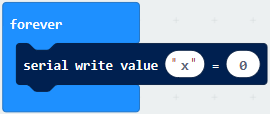

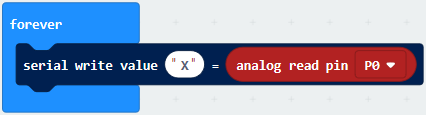

Click“Advanced”→”Serial”→“serial redirect to USB”into“on start”

*****************************************************************

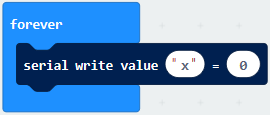

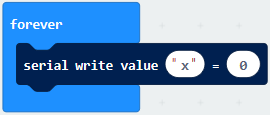

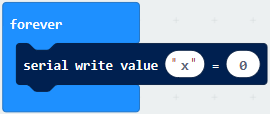

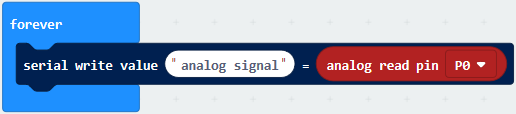

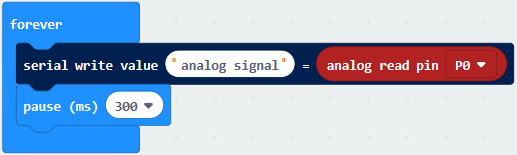

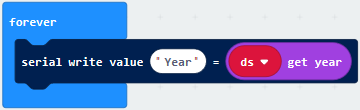

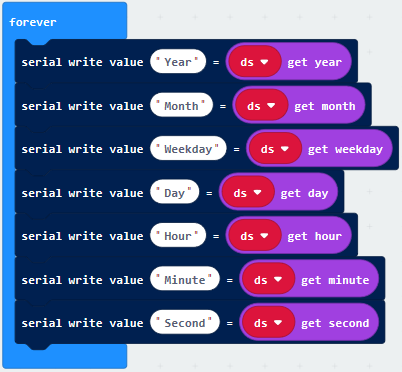

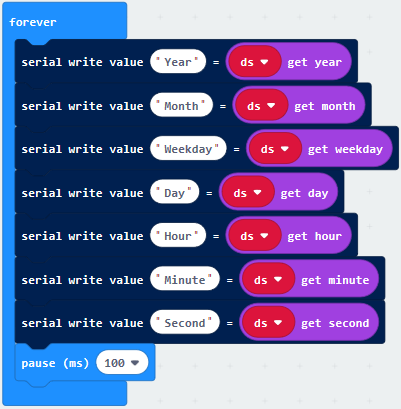

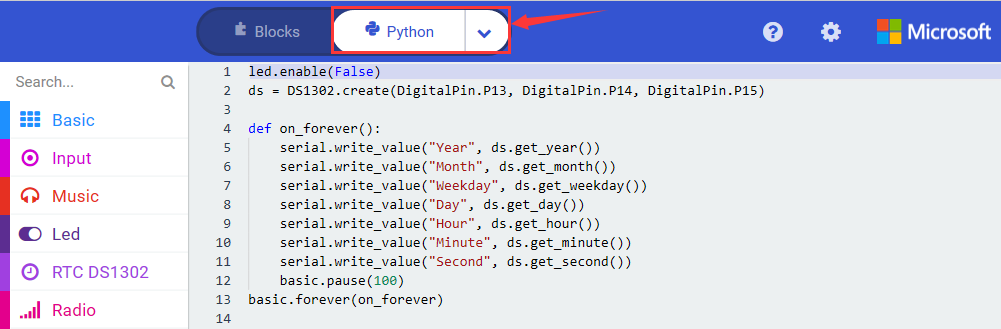

Go to“Serial”→“serial write value“x”=0”into “forever”

Click“Input” → “temperature(℃)” into“into serial write value“x”=0 and change”0”into “temperature”

*****************************************************************

Go to“Basic”→“pause (ms) 100”into “forever”and set pause to 500

*****************************************************************

Complete Program:

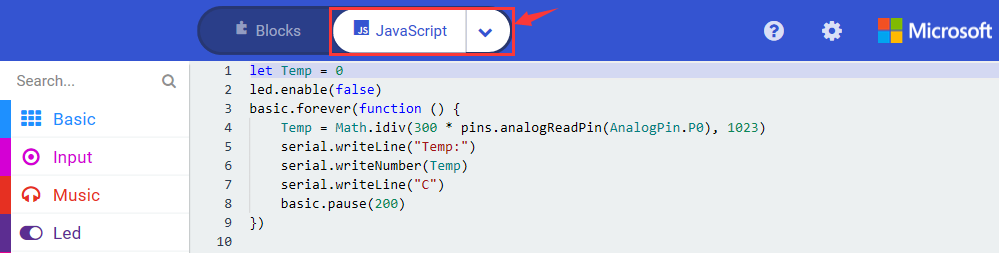

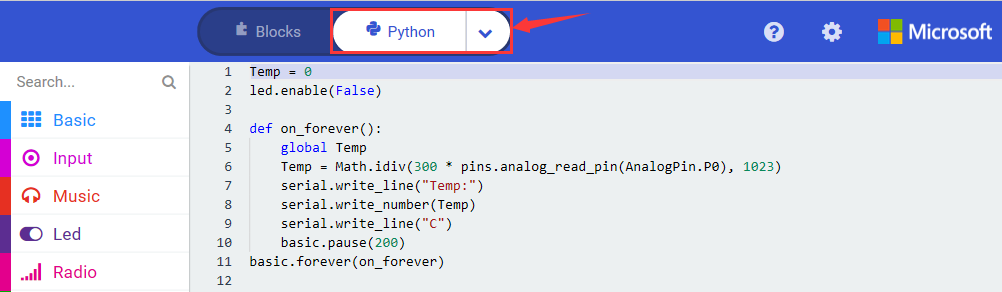

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results 1:

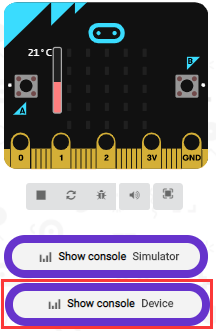

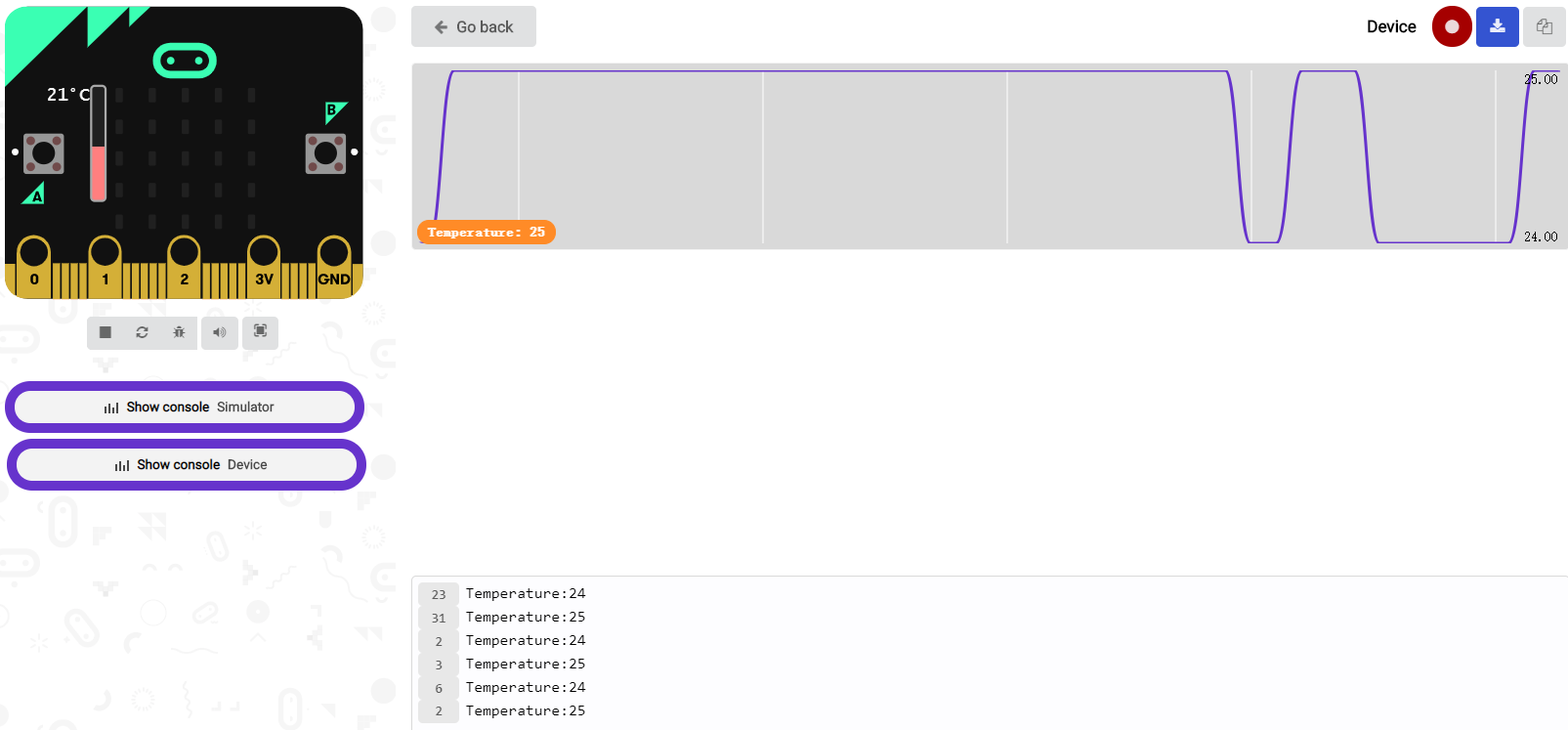

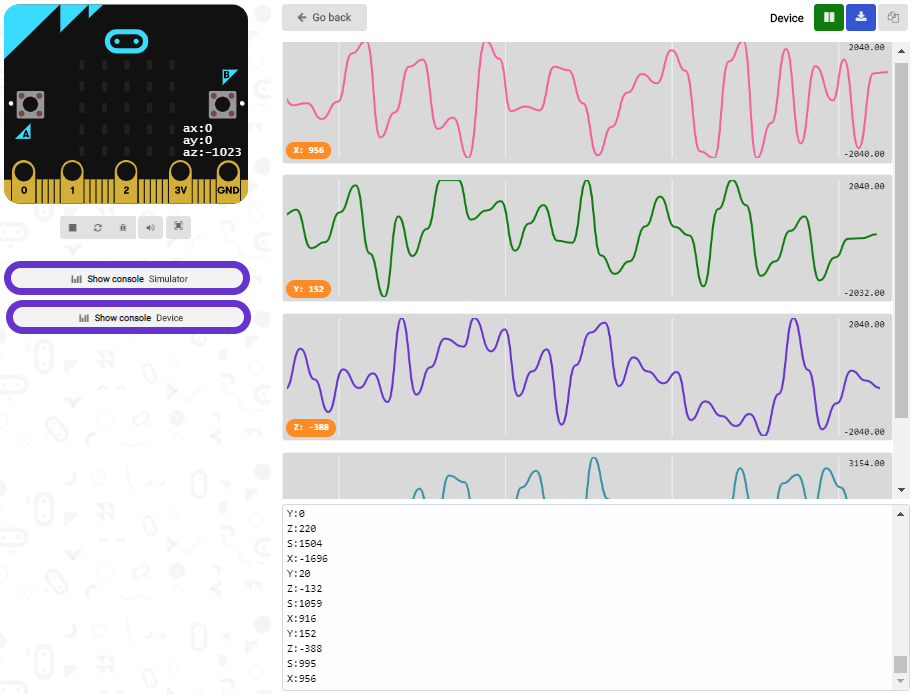

After uploading test code 1 to micro:bit main board V2, powering the main board via the USB cable, and clicking “Show console Device”, the data of temperature shows in the serial monitor page as shown below.

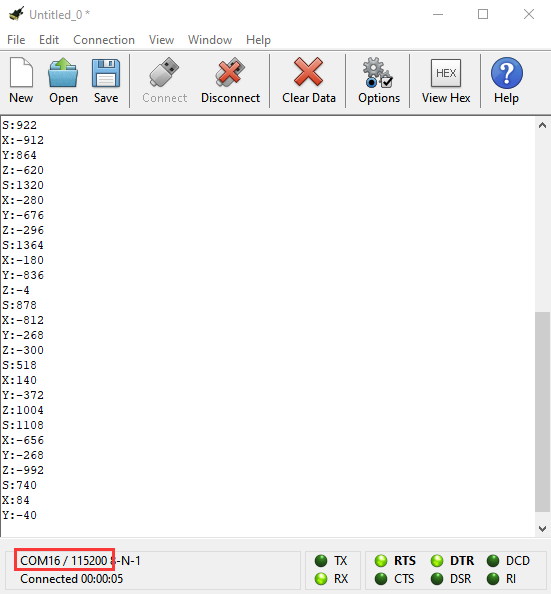

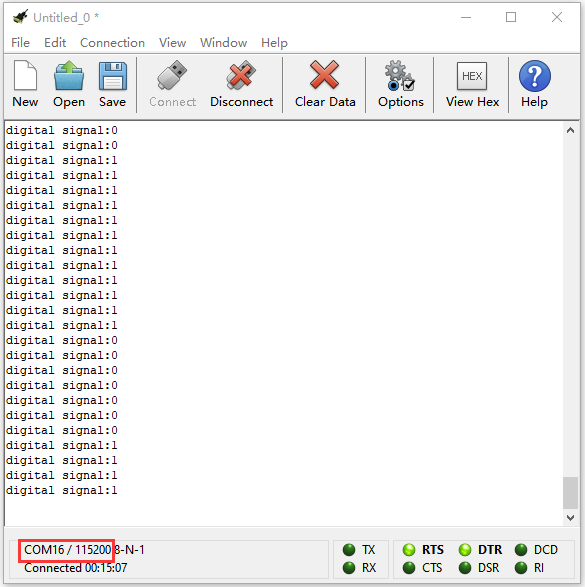

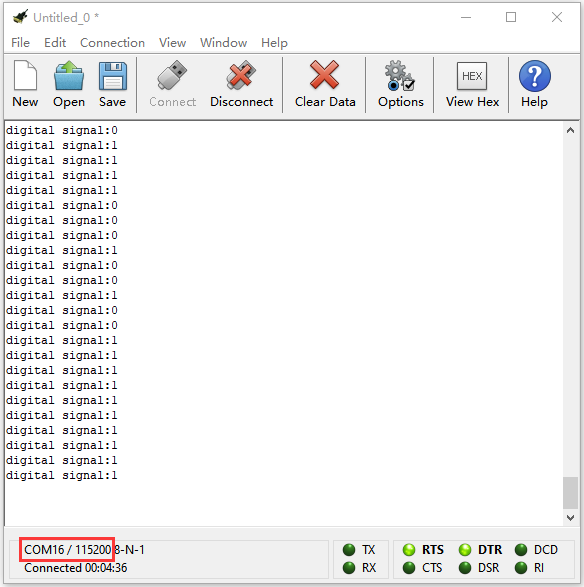

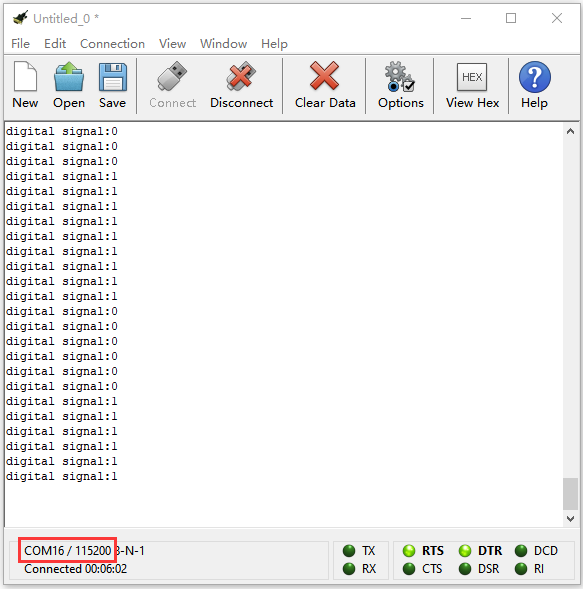

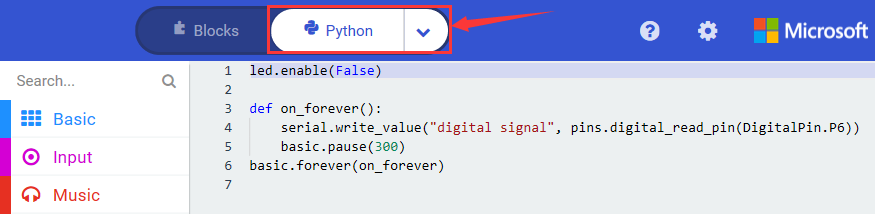

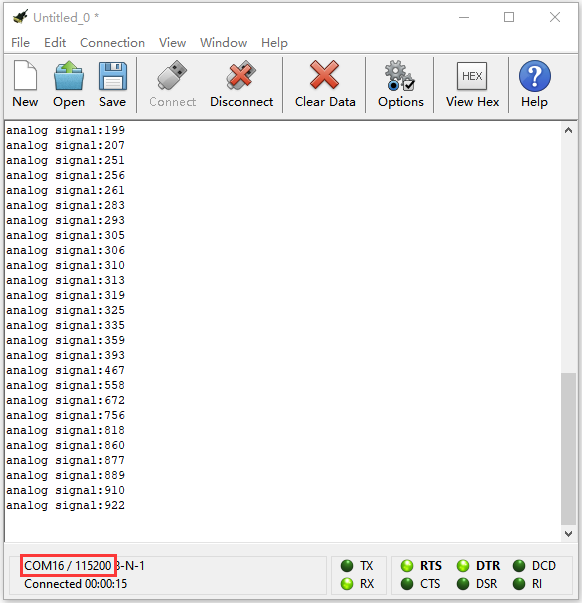

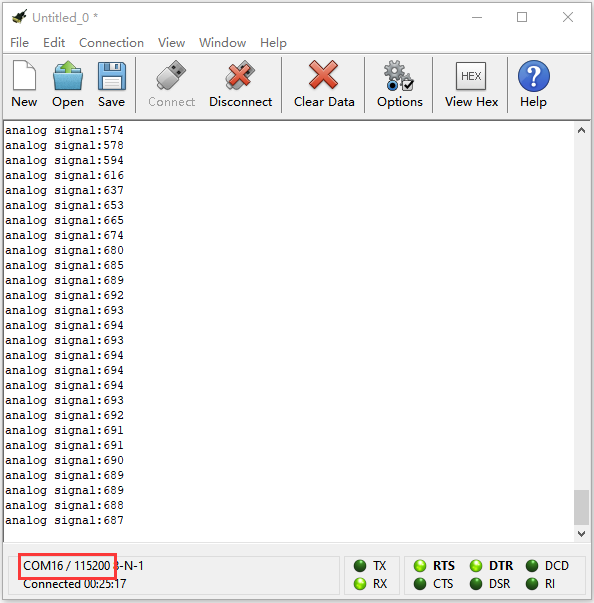

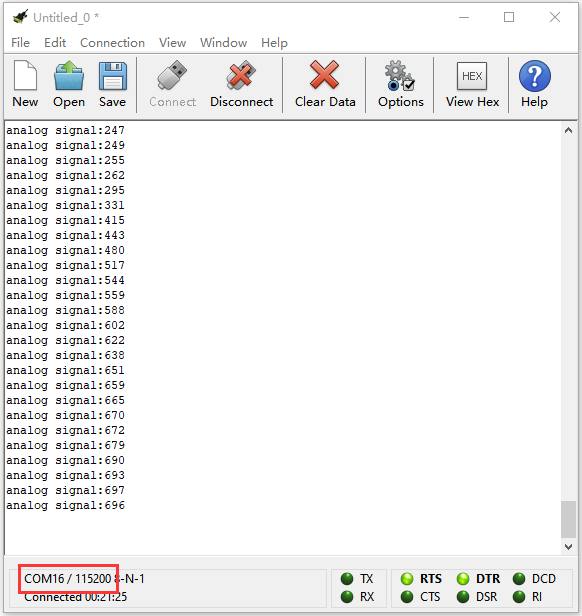

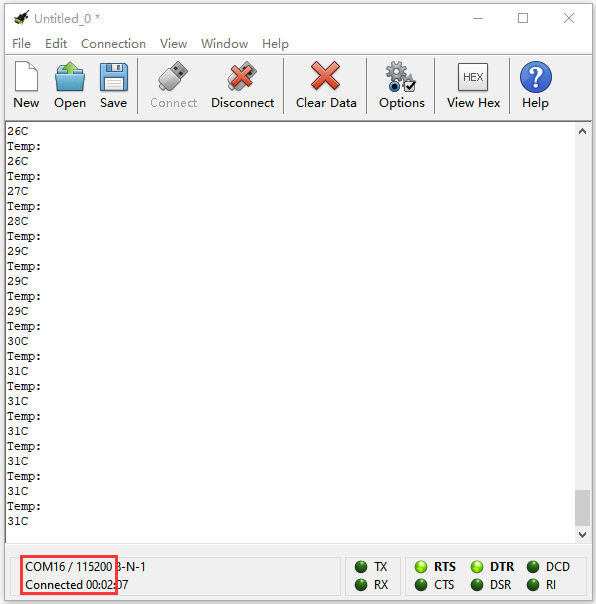

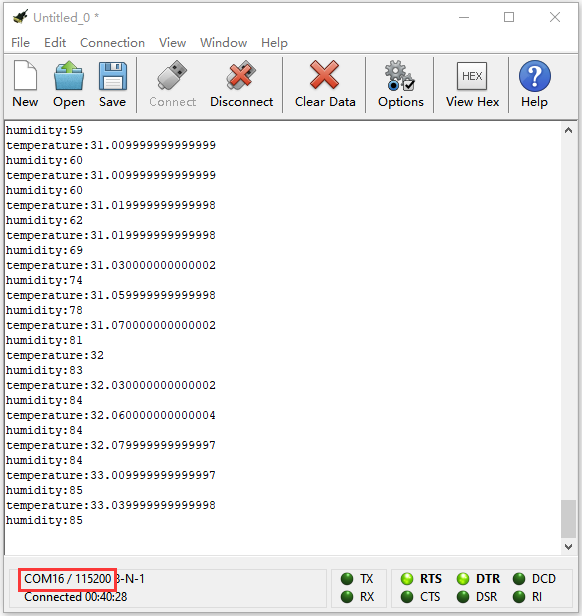

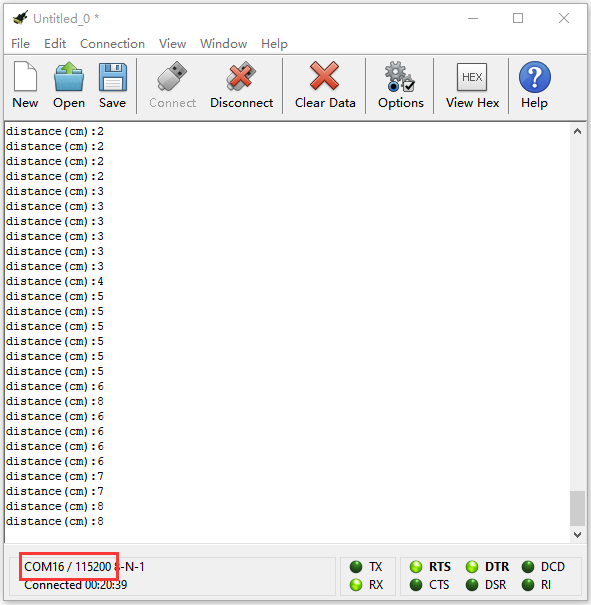

If you’re running Windows 7 or 8 instead of Windows 10, via Google Chrome won’t be able to match devices. You’ll need to use the CoolTerm serial monitor software to read data.

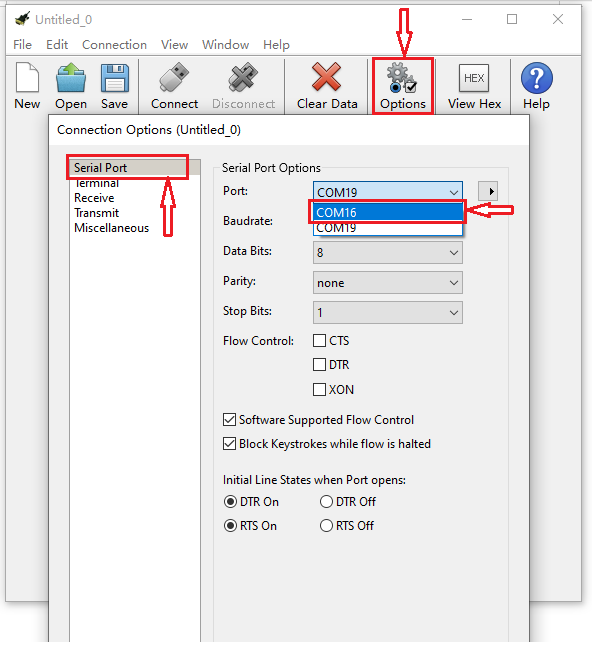

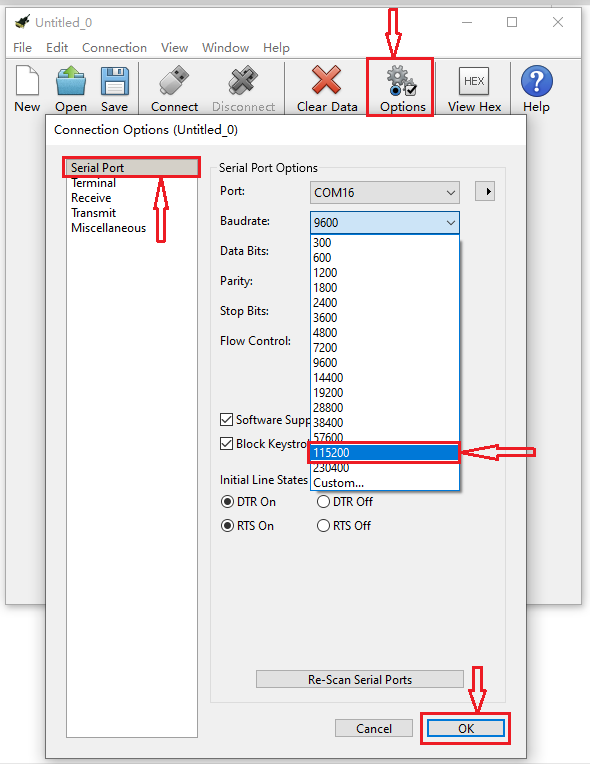

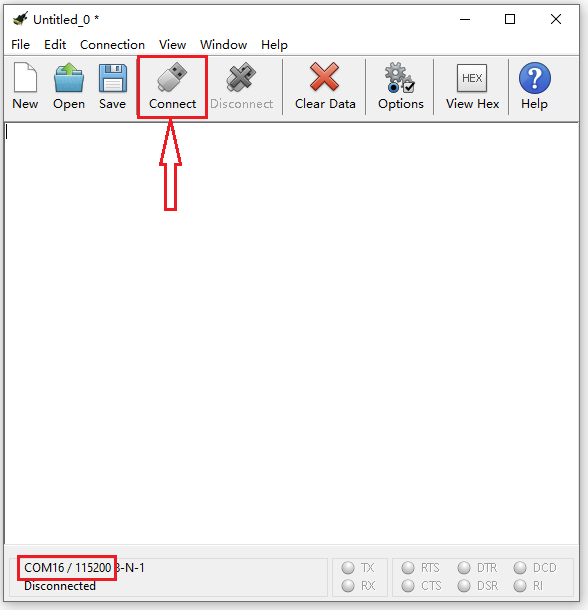

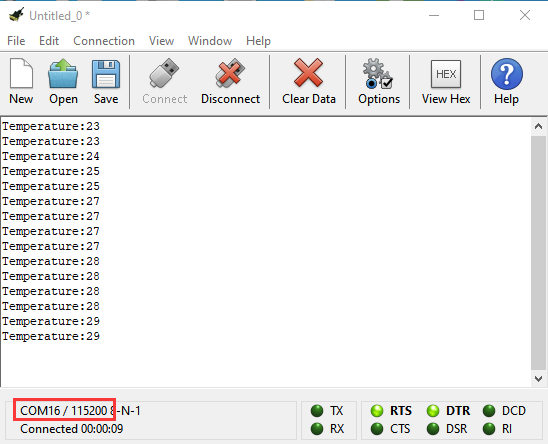

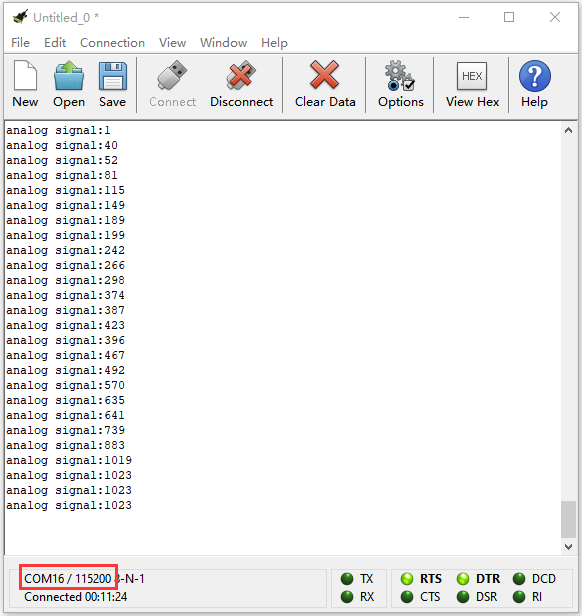

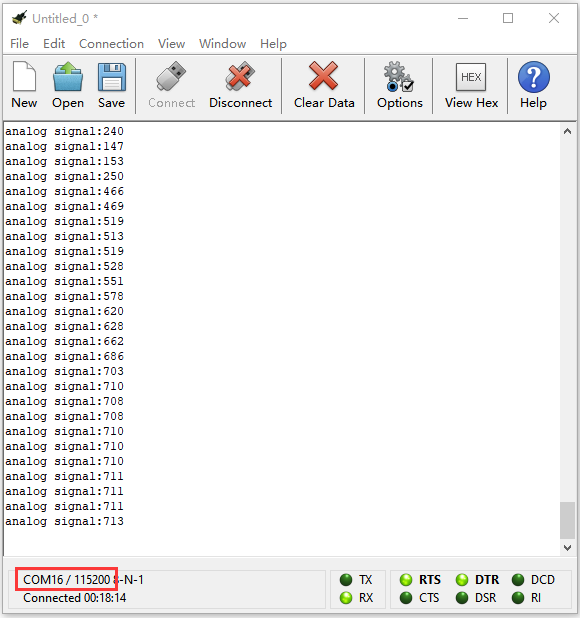

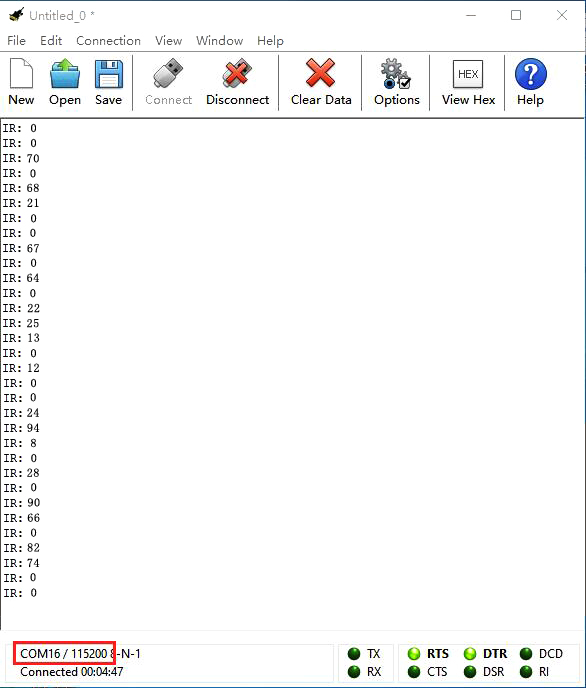

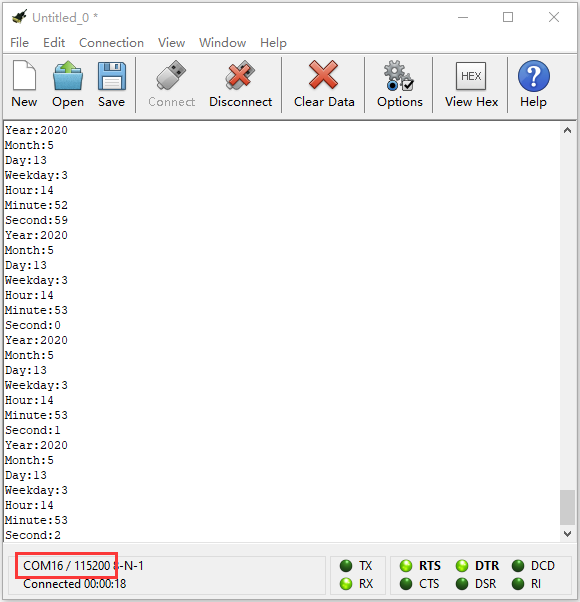

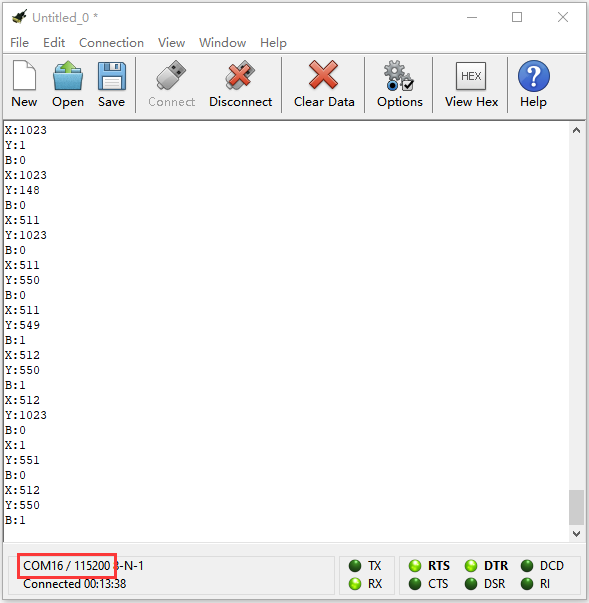

You could open CoolTerm software, click Options, select SerialPort, set COM port and baud rate to 115200 (after testing, the baud rate of USB SerialPort communication on Micro: Bit main board V2 is 115200), click OK, and Connect.

The CoolTerm serial monitor shows the change of temperature in the current environment, as shown in the figures below :

( 5 )Test Code 2:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

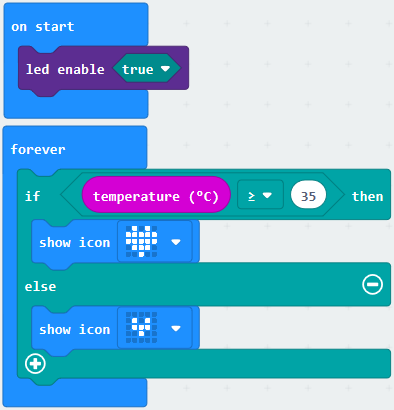

A. Go to“Led”→“more”→“led enable false”block,

B. Keep it into the“on start”block,tap the triangle button to select“true”.

*****************************************************************

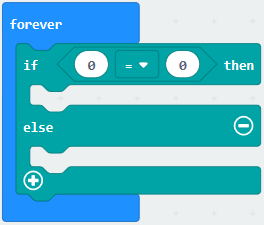

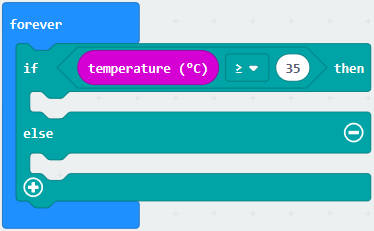

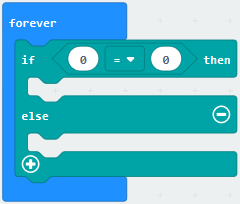

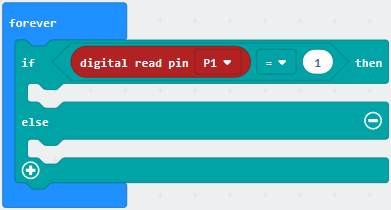

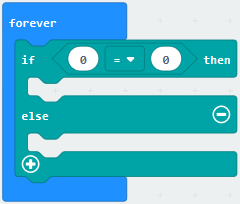

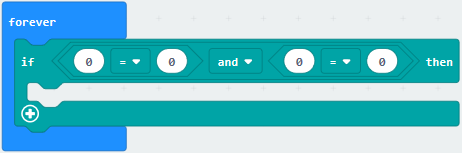

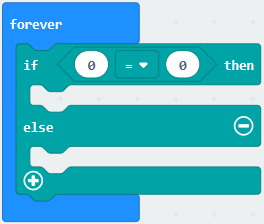

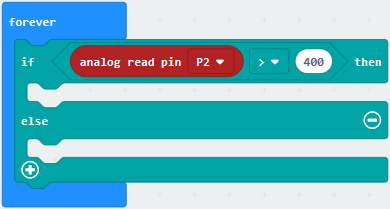

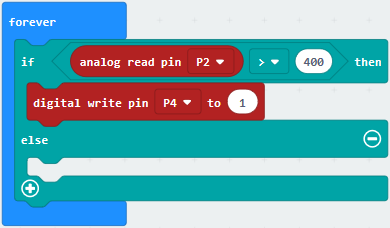

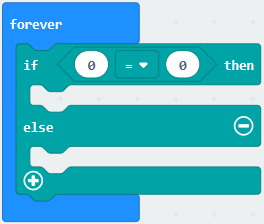

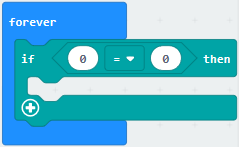

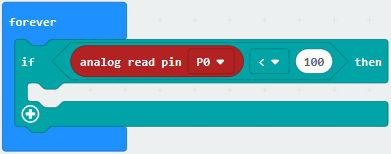

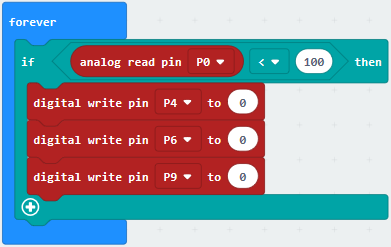

Tap“Logic”and drag“if…then…else”into“forever”block; and then drag “=” into “true”.

Enter“Input”to move“temperature(℃)”into the left side of “=”; click the little triangle of “=”to choose “≥”,and change the “0”to “35”

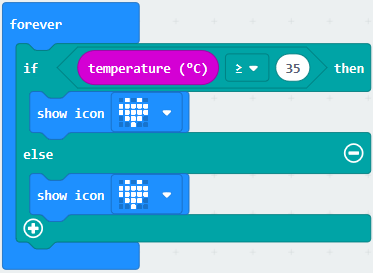

Click“Basic”to find out block“show icon”and move it into“then”; copy and place the block“show icon”to “else”and click the little triangle of “ ”to select“

”to select“ ”

”

Complete Program:

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

(6) Test Results 2:

After uploading the code 2, when the ambient temperature is less than 35℃, 5*5LED will show . When the temperature is equivalent to or greater than 35℃, the pattern

. When the temperature is equivalent to or greater than 35℃, the pattern will appear.

will appear.

Project 6: Geomagnetic Sensor

( 1 )Project Description:

This project aims to explain the use of the Micro: bit geomagnetic sensor, which can not only detect the strength of the geomagnetic field, but also be used as a compass to find bearings.

It is also an important part of the navigation attitude reference system (AHRS). Micro: Bit main board V2 uses LSM303AGR geomagnetic sensor, and the dynamic range of magnetic field is ±50 gauss. In the board, the magnetometer module is used in both magnetic detection and compass.

In this experiment, the compass will be introduced first, and then the original data of the magnetometer will be checked. The main component of a common compass is a magnetic needle, which can be rotated by the geomagnetic field and point toward the geomagnetic North Pole (which is near the geographic South Pole) to determine direction.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

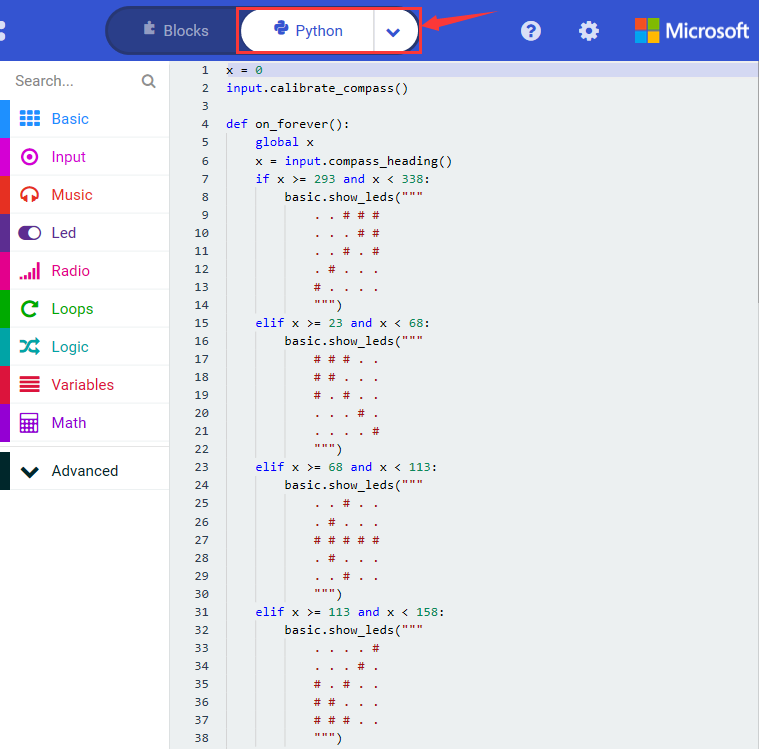

( 3 )Test Code 1:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

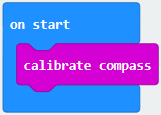

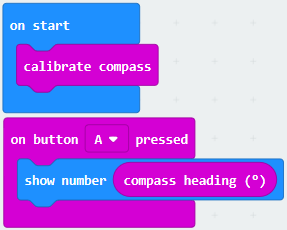

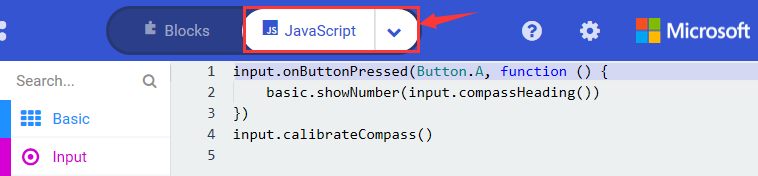

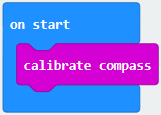

A. Click“Input”→“more”→“calibrate compass”

B. Lay down it into block“on start”.

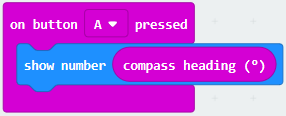

A. Go to“Input”→“on button A pressed”.

B. Enter“Basic”→“show number”, put it into“on button A pressed”block;

C. Tap“Input”→“compass heading(℃)”, and place it into“show number”

*****************************************************************

Complete Program:

|

①“on start”: command block only runs once to start program. |

|---|---|

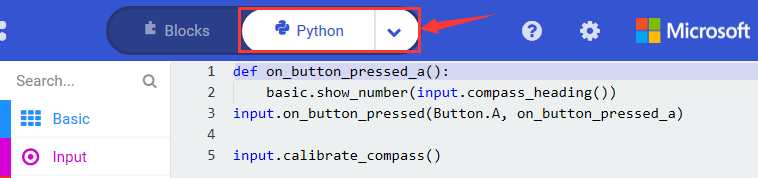

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results 1:

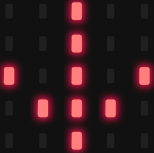

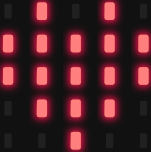

After uploading test code to micro:bit main board V2 and powering the board via the USB cable, and pressing the button A, the board asks us to calibrate compass and the LED dot matrix shows “TILT TO FILL SCREEN”. Then enter the calibration page. Rotate the board until all 25 LEDs are on red as shown below.

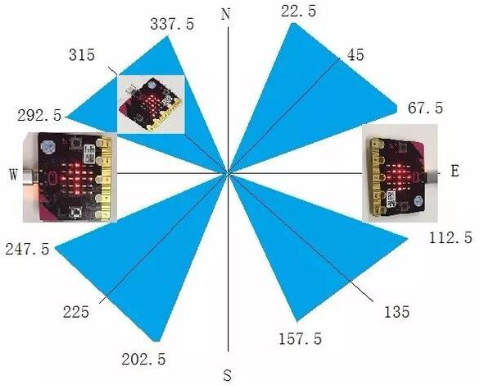

After that, a smile pattern  appears, which implies the calibration is done. When the calibration process is completed, pressing the button A will make the magnetometer reading display directly on the screen. And the direction north, east, south and west correspond to 0°, 90°, 180° and 270°.

appears, which implies the calibration is done. When the calibration process is completed, pressing the button A will make the magnetometer reading display directly on the screen. And the direction north, east, south and west correspond to 0°, 90°, 180° and 270°.

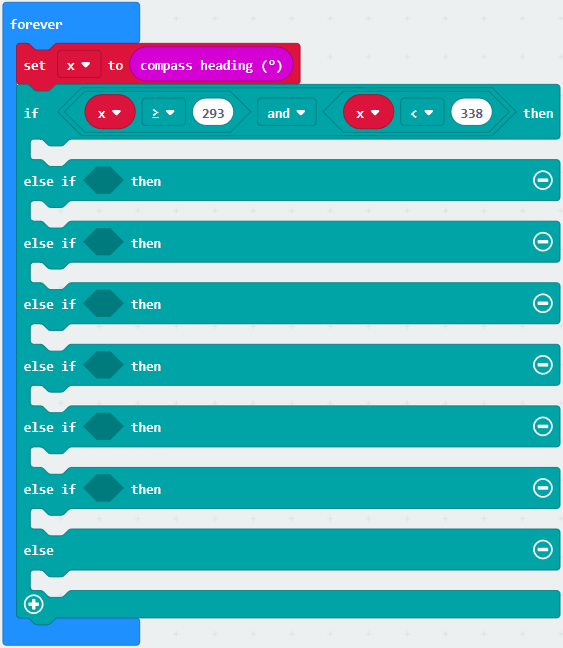

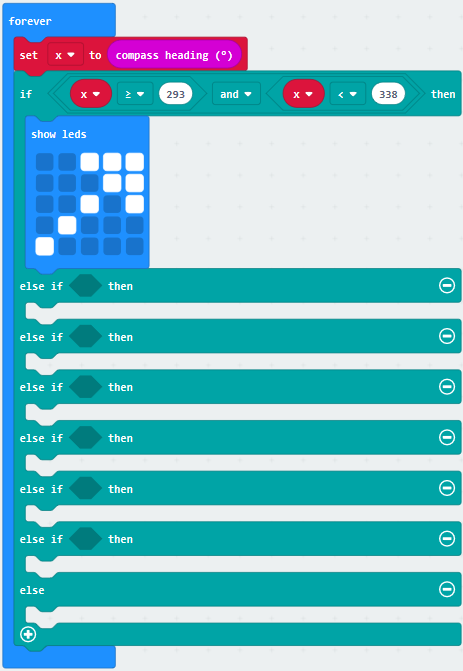

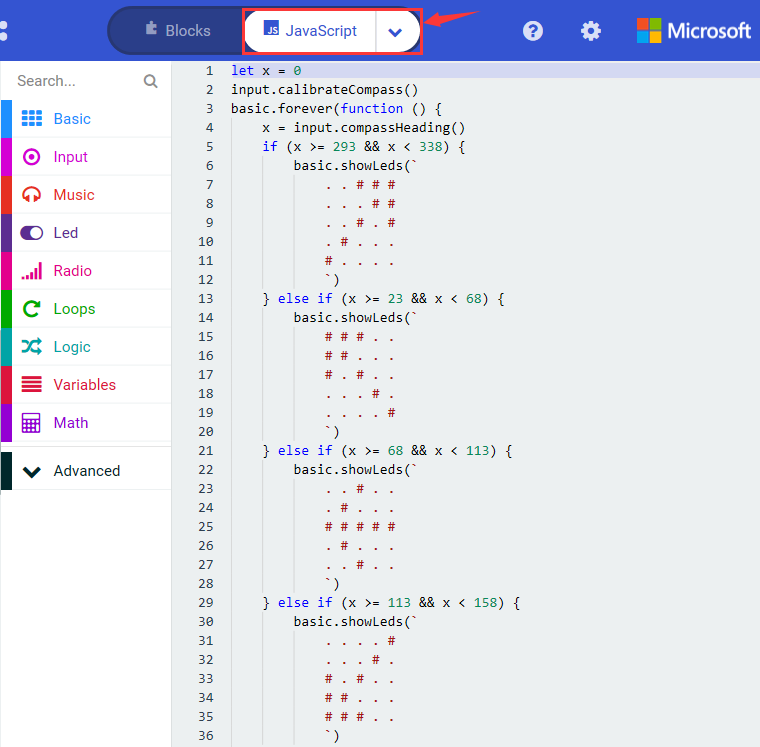

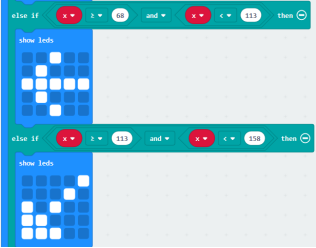

( 5 ) Test Code 2:

This module can keep readings to determine direction, so does point to the current magnetic North Pole by arrow.

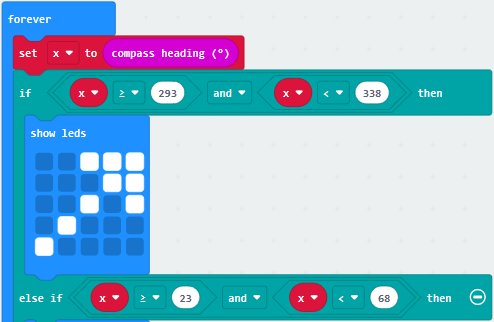

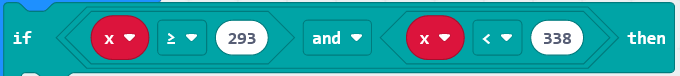

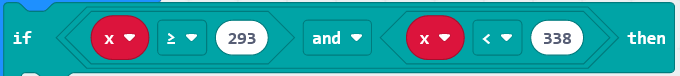

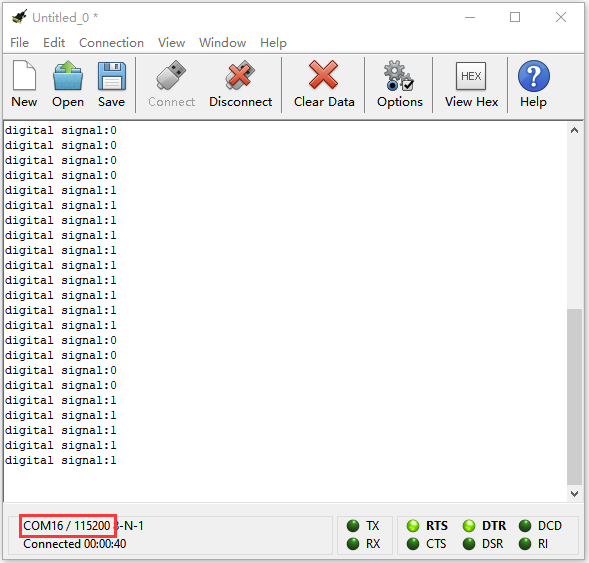

For the above picture, the arrow pointing to the upper right when the value ranges from 292.5 to 337.5. 0.5 can’t be input in the code, thereby, the values we get are 293 and 338.

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

Enter“Input”→ “more”→“calibrate compass”

Move“calibrate compass”into“on start”

*****************************************************************

A. Click“Variables”→“Make a Variable…”→“New variable name:”

B. Input“x”in the blank box and click“OK”, and the variable “x” is generated.

C. Drag out“set x to”into“forever”block

A. Go to“Input”→“compass heading(℃)”, and keep it into“0”box

Tap“Logic”→“if…then…else”, leave it below block“sex x to compass heading”, then click icon for 6 times.

icon for 6 times.

*****************************************************************

A. Place“and”into“true”block

B. Then move“=”block to the left box of “and”

C. Click“Variables”to drag“x”to the left “0”box, change 0 into 293 and set to “≥”;

D. Then copy“x≥293”once and leave it to the right “0”box and set to“x<338”

*****************************************************************

A. Go to“Basic”→“show leds”

B. Lay it down beneath  block, then click“show leds”and the pattern

block, then click“show leds”and the pattern appears.

appears.

A. Duplicate  for 6 times.

for 6 times.

B. Separately leave them into the blank boxes behind “else if”.

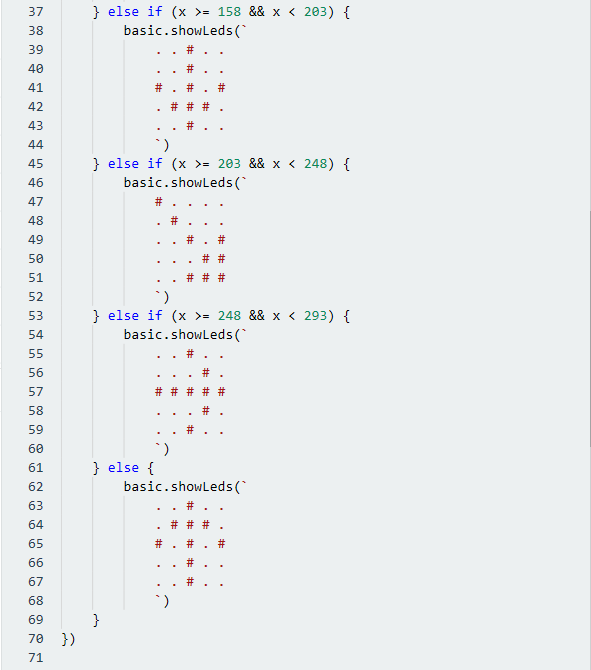

C. Set to“x≥23 and x<68”,“x≥68 and x<113 ”,“x≥113 and x<158 ”,“x≥158 and x<203 ”,“x≥203 and x<248 ”,“x≥248 and x<293 ”respectively.

D. Then copy “show leds”for 7 times and keep them below the “else if…then” block respectively.

E. Click the blue boxes to form the pattern“ ”, “

”, “ ”, “

”, “ ”, “

”, “ ”, “

”, “ ”, “

”, “ ”and “

”and “ ”.

”.

*****************************************************************

Complete Program:

|

“on start”: command block only runs once to start program. |

|---|---|

Select “JavaScript” and “Python” to switch into JavaScript and Python language code:

( 6 ) Test Results 2

Upload code 2 and plug micro:bit to power. After calibration, tilt micro:bit board, the LED dot matrix displays the direction signs.

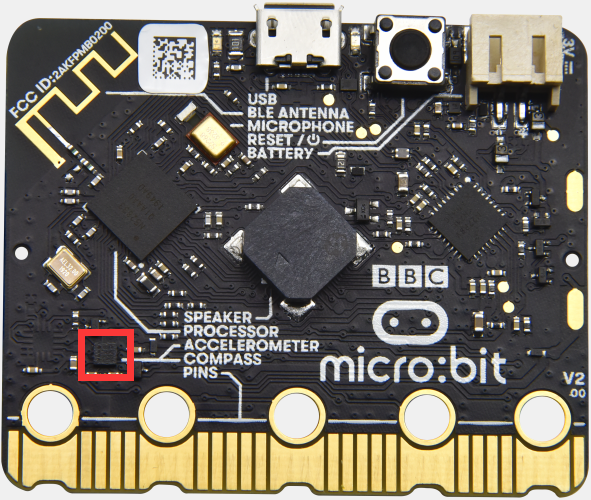

Project 7: Accelerometer

( 1 )Project Description:

The Micro: Bit main board V2 has a built-in LSM303AGR gravity acceleration sensor, also known as accelerometer, with a resolution of 8/10/12 bits. The code section sets the range to 1g, 2g, 4g, and 8g.

We often use accelerometer to detect the status of machines.

In this project, we will introduce how to measure the position of the board with the accelerometer. And then have a look at the original three-axis data output by the accelerometer.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3 )Test Code 1:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor,

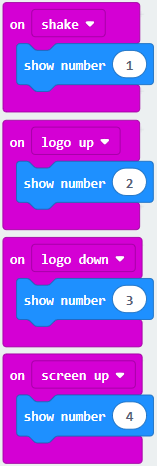

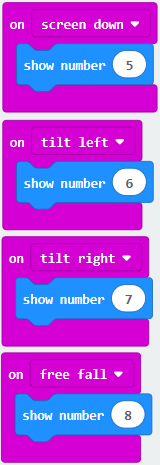

(1) A. Enter“Input”→“on shake”,

B. Click“Basic”→“show number”, place it into“on shake”block, then change 0 into 1.

*****************************************************************

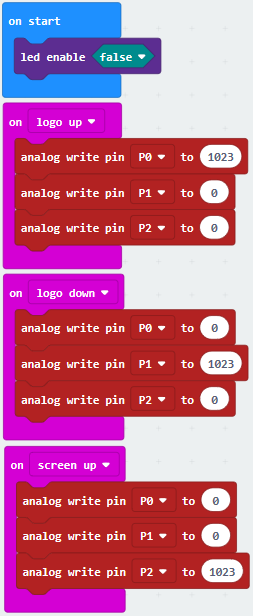

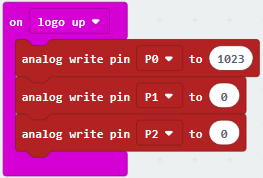

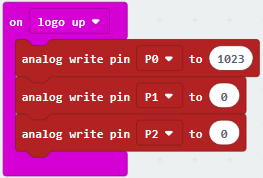

(2) A. Copy code string  for 7 times; separately click the triangle button to select“logo up”,“logo down”,“screen

up”,“screen down”,“tilt left”,“tilt right”and“free fall”, then respectively change 1 into 2, 3, 4, 5, 6, 7, 8.

for 7 times; separately click the triangle button to select“logo up”,“logo down”,“screen

up”,“screen down”,“tilt left”,“tilt right”and“free fall”, then respectively change 1 into 2, 3, 4, 5, 6, 7, 8.

*****************************************************************

Complete Program:

|

Shake the Micro:bit board |

|---|---|

Select “JavaScript” and “Python” to switch into JavaScript and Python language code:

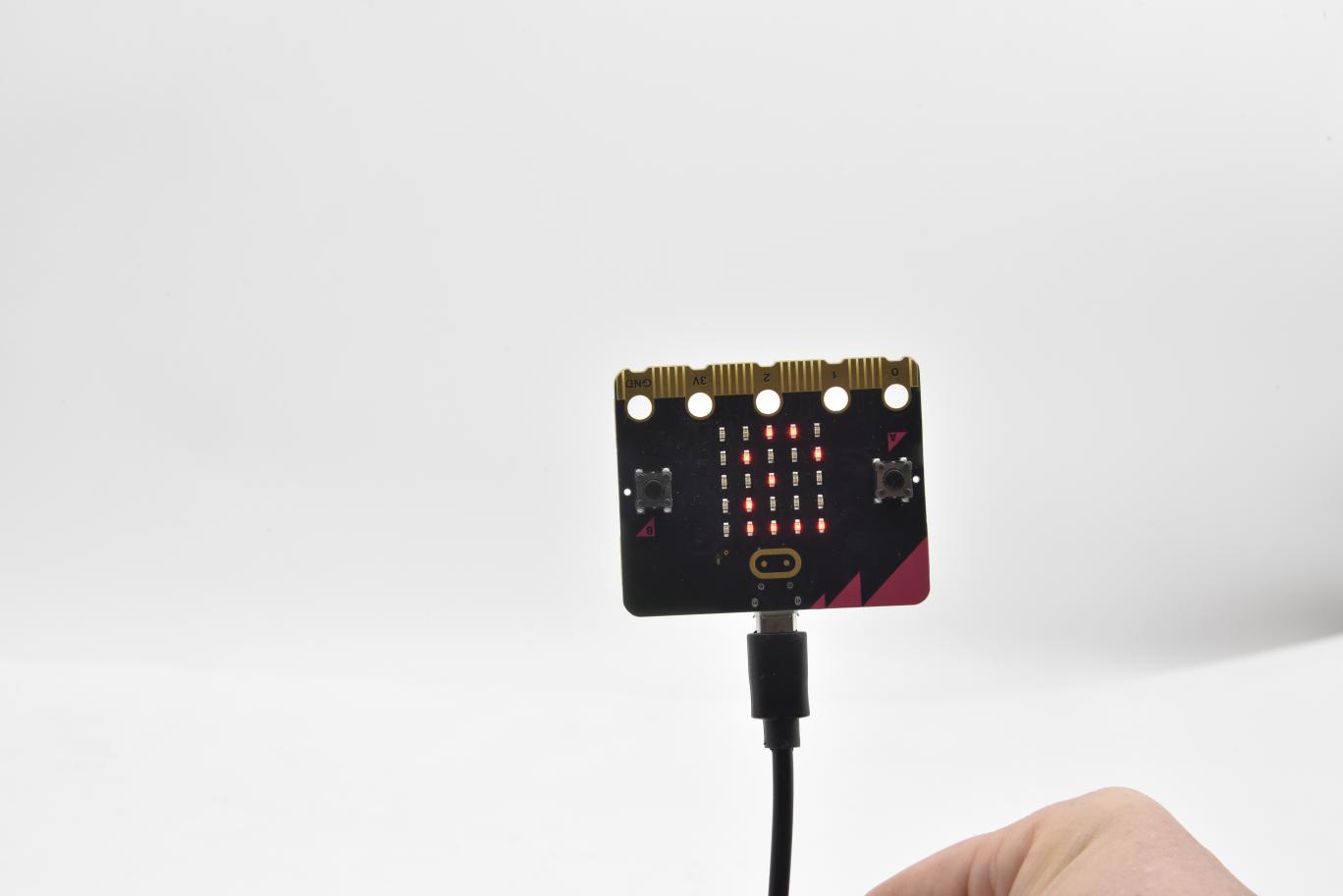

( 4 )Test Results 1:

After uploading the test code 1 to micro:bit main board V2 and powering the board via the USB cable, if we shake the Micro: Bit main board V2. no matter at any direction, the LED dot matrix displays the digit “1”.

When it is kept upright (its logo above the LED dot matrix), the number 2 will show.

When it is kept upside down( its logo below the LED dot matrix) , it will show as below.

When it is placed still on the desk, showing its front side, the number 4 appears.

When it is placed still on the desk, showing its back side, the number 5 will exhibit.

When the board is tilted to the left , the LED dot matrix shows the number 6 as shown below.

When the board is tilted to the right , the LED dot matrix displays the number 7 as shown below

When the board is knocked to the floor, this process can be considered as a free fall and the LED dot matrix shows the number 8. (please note that this test is not recommended for it may damage the main board.)

Attention: if you’d like to try this function, you can also set the acceleration to 3g, 6g or 8g. But still ,we don not recommend.

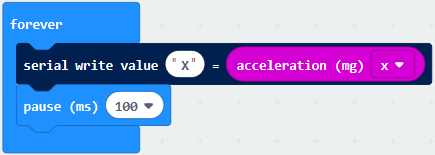

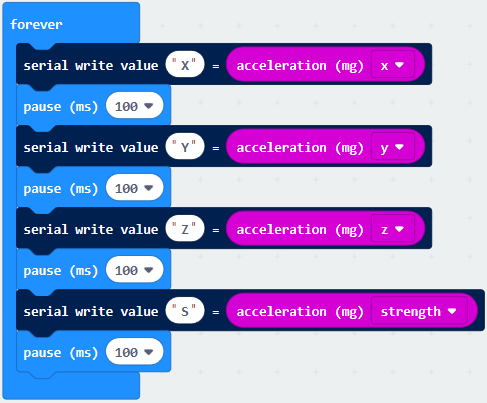

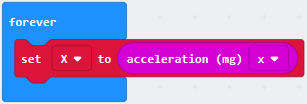

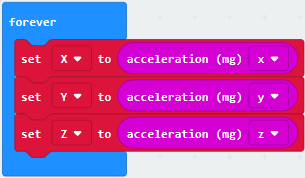

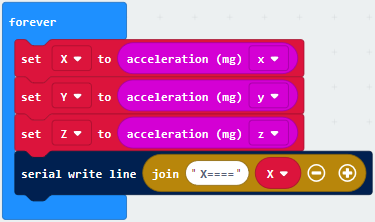

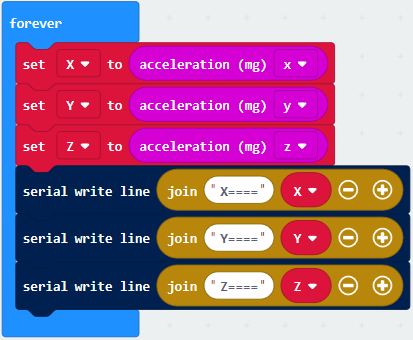

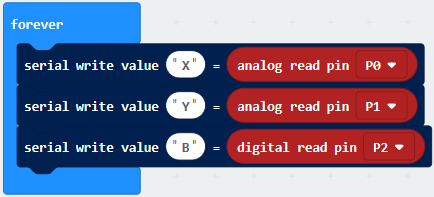

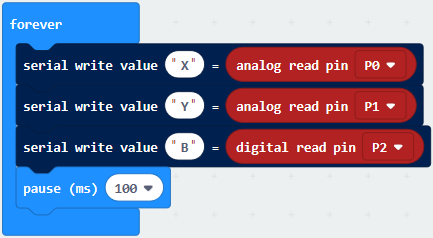

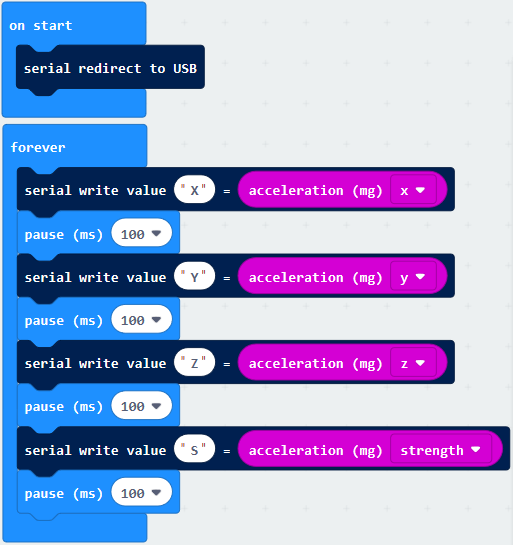

( 5 )Test Code 2:

A. Go to“Advanced”→“Serial”→“serial redirect to USB”

B. Drag it into“on start”

*****************************************************************

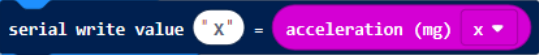

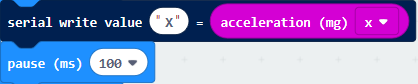

A. Enter“Serial”→“serial write value x =0”

B. Leave it into“forever”block

*****************************************************************

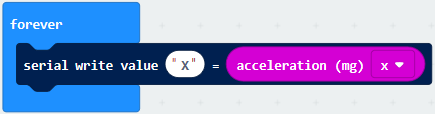

A. Click“Input”→“acceleration(mg) x”;

B. Keep it into“0”box and capitalize the“x”

*****************************************************************

Go to“Basic”and move out“pause (ms) 100”below the block , then set to 100ms.

, then set to 100ms.

*****************************************************************

Replicate code string for 3 times and keep them into“forever”block,separately set the whole code string as follows:

for 3 times and keep them into“forever”block,separately set the whole code string as follows:

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

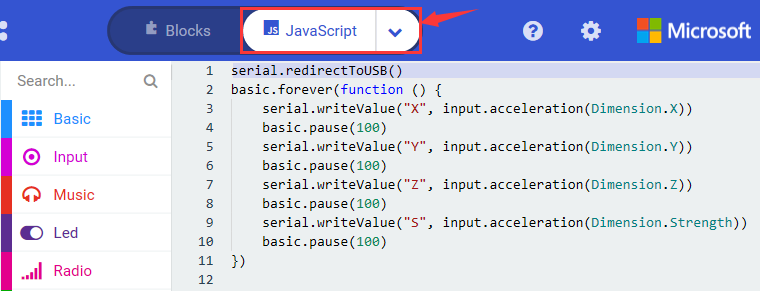

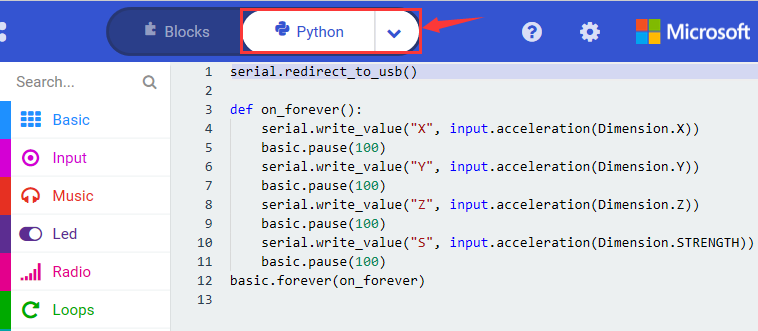

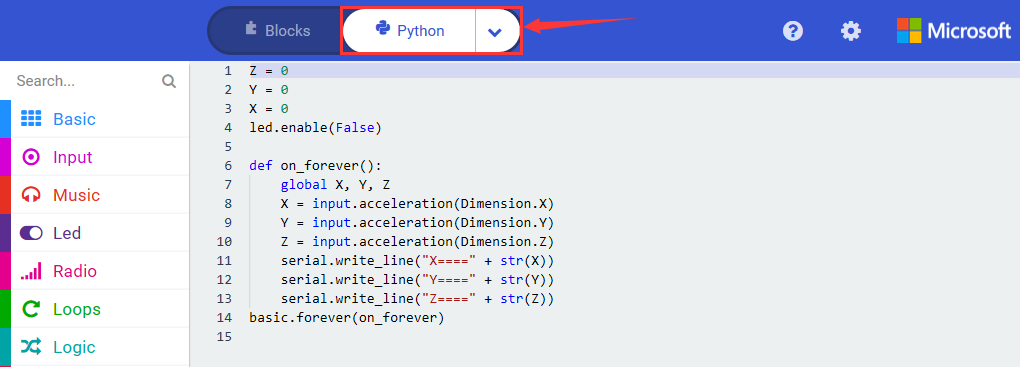

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 6 ) Test Results 2

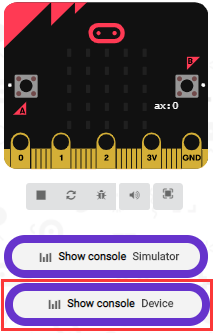

Upload test code to micro:bit main board V2, power the main board via the USB cable, and click “Show console Device”.

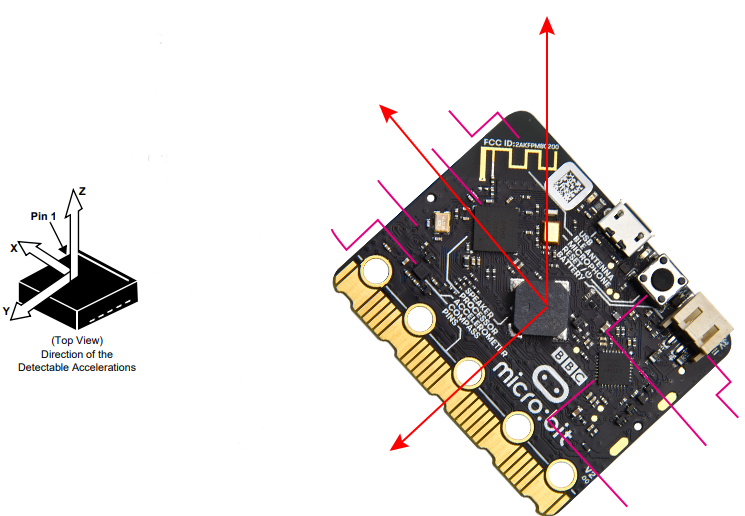

After referring to the MMA8653FC data manual and the hardware schematic diagram of the Micro: Bit main board V2, the accelerometer coordinate of the Micro: Bit V2 motherboard are shown in the figure below:

The following interface shows the decomposition value of acceleration in X axis, Y axis and Z axis respectively, as well as acceleration synthesis (acceleration synthesis of gravity and other external forces).

If you’re running Windows 7 or 8 instead of Windows 10, via Google Chrome won’t be able to match devices. You’ll need to use the CoolTerm serial monitor software to read data.

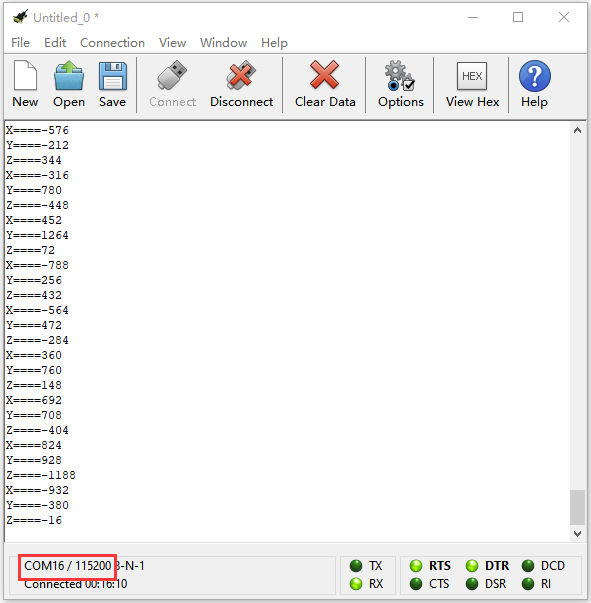

You could open CoolTerm software, click Options, select SerialPort, set COM port and baud rate to 115200 (after testing, the baud rate of USB SerialPort communication on Micro: Bit main board V2 is 115200), click OK, and Connect. The CoolTerm serial monitor shows the data of X axis, Y axis and Z axis , as shown in the figures below :

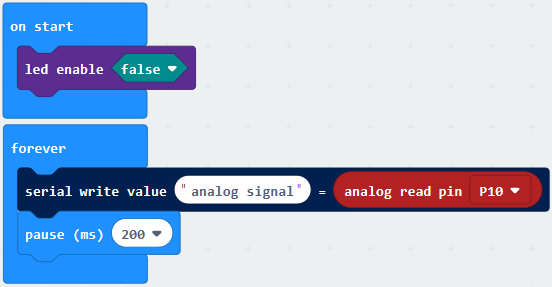

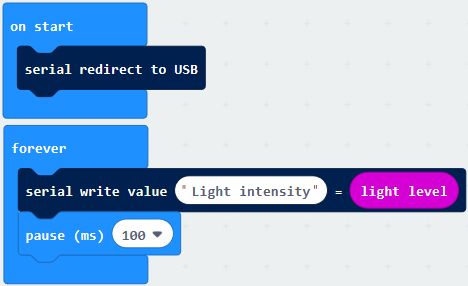

Project 8: Light Detection

( 1 )Project Description:

In this project, we focus on the light detection function of the Micro: Bit main board V2. It is achieved by the LED dot matrix since the main board is not equipped with a photoresistor.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

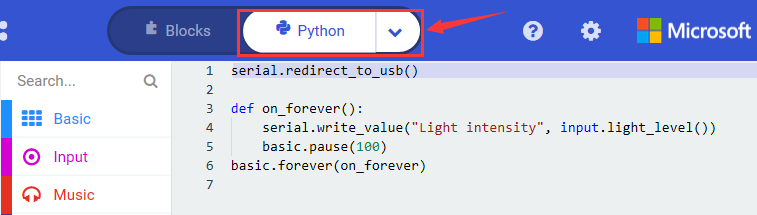

( 3 )Test Code:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor,

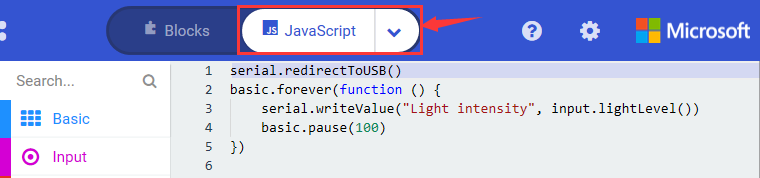

(1)A. Enter“Advanced”→“Serial”→“serial redirect to USB”;

B. Drag it into“on start”block.

*****************************************************************

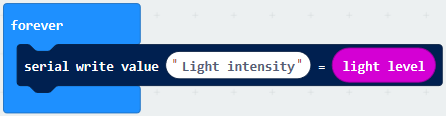

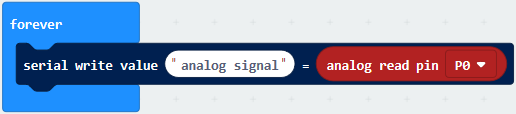

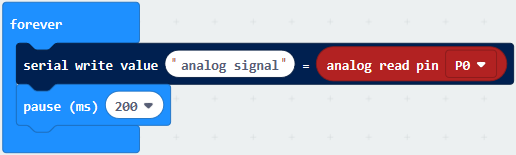

(2) A. Go to“Serial”→“serial write value x =0”;

B. Move it into“forever”

A. Click“Input”→“acceleration(mg) x”

B. Put“acceleration(mg) x”in the“0”box and change “x”into“Light intensity”.

*****************************************************************

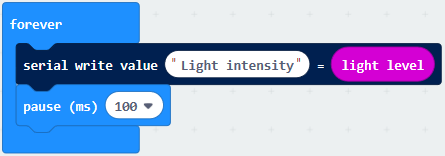

A. Click“Basic”→“pause (ms) 100”;

B. Lay it down into“forever”and set to 100ms.

*****************************************************************

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

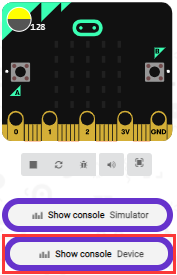

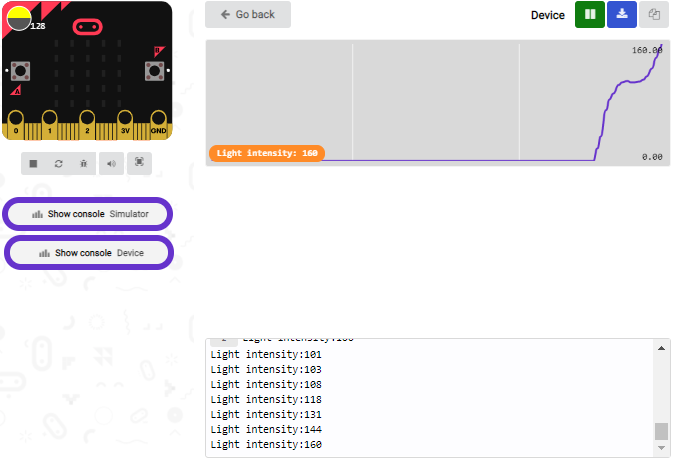

( 4 )Test Results:

Upload the test code to micro:bit main board V2, power the board via the USB cable and click “Show console Device”.

When the LED dot matrix is covered by hand, the light intensity showed is approximately 0; when the LED dot matrix is exposed to light,the light intensity displayed gets stronger with the light as shown below.

The 20 in the code is an arbitrary value of light intensity. If the current light level is less than or equal to 20, the moon will appear on the LED dot matrix. If it’s bigger than 20, the sun will appear.

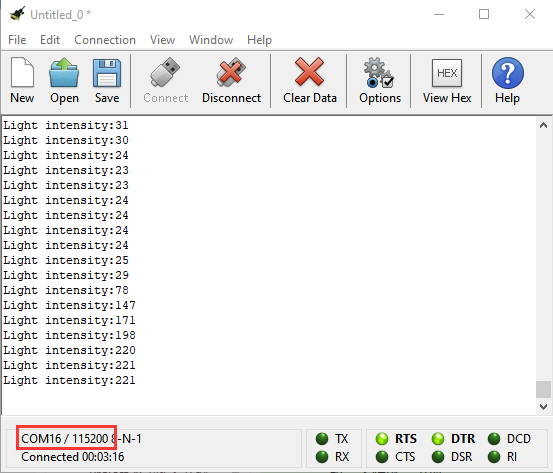

If you’re running Windows 7 or 8 instead of Windows 10, via Google Chrome won’t be able to match devices. You’ll need to use the CoolTerm serial monitor software to read data.

You could open CoolTerm software, click Options, select SerialPort, set COM port and baud rate to 115200 (after testing, the baud rate of USB SerialPort communication on Micro: Bit main board V2 is 115200), click OK, and Connect. The CoolTerm serial monitor shows the value of light intensity , as shown in the figures below :

Project 9: Speaker

( 1 )Project Description:

The Micro: Bit main board V2 has an built-in speaker, which makes adding sound to the programs easier. We can program the speaker to air all kinds of tones ,such as playing the song, “Ode to Joy” .

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3 )Test Code:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

(1) Enter“Basic”module to find “show icon”and drag it into “on start”block;

Click the little triangle to find “ ”

”

*****************************************************************

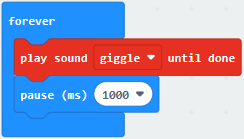

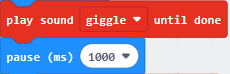

(2) Enter“Music”module to find and drug“play sound giggle until done” into “forever”block;

Enter“Basic”module to find and drug“pause(ms) 100” into “forever” block ;

Change 100 into 1000;

( 3 ) Copy  three times and place it into “forever” block ;

three times and place it into “forever” block ;

Click the little triangle to select “happy”,”hello”,”yawn”;

******************************************************

Complete Program:

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results:

After uploading the test code to micro:bit main board V2 and powering the board via the USB cable, the speaker utters sound and the LED dot matrix shows the logo of music.

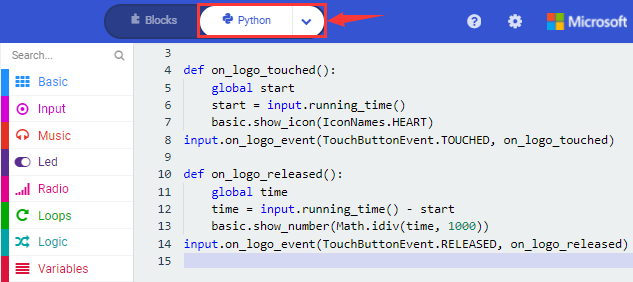

Project 10: Touch-sensitive Logo

( 1 )Project Description:

The Micro: Bit main board V2 is equipped with a golden touch-sensitive logo, which can act as an input component and function like an extra button.

It contains a capacitive touch sensor that senses small changes in the electric field when pressed (or touched), just like your phone or tablet screen do. When you press it , you can activate the program.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

( 3 )Test Code:

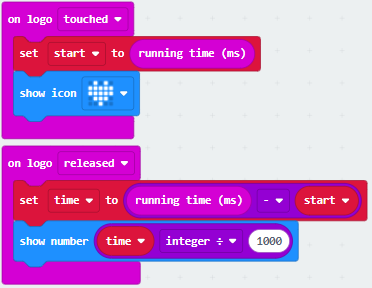

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor,

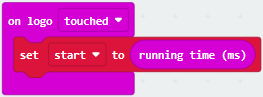

( 1 ) Delete block“on start”and“forever”;

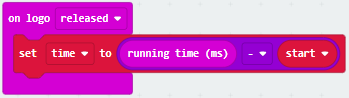

( 2 )Enter“Input”module to find and drag“on logo pressed” ;

Click the little triangle to find “touched”’;

( 3 ) Enter module “Variables”→choose“Make a Variable”→input “start”→click “OK”

The variable“start”is established;

Enter“Variables”module to find and drag “set start to 0” into “on logo touched”block;

( 4 )Enter“Input”module →click “more”→ find and drag“running time(ms)” into the “0”of“set start to 0”block;

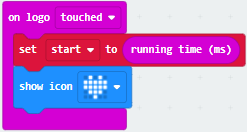

( 5 )Enter“Basic”module to find and drag“show icon ” into “on logo touched”block;

” into “on logo touched”block;

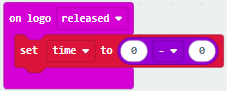

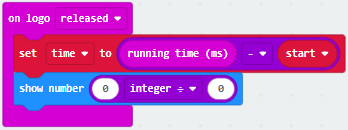

( 6 )Enter“Input”module to find and drag“on logo pressed”→choose “released”→ establish variable “time”;

Enter“Variables”module to find and drag “set time to 0”into “on logo pressed”block;

Enter“Math”module to find and drag “0-0”into the “0”of“set start to 0”block;

( 7 )Enter“Input”module→ “more” → find and drag “running time(ms)” into “0”on the left side of “0-0”;

Enter“Variables”module to find and drag“start” into “0”on the right side of “0-0”;

( 8 )Enter“Basic”module to find and drag“show number” into “on logo released”block;

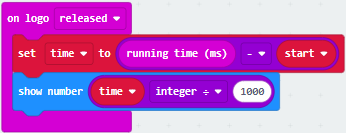

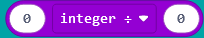

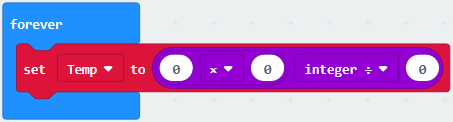

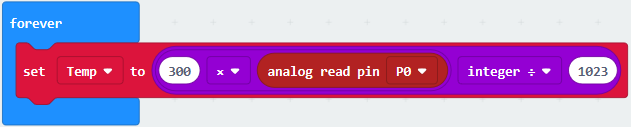

Enter“Math”module to find and drag“square root 0” into “0”; Click the little triangle to find”integer÷”;

( 9 ) Enter“Variables”module to find and drag“time” into “0”on the left side of “0-0”and change the “0”on the right side to”1000”;

Complete Program:

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results:

After uploading the test code to micro:bit main board V2 and powering the board via the USB cable, the LED dot matrix exhibits the heart pattern when the touch-sensitive logo is pressed or touched and displays digit when the logo is released.

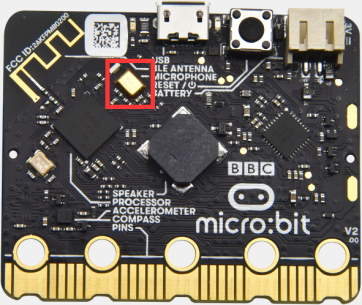

Project 11: Microphone

( 1 )Project Description:

The Micro: Bit main board V2 is built with a microphone which can test the volume of ambient environment. When you clap, the microphone LED indicator will turn on. Since it can measure the intensity of sound, you can make a noise scale or disco lighting changing with music. The microphone is placed on the opposite side of the microphone LED indicator and in proximity with holes that lets sound pass.When the board detects sound, the LED indicator lights up.

( 2 )Components Needed:

Micro:bit main board V2 *1

Micro USB cable*1

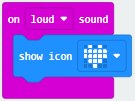

( 3 )Test Code 1:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

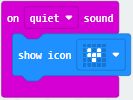

( 1 ) Delete block“on start”and“forever”;

( 2 ) Enter“Input”module to find and drag“on loud sound”;

Enter“Basic”module to find and drag “show number”into “on loud sound”block ;

( 3 )Copy  once;

once;

Click the little triangle of “lond” to choose”quiet”;

Click the little triangle of “ ” to choose”

” to choose” ”;

”;

Complete Program:

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 4 )Test Results 1:

After uploading test code to micro:bit main board V2 and powering the board via the USB cable, the LED dot matrix displays pattern“ ”when you claps and pattern

”when you claps and pattern  when it is quiet around.

when it is quiet around.

( 5 )Test Code 2:

Link computer with micro:bit board by micro USB cable, and program in MakeCode editor.

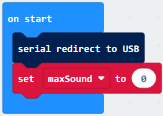

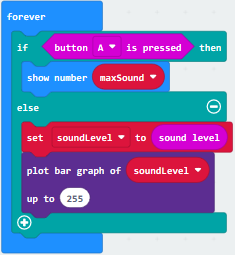

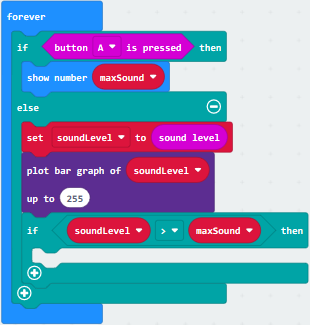

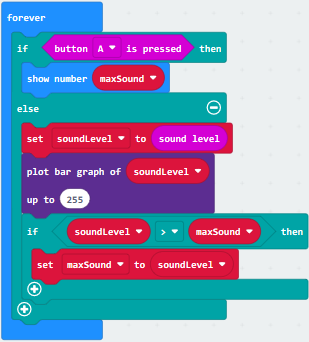

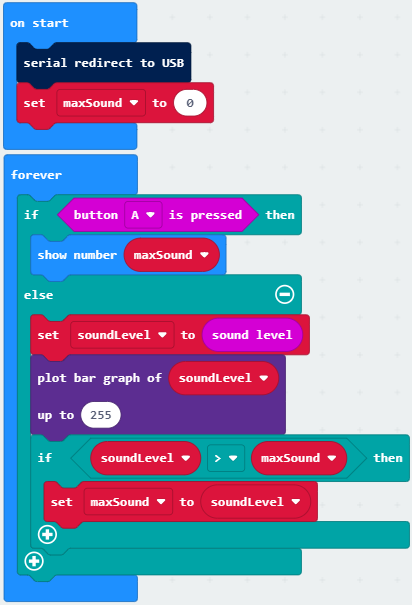

( 1 )Enter“Advanced”module→ choose“Serial”to find and drag“serial redirect to USB ”into “on start”block ;

( 2 )Enter“Variables”module→ choose“Make a Variable”→ input “maxSound”→click “OK”,variable ”maxSound”is established;

Enter“Variables”module to find and drag“set maxSound to 0”into “on start”block ;

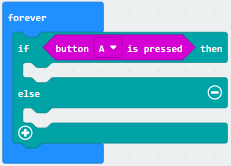

( 3 )Enter“Logic”module to find and drag“if true then…else”into “forever” block ;

Enter“Input”module to find and dragbutton A is pressed”into “then” ;

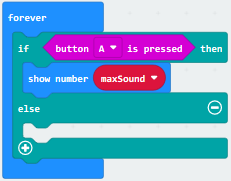

( 4 )Enter“Basic”module to find and drag“show number”into “then” ;

Enter“Variables”module to find and drag“maxSound”into “0” ;

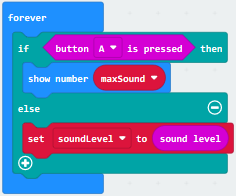

( 5 )Establish variable“soundLevel”;

Enter“Variables”module to find and drag“set soundLevel to 0”into “else”;

Enter“Input”module to find and drag“sound level” into “0”;

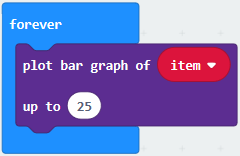

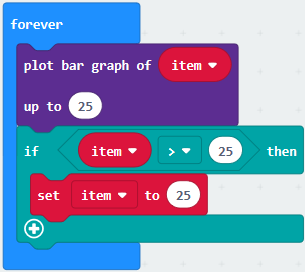

( 6 )Enter“Led”module to find and drag“plot bar graph of 0 up to 0” into “else”;

Enter“Variables”module to find and drag“soundLevel”into the“0”behind “of”;

Change the “0”behind “up” to “255”;

( 7 )Enter“Logic”module to find and drag“if true then”into “else”block ;

Enter“Logic”module to find and drag“0 > 0”into “then” ;

Enter“Variables”module to find and drag“soundLevel”into “0”on the left side of “0-0” ;

Enter“Variables”module to find and drag“maxSound” into “0” on the right side;

( 8 )Enter“Variables”module to find and drag“set maxSound to 0”into the second “then” ;

Enter“Variables”module to find and drag“soundLevel”into the “0” ;

Complete Program:

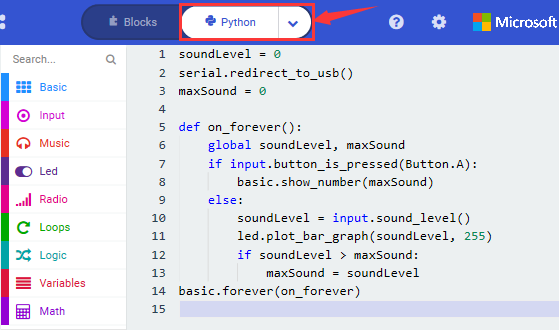

Select“JavaScript” and“Python”to switch into JavaScript and Python language code:

( 6 )Test Results 2:

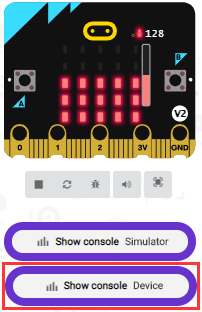

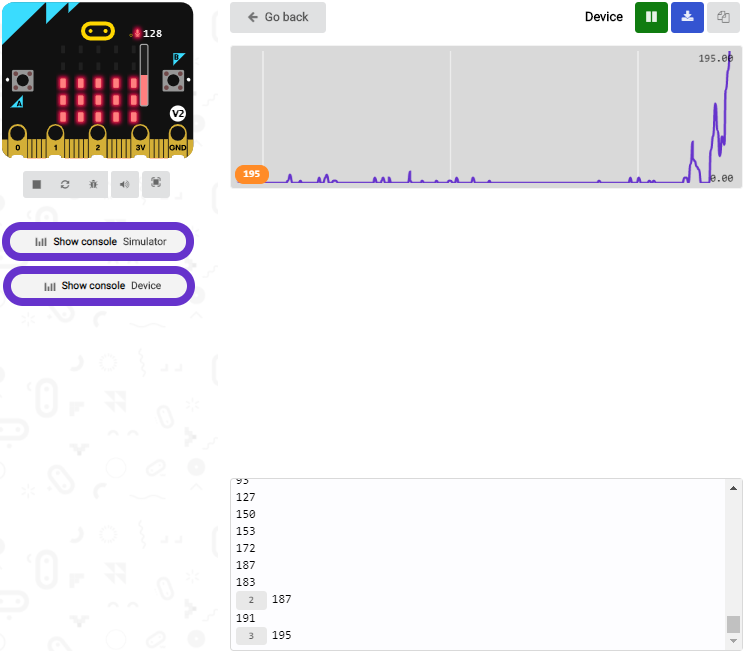

Upload test code to micro:bit main board V2, power the board via the USB cable and click “Show console Device”as shown below.

When the sound is louder around, the sound value shows in the serial port is bigger as shown below.

What’s more, when pressing the button A, the LED dot matrix displays the value of the biggest volume( please note that the biggest volume can be reset via the Reset button on the other side of the board ) while when clapping, the LED dot matrix shows the pattern of the sound.

Project 12: Bluetooth Data Reading

( 1 )Project Description:

The Micro: Bit main board V2 comes with a nRF52833 processor (with built-in Bluetooth 5.1 BLE(Bluetooth Low Energy) device) and a 2.4GHz antenna for Bluetooth wireless communication and 2.4GHz wireless communication. With the help of them, the board is able to communicate with a variety of Bluetooth devices, including smart phones and tablets.

In this project, we mainly concentrate on the Bluetooth wireless communication function of this main board. Linked with Bluetooth, it can transmit code or signals. To this end, we should connect an Apple device (a phone or an iPad) to the board.

Since setting up Android phones to achieve wireless transmission is similar to that of Apple devices, no need to illustrate again.

( 2 ) Preparation

Attach the Micro:bit main board V2 to your computer via the Micro USB cable.

An Apple device (a phone or an iPad) or an Android device;

( 3 ) Procedures:

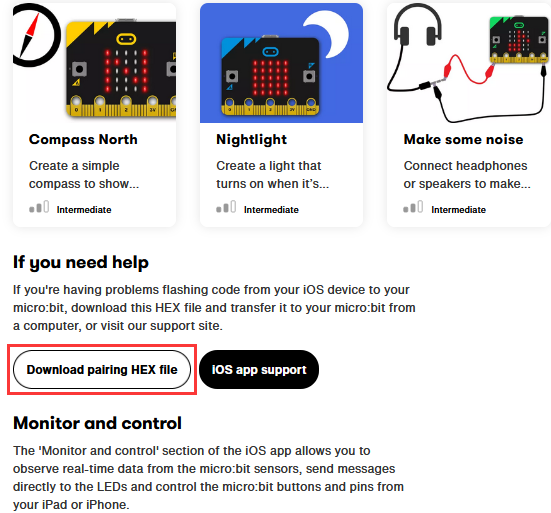

For Apple devices, enter this link https://www.microbit.org/get-started/user-guide/ble-ios/ with your computer first, and then click “Download pairing HEX file”to download the Micro: Bit firmware to a folder or desk, and upload the downloaded firmware to the Micro: Bit main board V2.

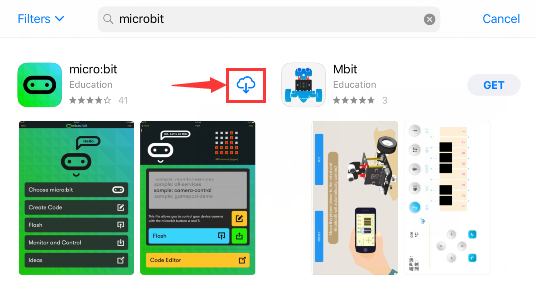

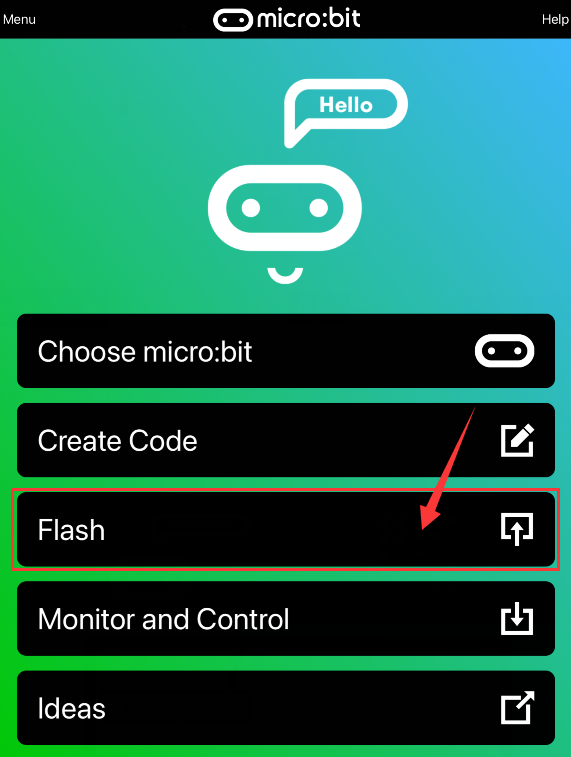

Search “micro bit”in your App Store to download the APP micro:bit.

Connect your Apple device with Micro: Bit main board V2:

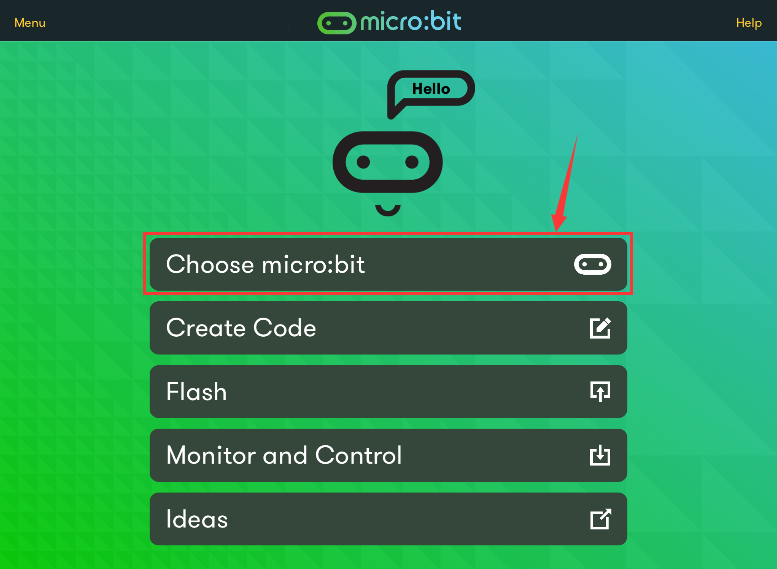

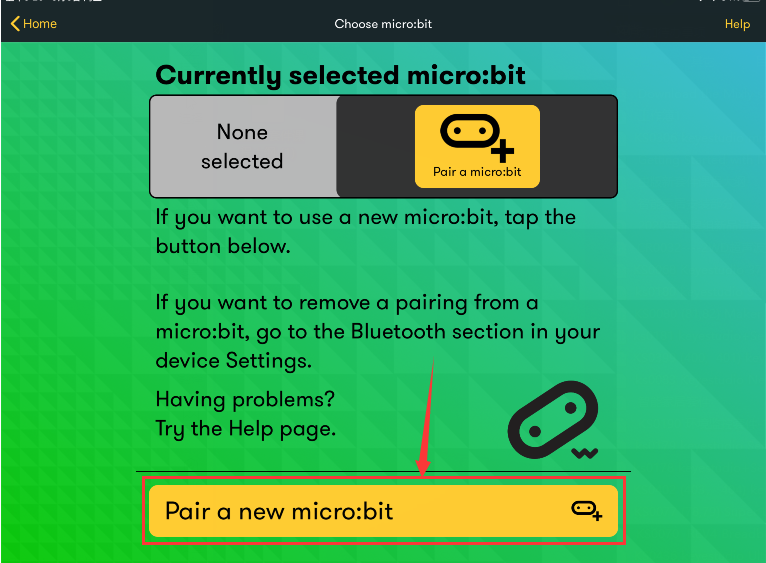

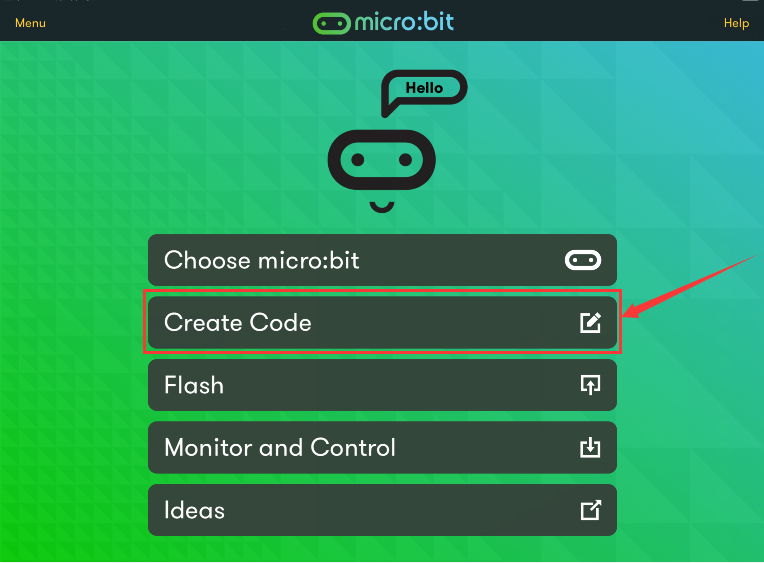

Firstly, turn on the Bluetooth of your Apple device and open the APP micro:bit to select item “Choose micro:bit” to start pairing Bluetooth.

Please make sure that the Micro: Bit main board V2 and your computer are still linked via the USB cable.

Secondly, click “Pair a new micro:bit”;

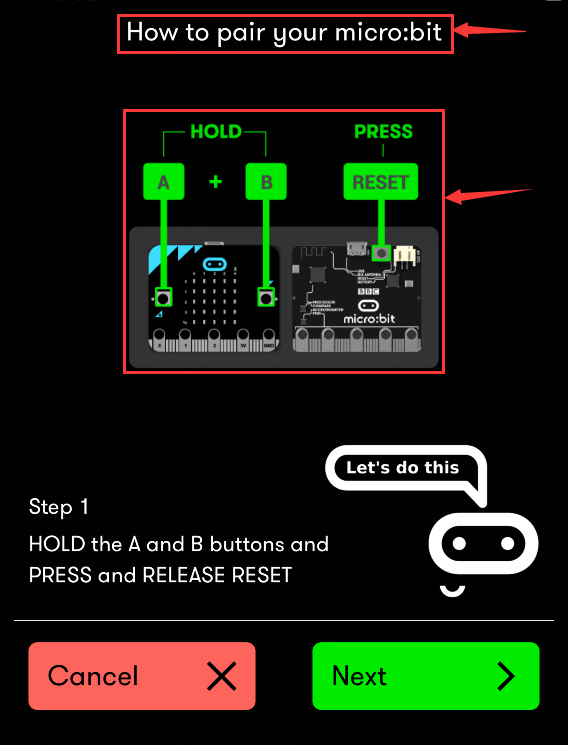

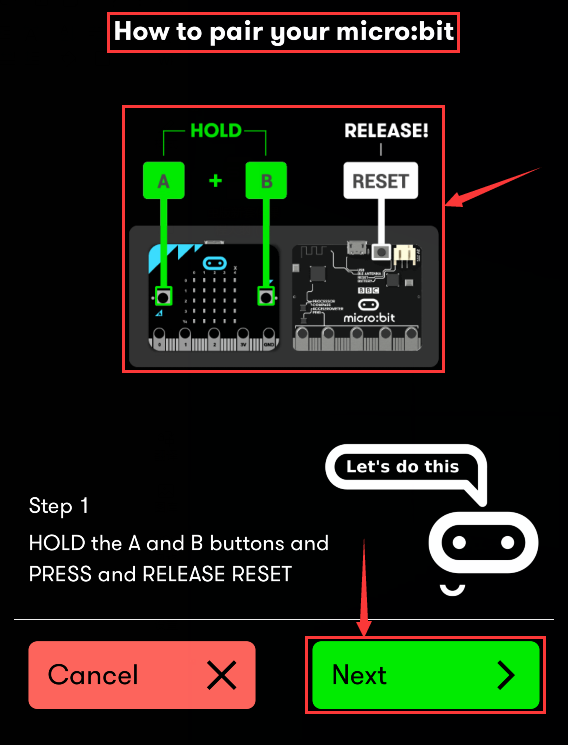

Following the instructions to press button A and B at the same time(do not release them until you are told to) and press Reset & Power button for a few seconds.

Release the Reset & Power button, you will see a password pattern shows on the LED dot matrix. Now , release buttons A and B and click Next.

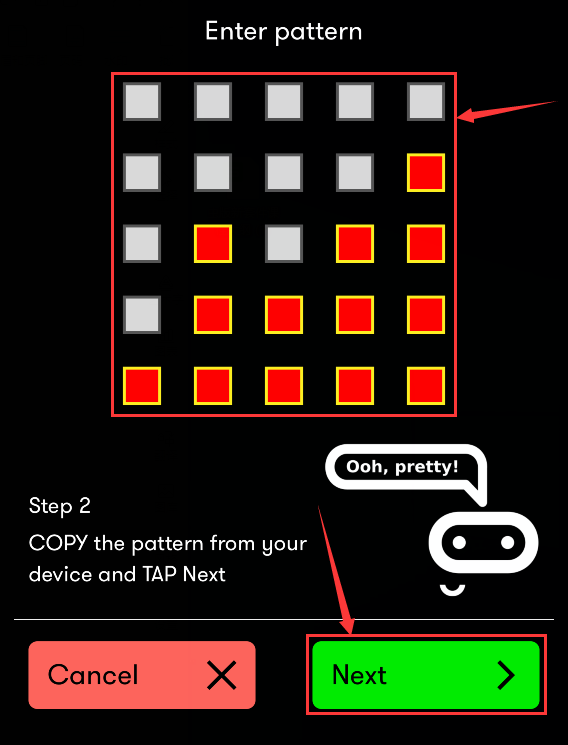

Set the password pattern on your Apple device as the same pattern showed on the matrix and click Next.

Still click Next and a dialog box props up as shown below. Then click “Pair”. A few seconds later, the match is done and the LED dot matrix displays the “√” pattern.

After the match with Bluetooth, write and upload code with the App.

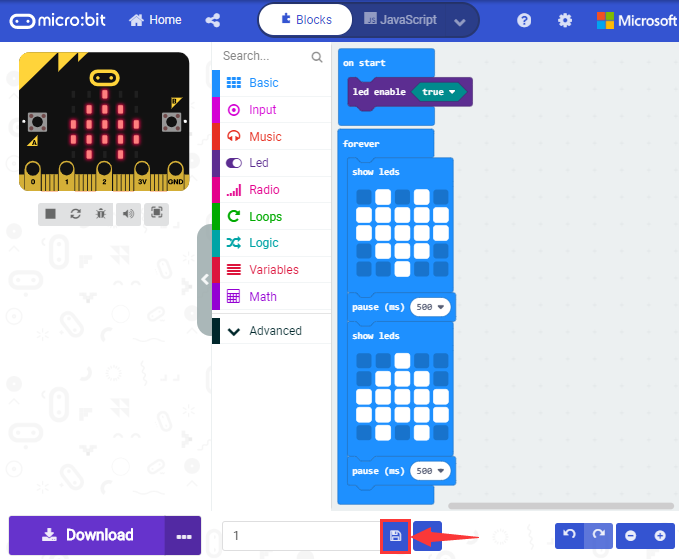

Click “Create Code” to enter the programming page and write code.

Click  and the box

and the box  appears, and then select “Create √”.

appears, and then select “Create √”.

Name the code as “1 “and click  to save it.

to save it.

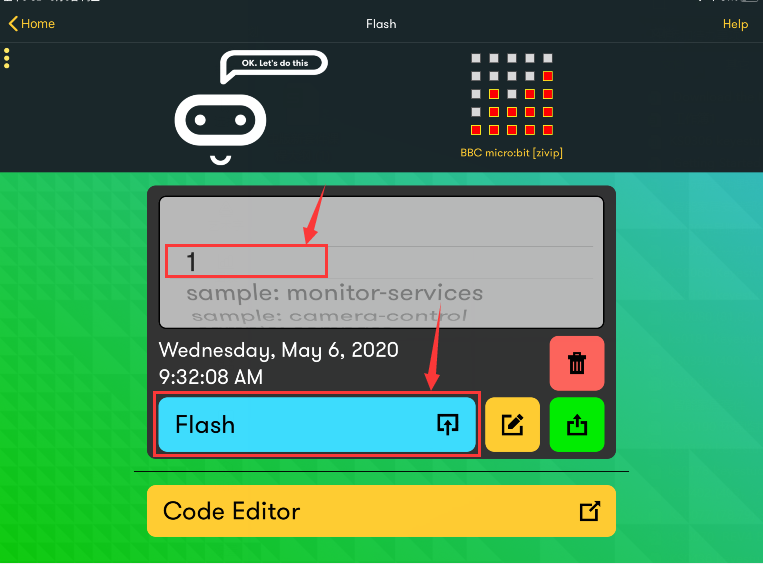

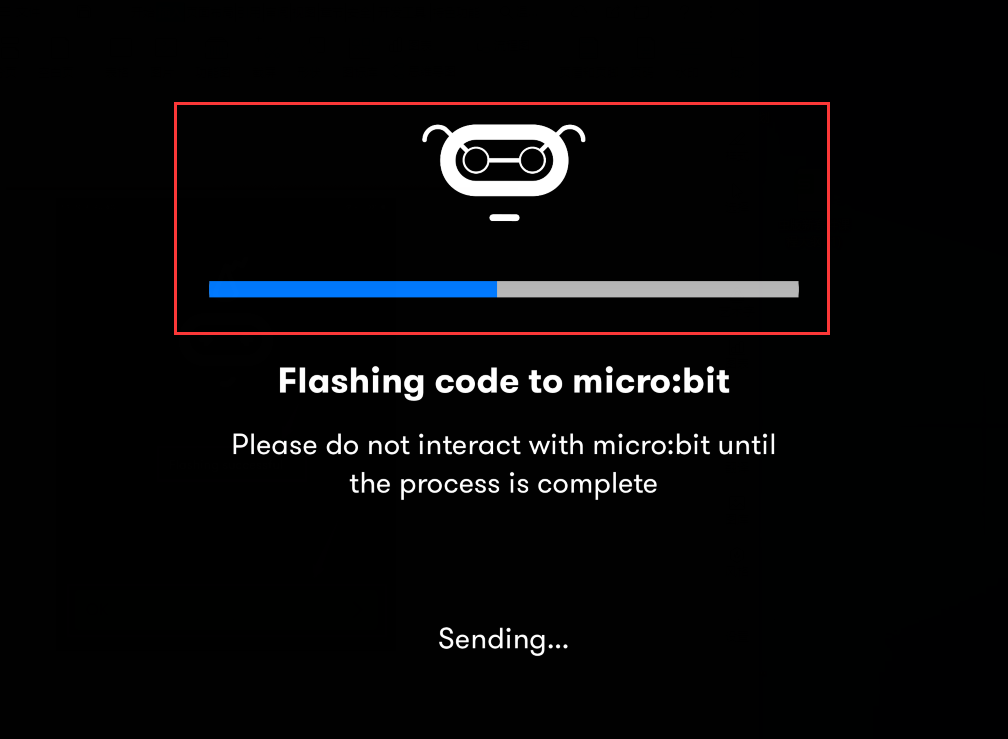

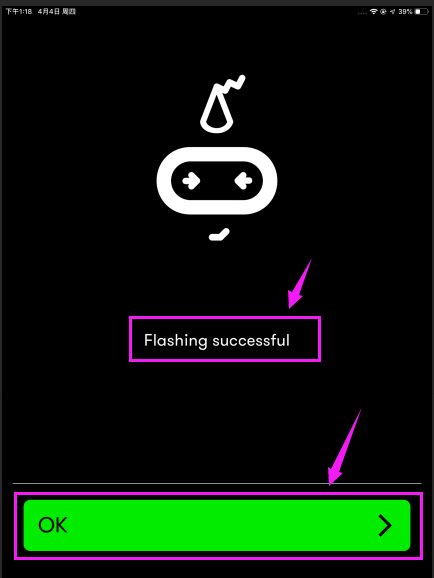

Click the third item“Flash”to enter the uploading page. The default code program for uploading is the one saved just now and named “1” and then click the other “Flash” to upload the code program “1”.

If the code is uploaded successfully a few seconds later, the App will emerge as below and the LED dot matrix of the Micro: Bit main board V2 will exhibit a heart pattern.

Projects below all conduct with the built-in sensors and the LED dot matrix while the following ones will carry out with the help of external sensors.

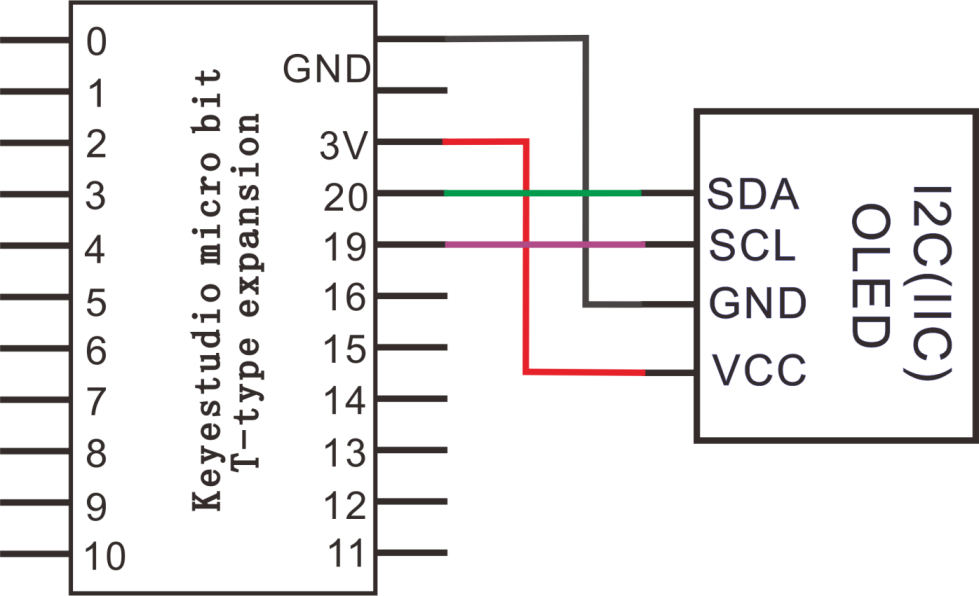

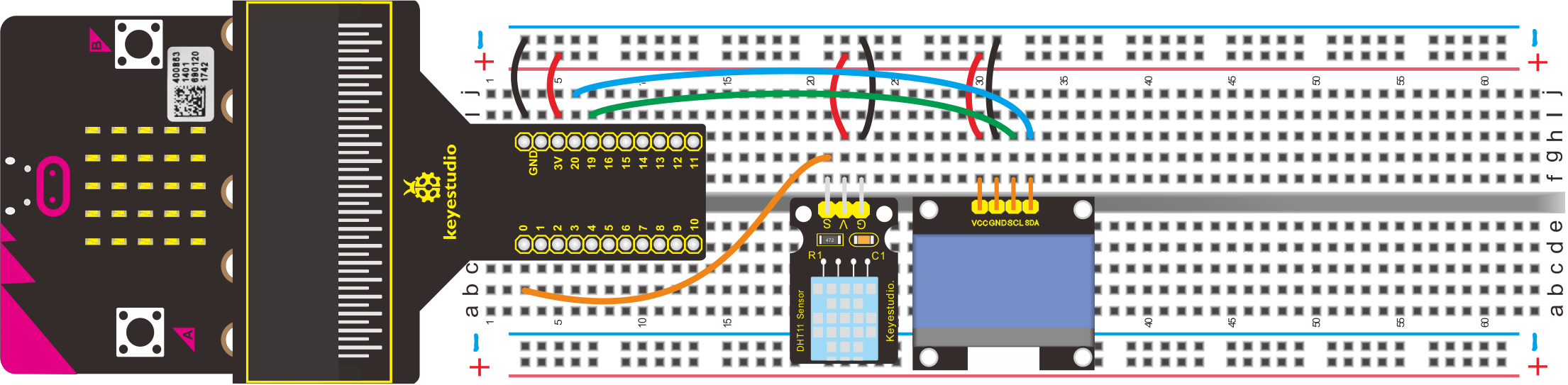

(Attention: to avoid burning the the Micro:bit main board V2, please remove the USB cable and the external power from the board before fix it with a T-shaped shield; likewise, the USB cable and the external power should be cut from the main board before disconnect the shield from the board.)

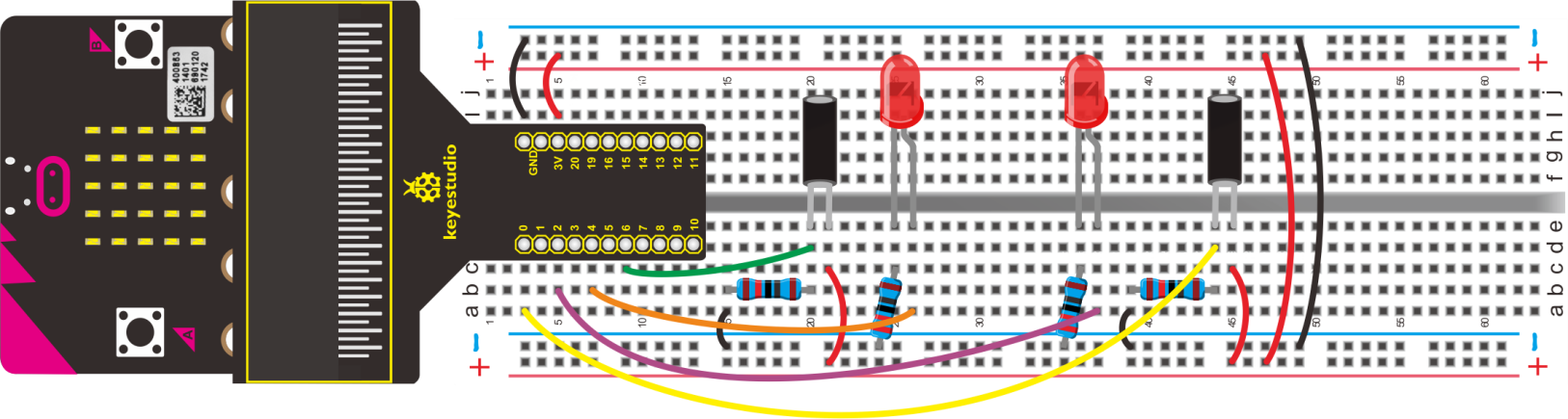

Project 13:LED Blinks

Description:

Making LED blink is one of the primary project. We used to control the LEDs of the dot matrix built in the micro:bit board to flash. But in this lesson, we plan to link the board with an external LED and control it. Thus, we also need to block the dot matrix when we conduct this experiment.

LED(light-emitting diode):

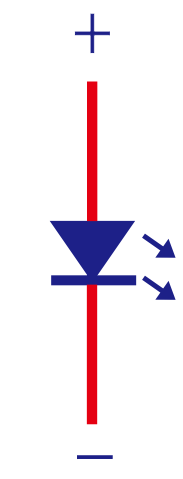

LED is a type of semiconductor called “Light Emitting Diode “which is an electronic device made of semiconductor materials (silicon, selenium, germanium, etc.).

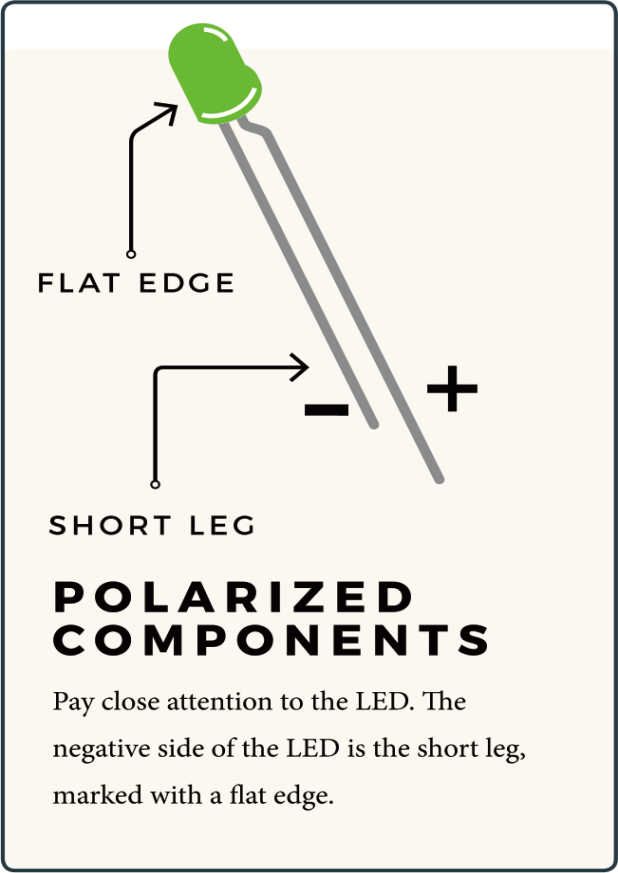

It features unidirectional conductivity, that is, the positive voltage is applied to the anode (long leg) and the cathode (short leg) of the diode. when the voltage of its anode is higher than the voltage of its cathode, thus, the diode is turned on(LED is on). When a reverse voltage is applied to the anode and cathode, the diode is disconnected(that is, the LED is off).

Therefore, the disconnection and connection of the diode is equivalent to turning on and off LED. Light-emitting diodes have an anode (+) and a cathode (-), and they can only allow current to flow from one anode to the cathode. The components will be damaged if LED is directly connected to the power supply. It’s essential that a certain resistor must be connected in series in the LED circuit.

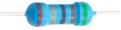

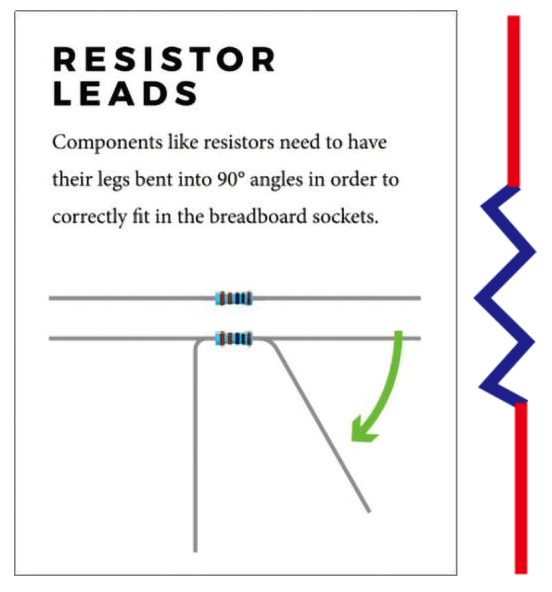

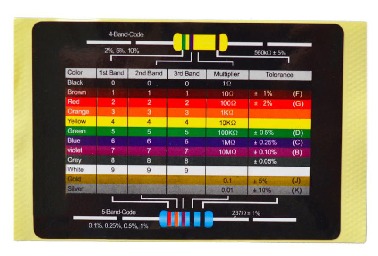

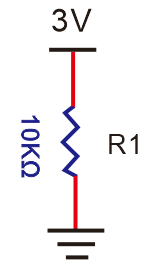

3. Resistor

Resistor is the electronic component in the circuit, which limits and regulates current flow. Its unit is (Ω). 1 mΩ= 1000 kΩ,1kΩ= 1000Ω.

It is used to protect the sensitive elements, like LED. The color ring on its body represents a number. You could follows the resistor color chart.

Under the same voltage, there are smaller or higher current.

The relationship between current, voltage, and resistor can be expressed by the formula: I=U/R. In the figure below, the current flowing through R1: I = U / R = 3 V / 10 KΩ = 0.000 3A = 0.3mA.

Don’t connect resistor with low resistance to the ends of power, which will damage electronic components due to high current. There is no difference of positive or negative poles for resistors.

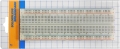

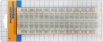

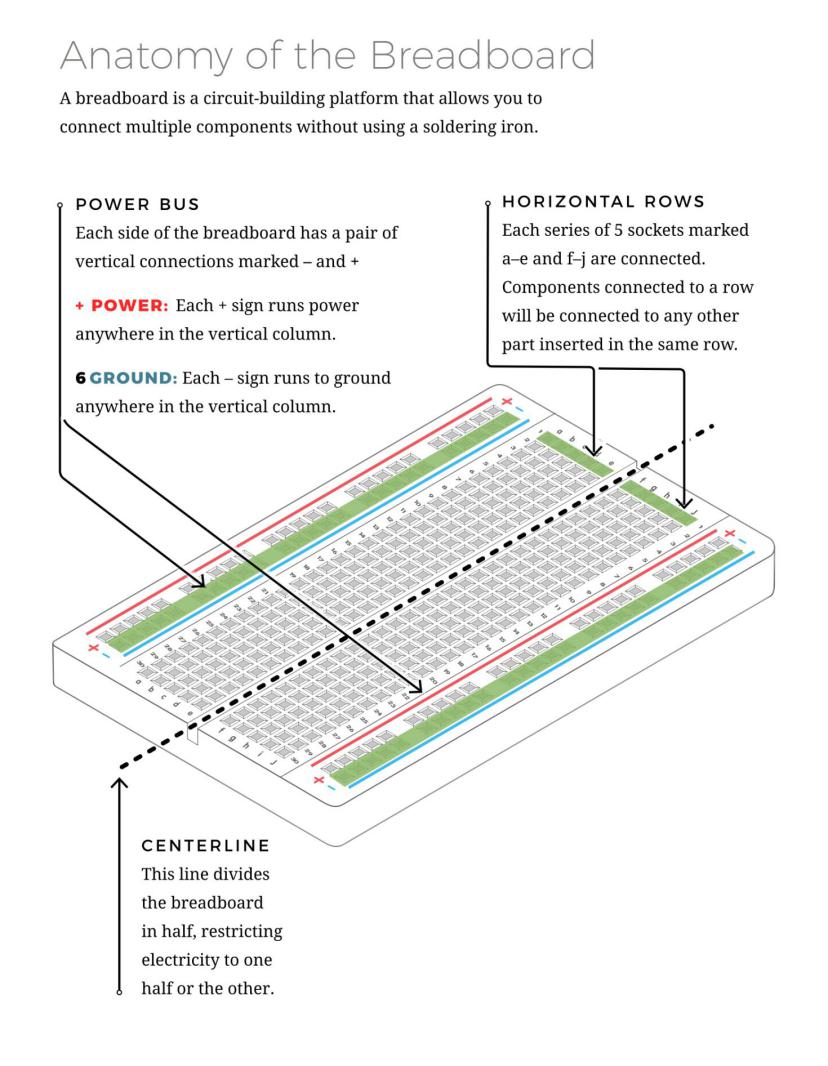

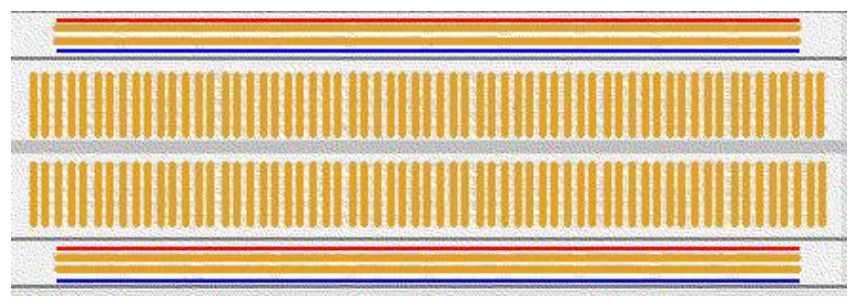

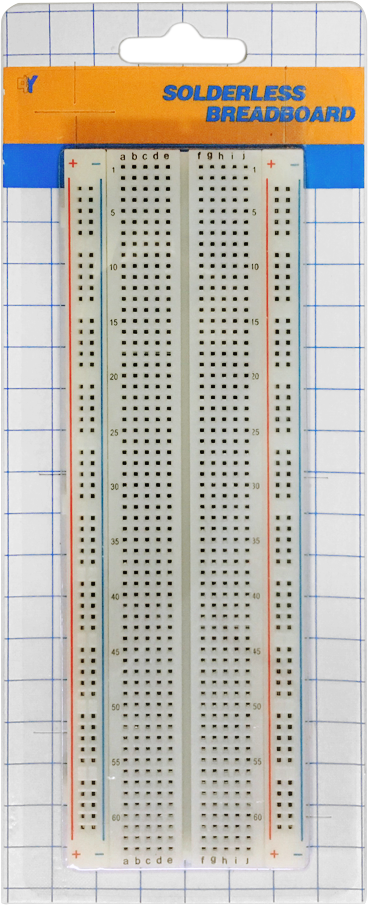

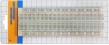

4. Breadboard

Breadboard is the essential tool in building circuit. The reasonable use of breadboard highly boost the efficiency.

Firstly, let’s the basic knowledge of breadboard.

A breadboard is used to build and test circuits quickly before finalizing any circuit design. The breadboard has many holes into which circuit components like ICs and resistors can be inserted. A typical breadboard is shown below:

The bread board has strips of metal which run underneath the board and connect the holes on the top of the board.The metal strips are laid out as shown below. Note that the top and bottom rows of holes are connected horizontally while the remaining holes are connected vertically.

To use the bread board, the legs of components are placed in the holes. Each set of holes connected by a metal a strip underneath forms anode.

A node is a point in a circuit where two components are connected. Connections between different components are formed by putting their legs in a common node.

The long top and bottom row of holes are usually used for power supply connections. The rest of the circuit is built by placing components and connecting them together with jumper wires.

ICs are placed in the middle of the board so that half of the legs are on side of the middle line and half on the other.

5. Components List:

Micro:bit Main board*1 |

keyestudio Micro:bit T type shield |

Red LED*1 |

Micro USB cable*1 |

|---|---|---|---|

|

|

|

|

220Ω Resistor*1 |

Breadboard*1 |

Breadboard wire |

|

|

|

|

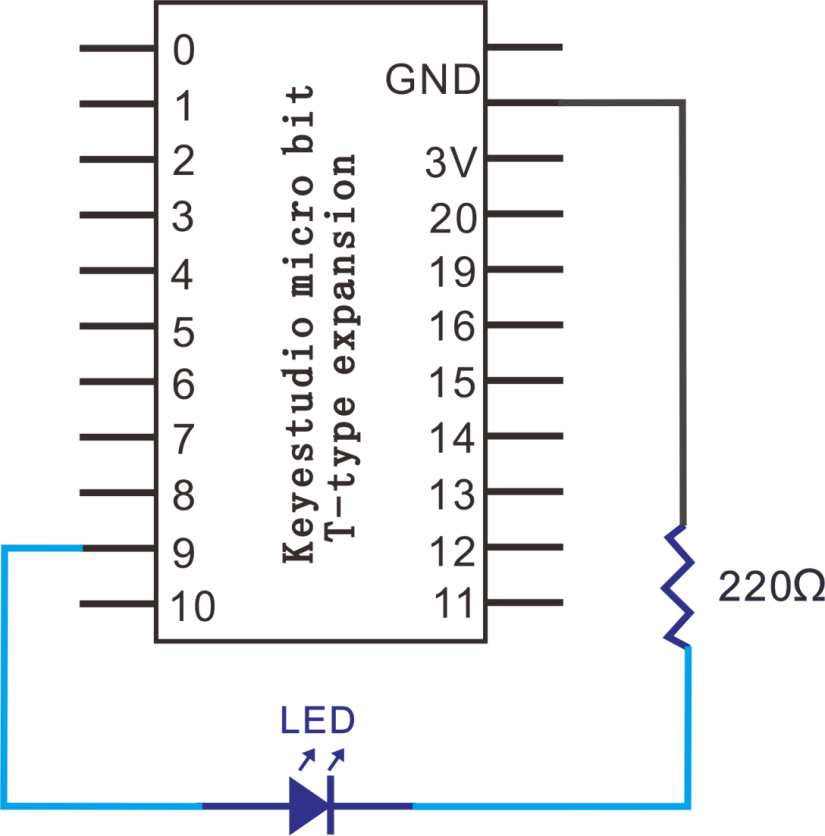

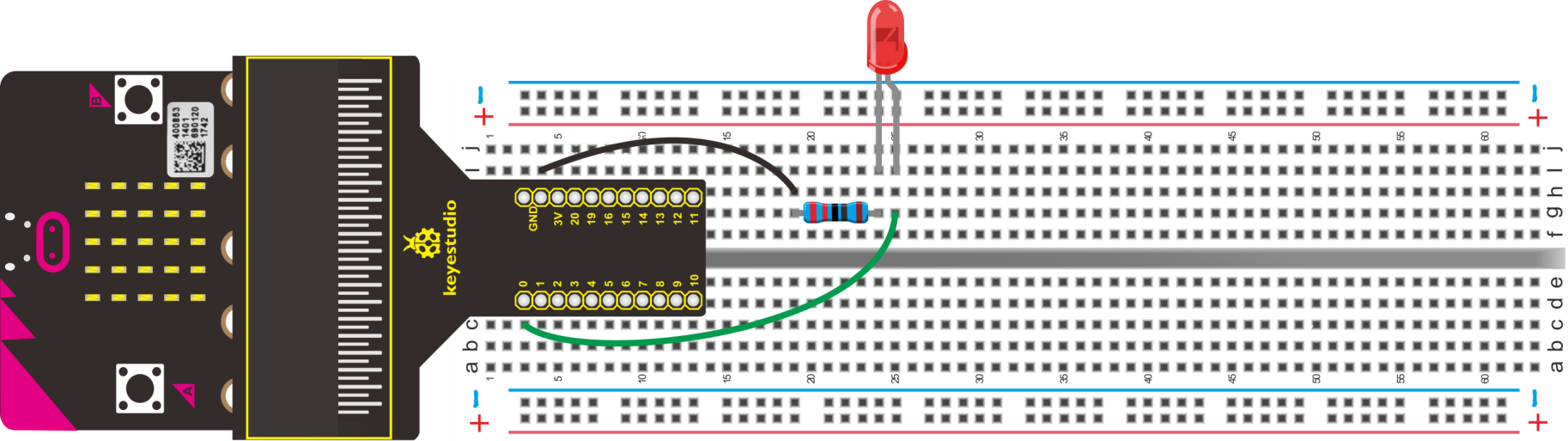

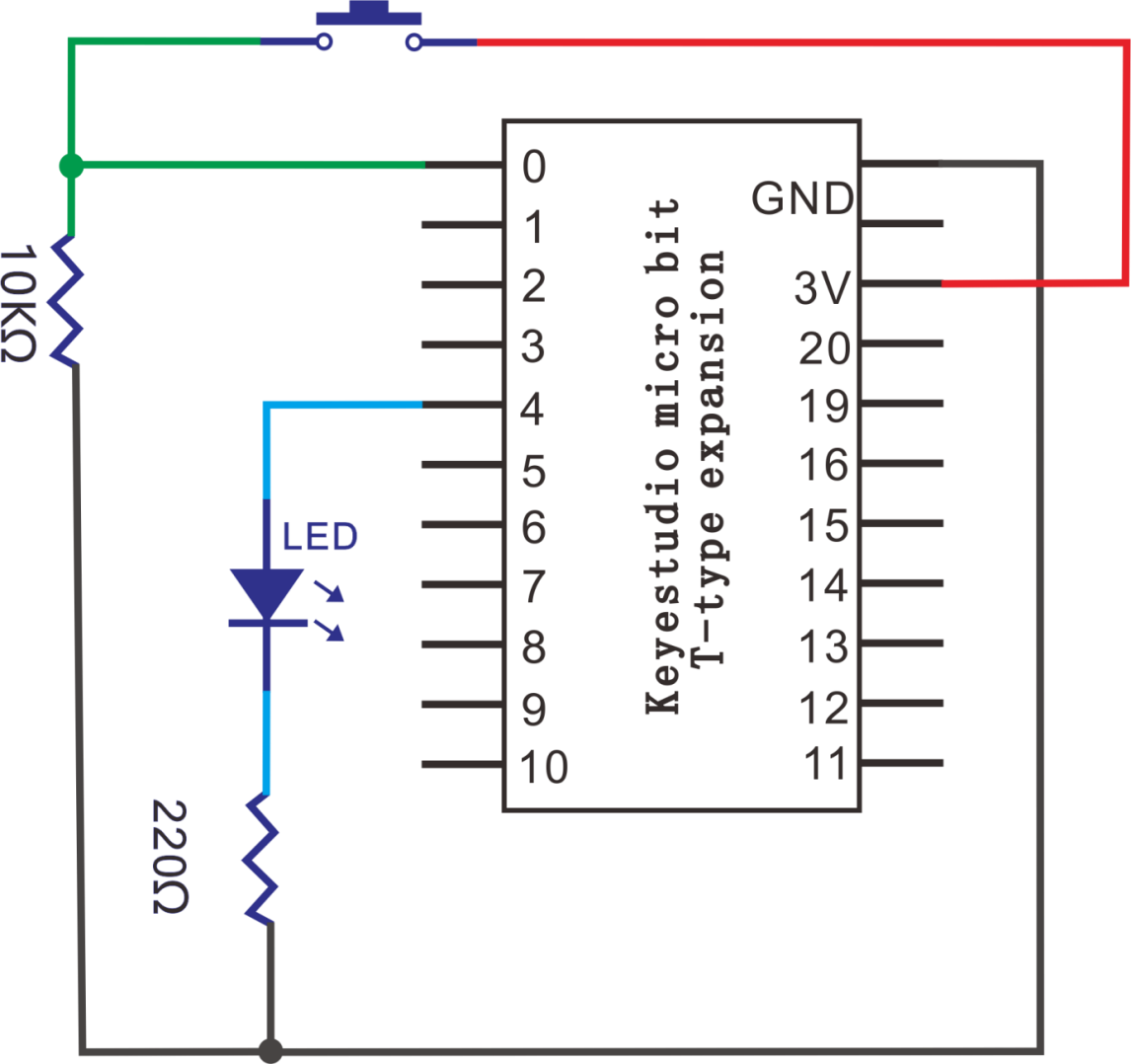

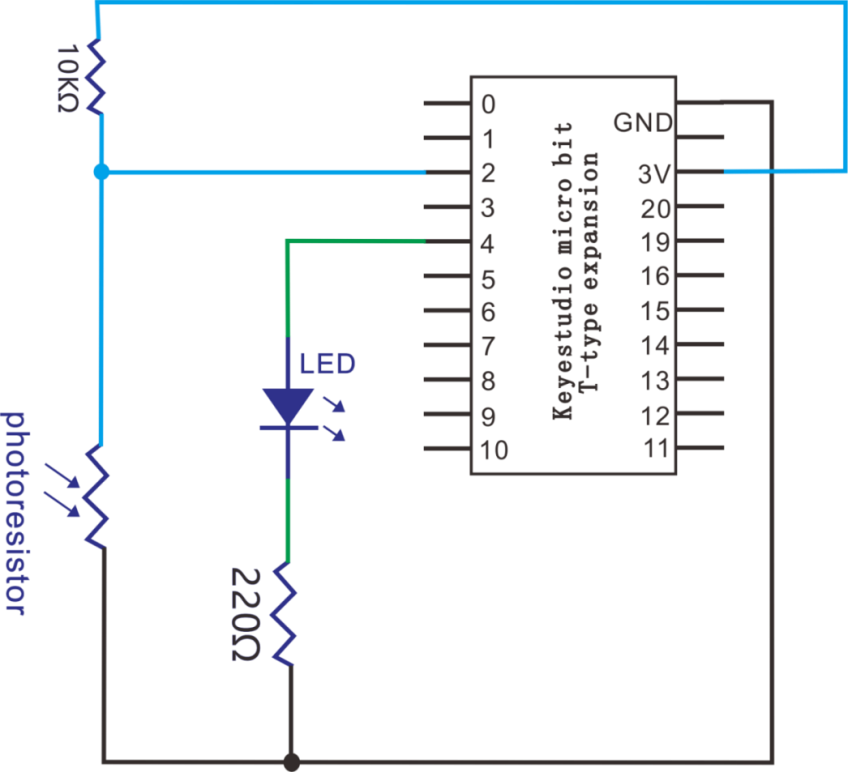

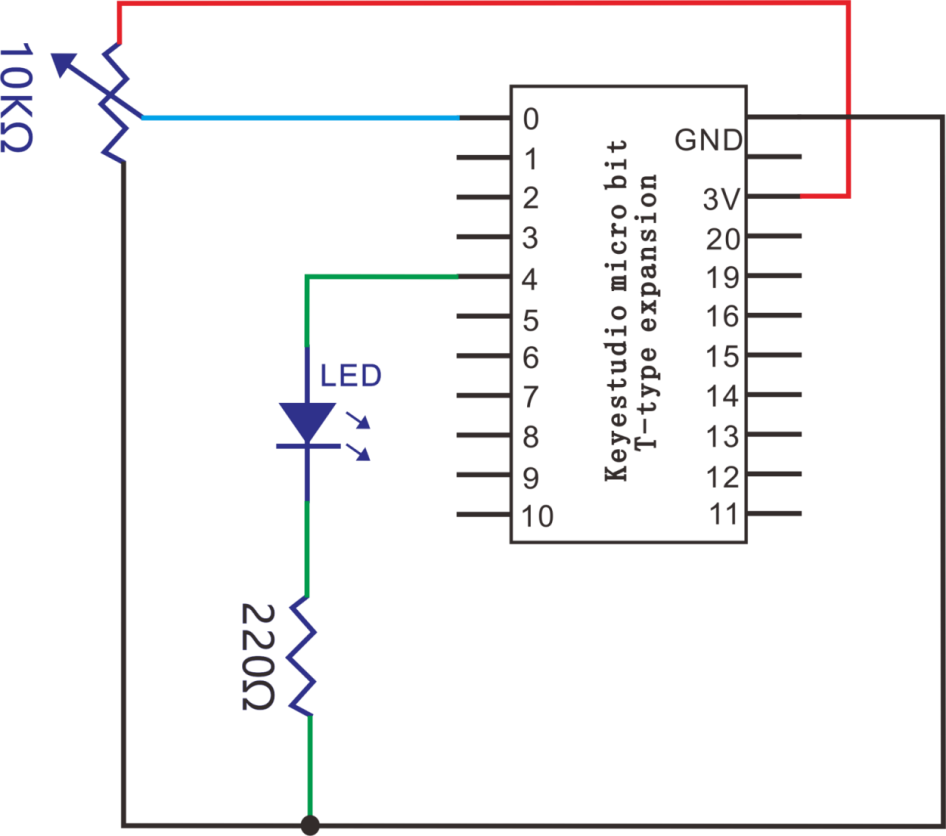

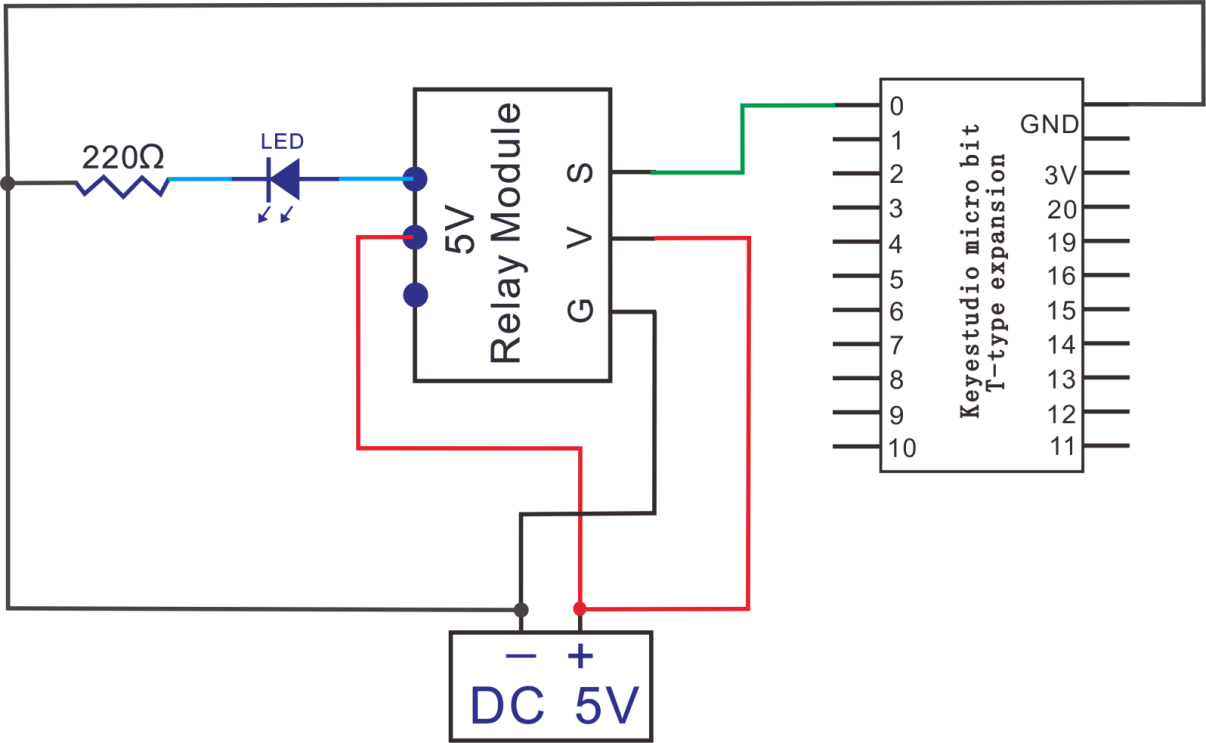

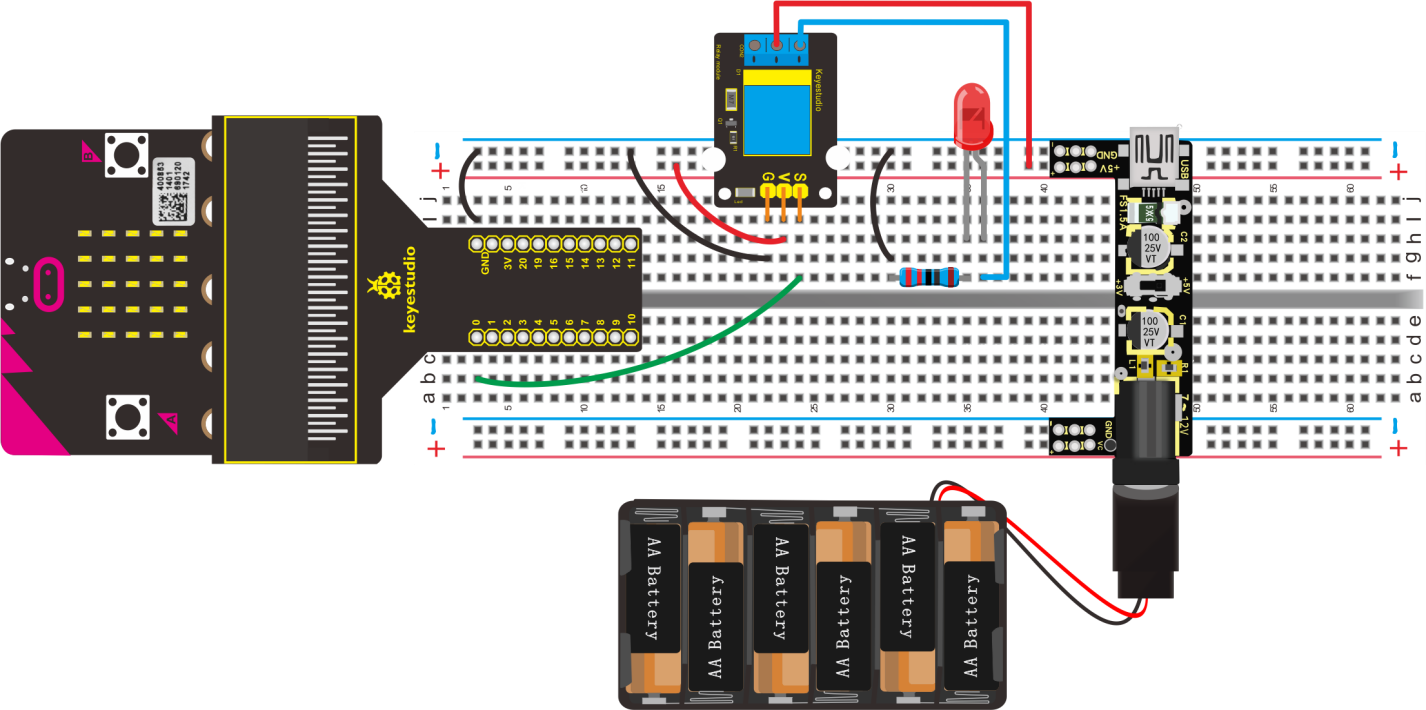

Schematic Diagram:

>

>

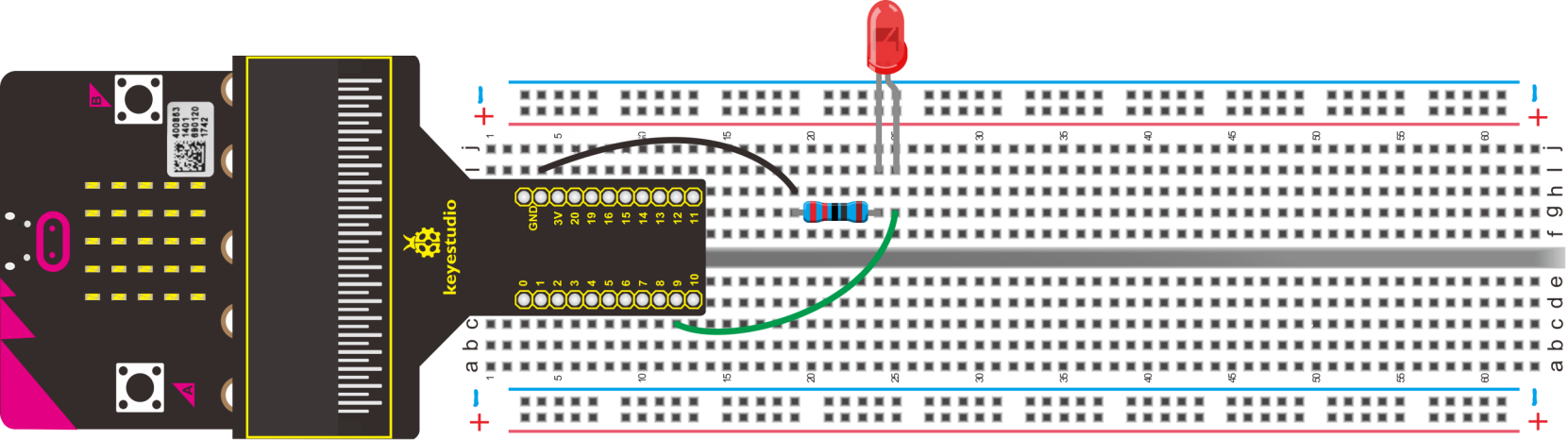

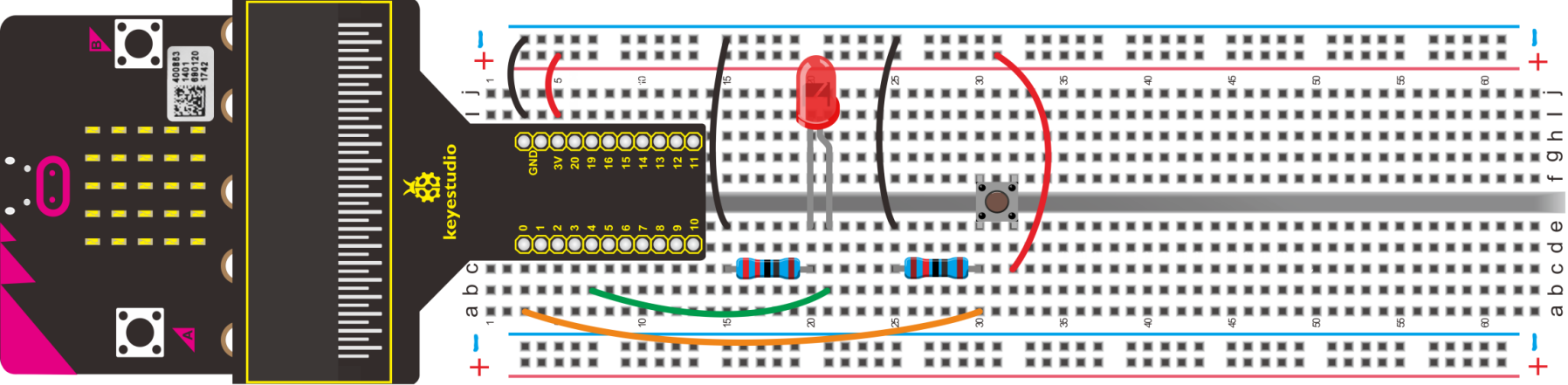

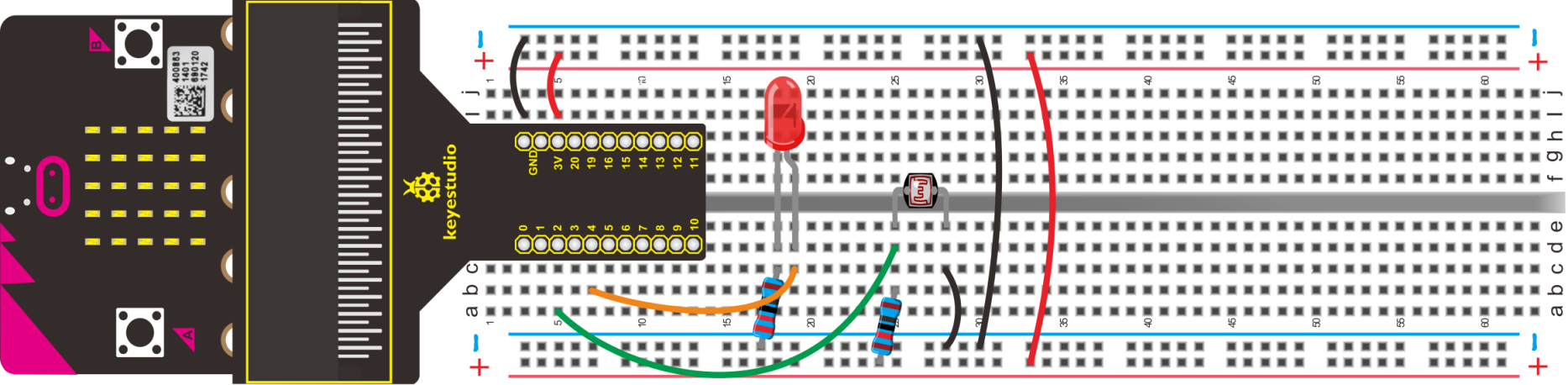

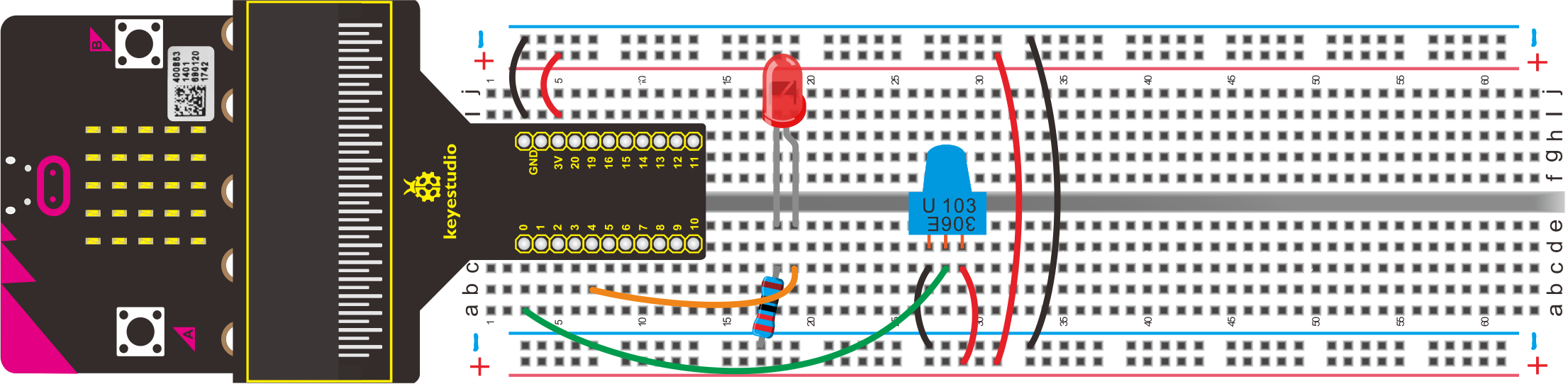

Wiring graph:

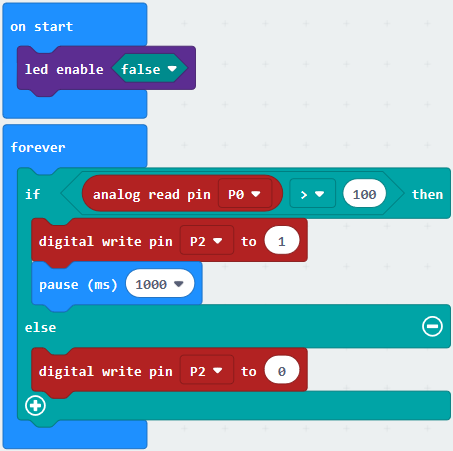

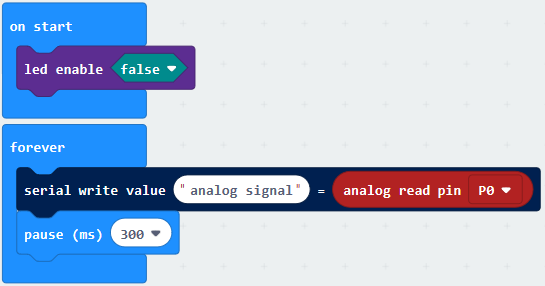

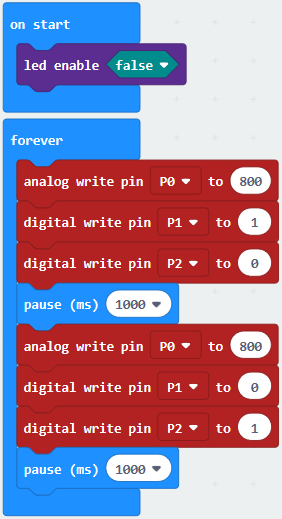

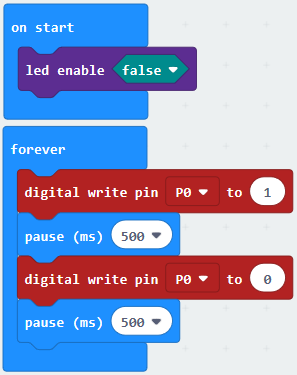

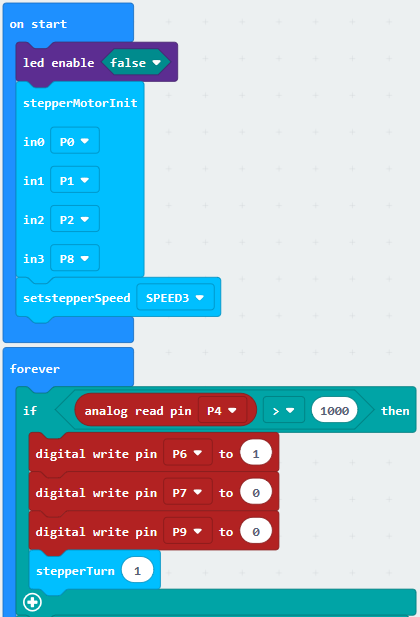

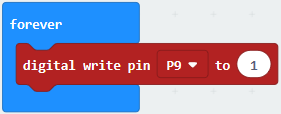

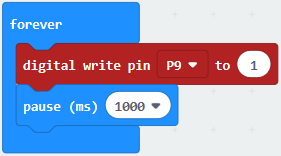

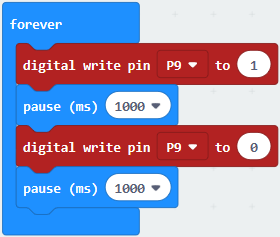

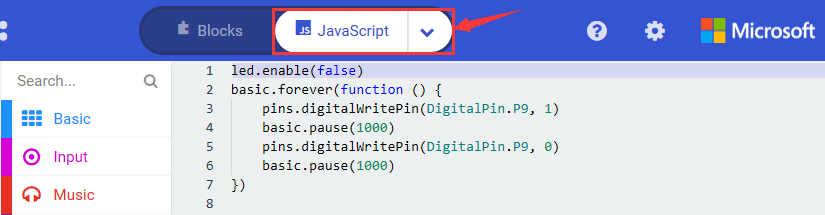

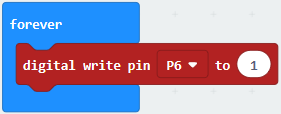

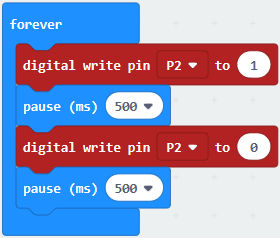

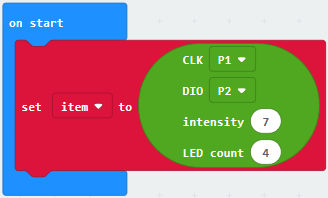

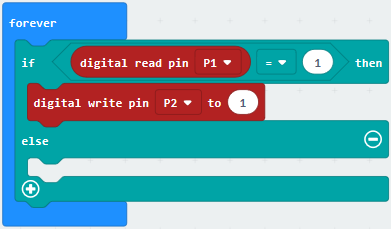

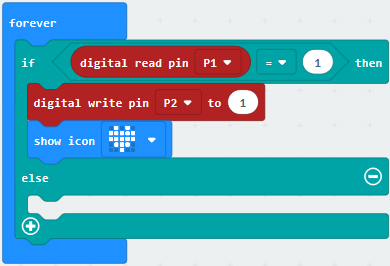

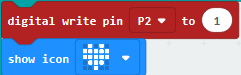

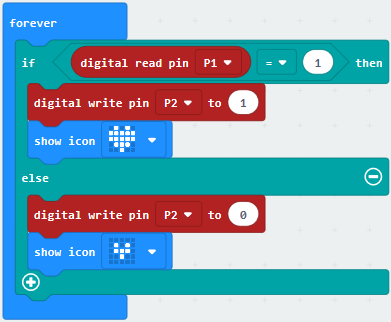

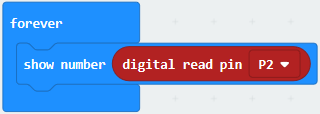

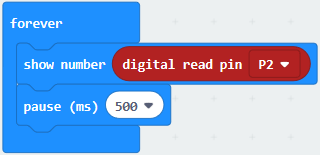

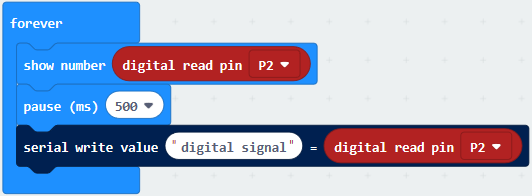

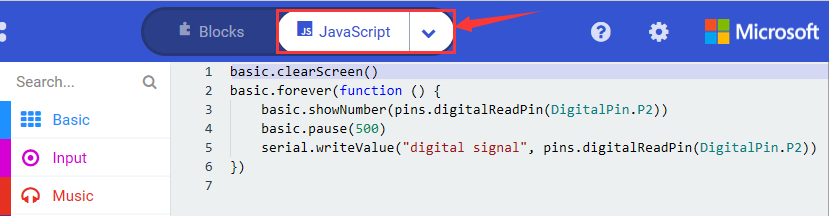

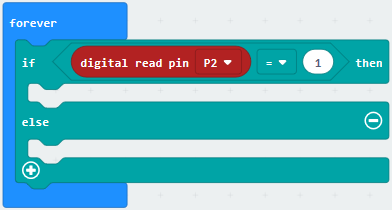

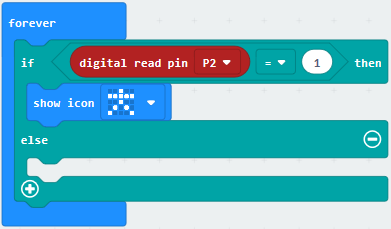

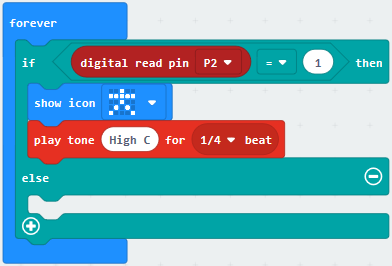

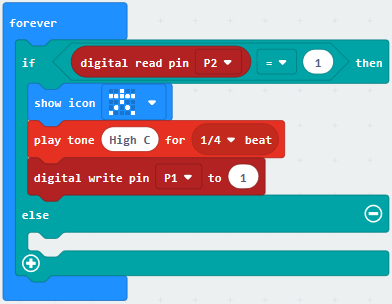

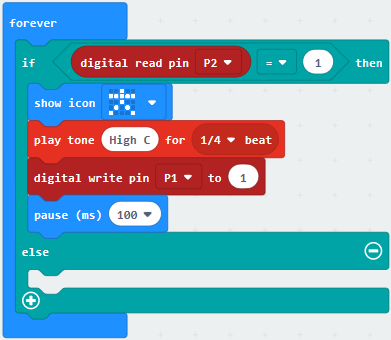

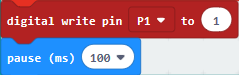

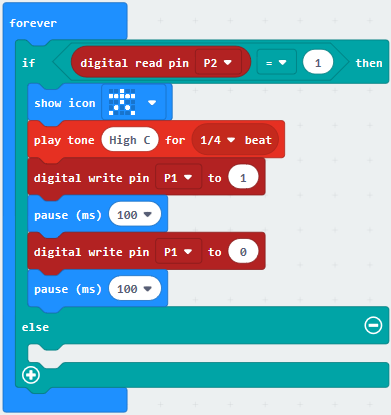

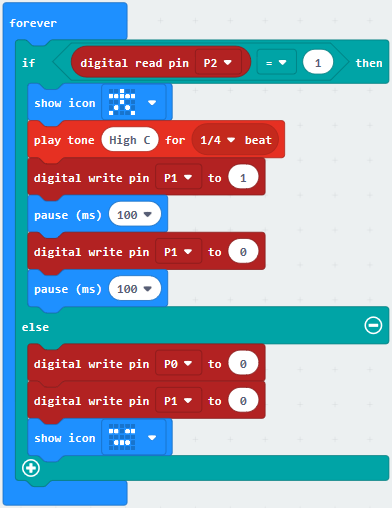

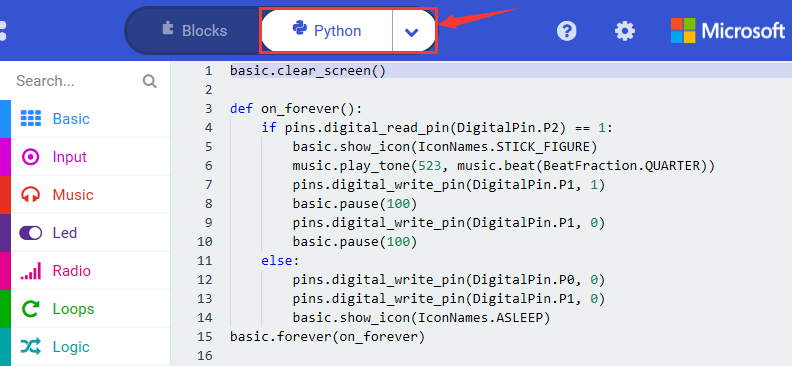

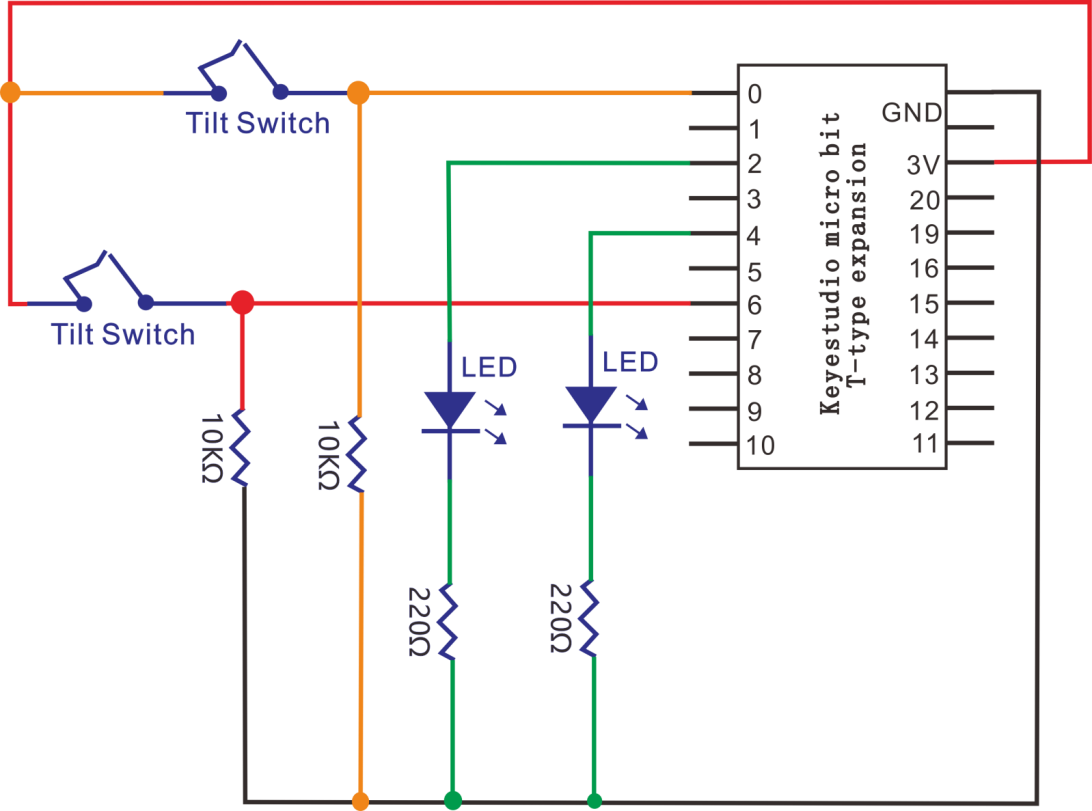

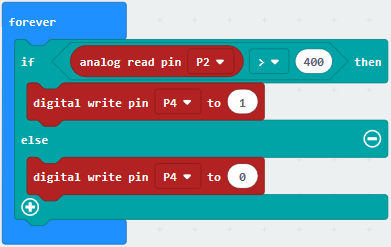

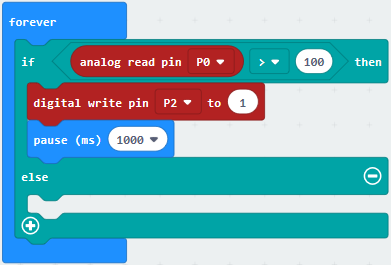

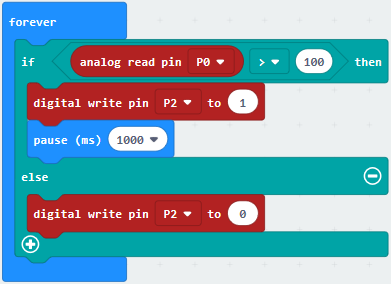

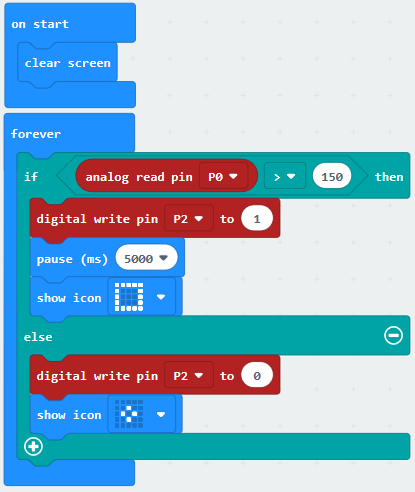

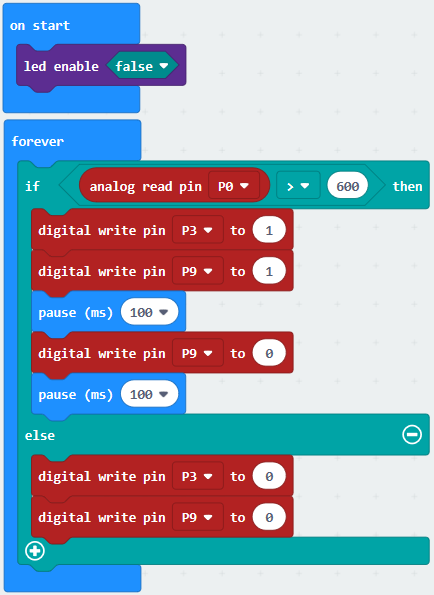

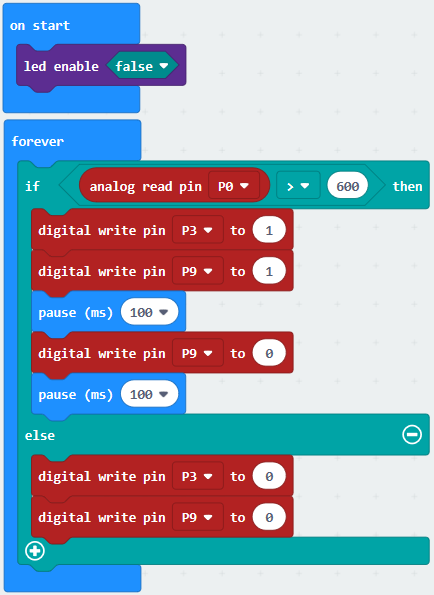

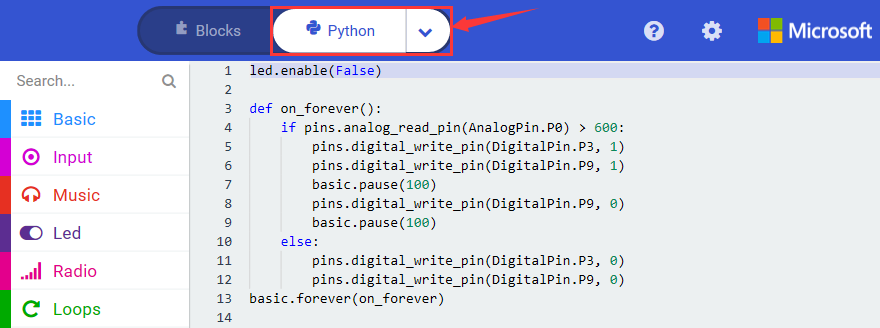

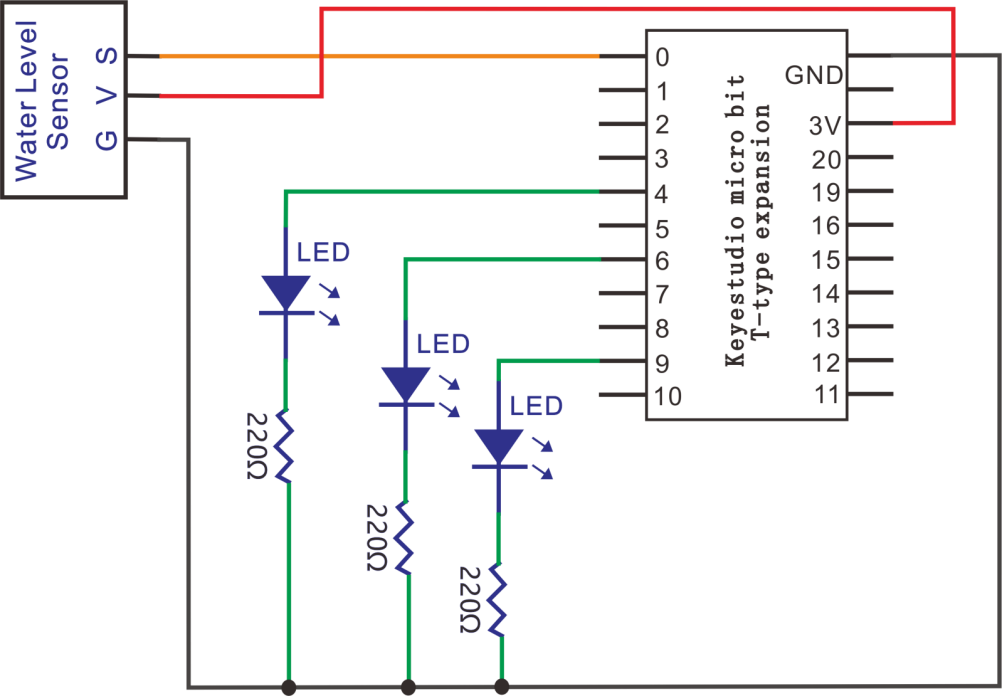

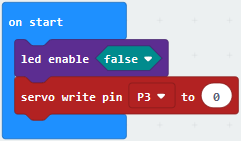

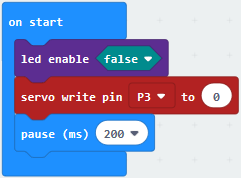

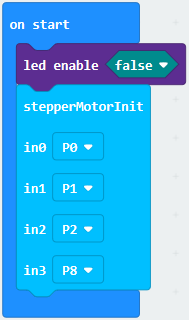

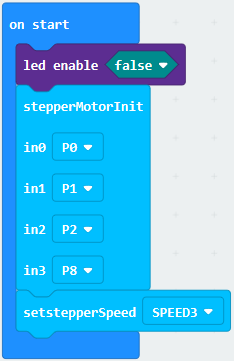

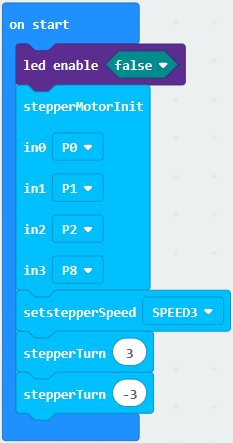

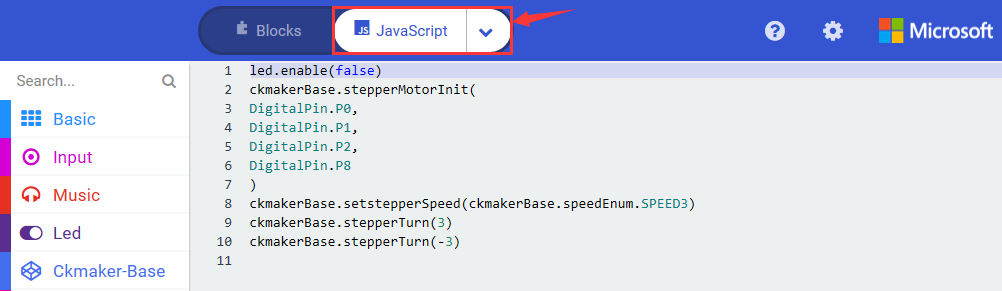

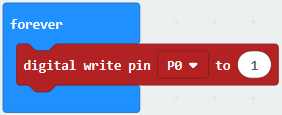

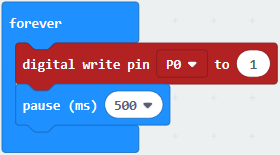

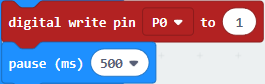

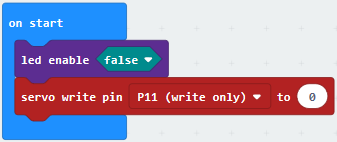

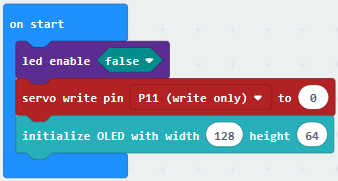

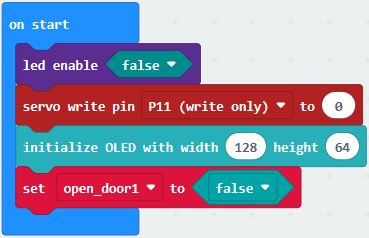

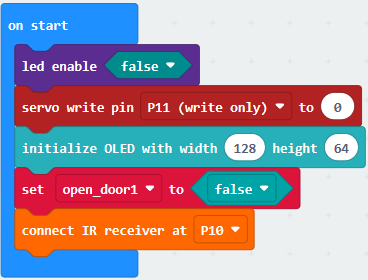

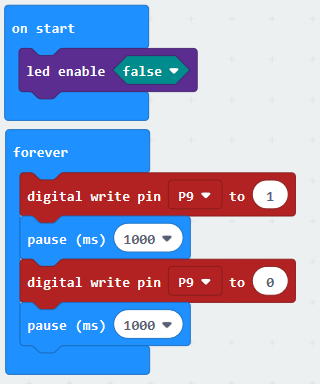

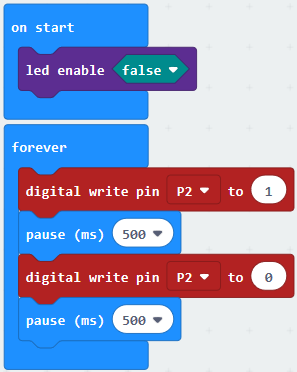

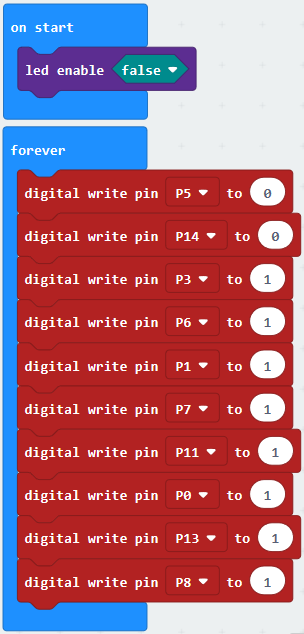

Test Code:

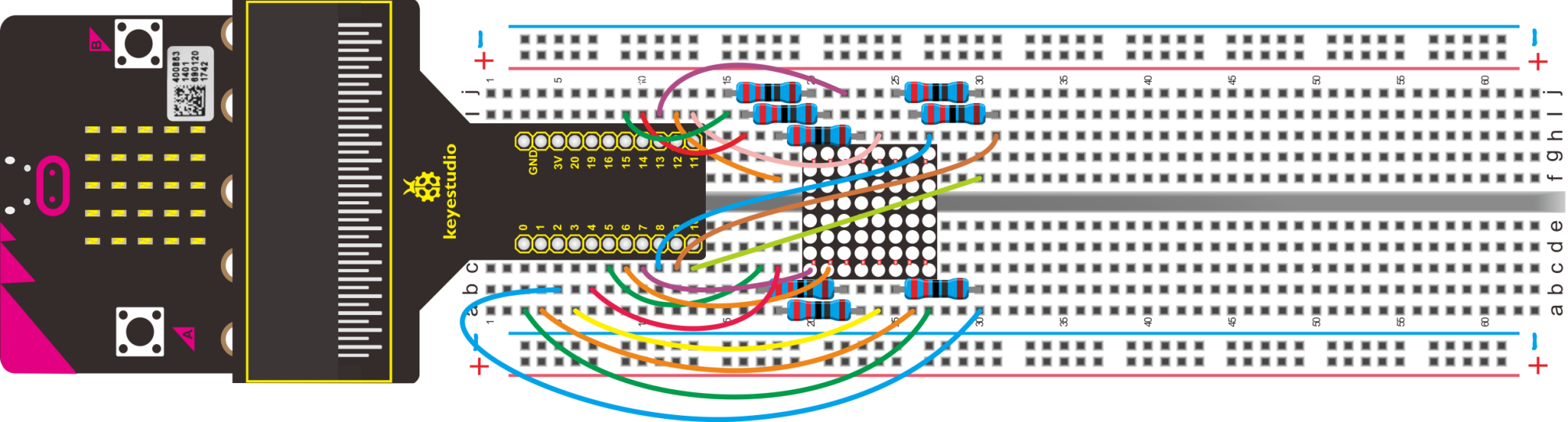

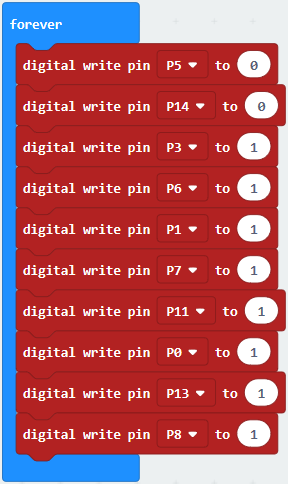

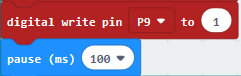

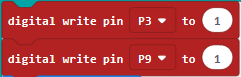

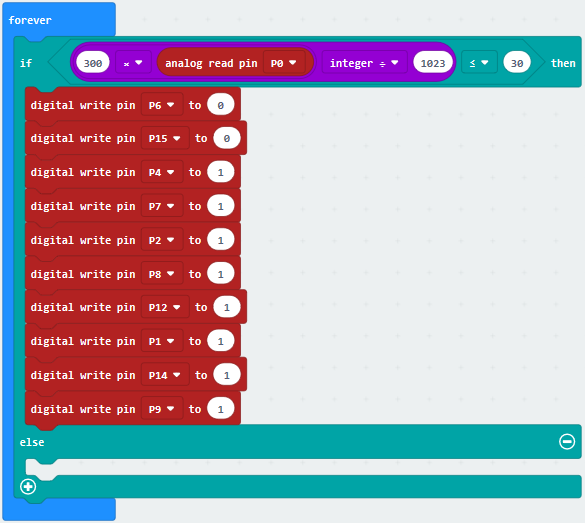

Wire up in the terms of the above graph, LED is linked with P9, and power on.

A. Click“Led”→“more”→“led enable false”;

B. Place it into“on start”block

*****************************************************************

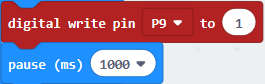

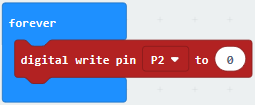

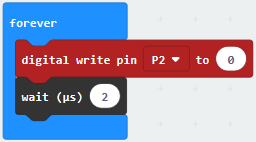

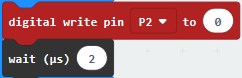

A. Enter“Advanced”→“Pins”,

B. Select“digital write pin P0 to 0”and leave it into“forever”block.

*****************************************************************

Set P9 because LED is attached to P9, and change 0 into 1.

*****************************************************************

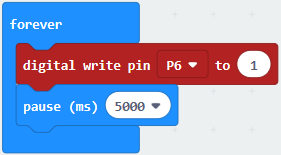

A. Click“Basic”→“pause (ms) 100”;

B. Lay it down into“forever”block and set to 1000ms.

*****************************************************************

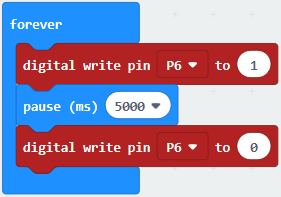

Copy once and alter 1 into 0(turn off LED). Then put it down below the“pause(ms)1000”.

once and alter 1 into 0(turn off LED). Then put it down below the“pause(ms)1000”.

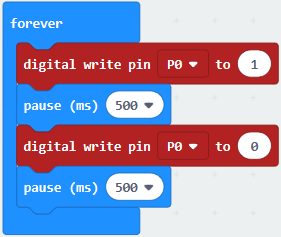

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

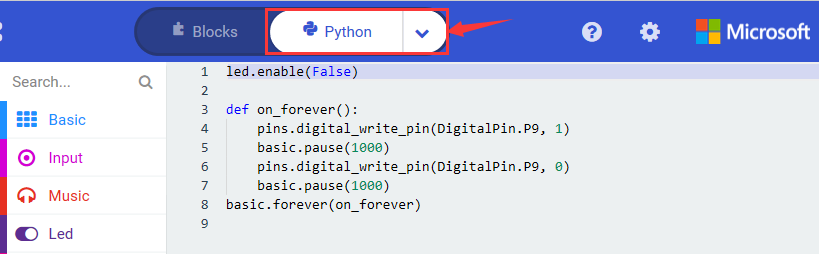

Click“JavaScript”, the corresponding JavaScript code is shown below:

Then click drop-down triangle button and select“Python”to view the Python language code.

Test Results:

Upload code and power on, the external LED flashes at 1s interval.

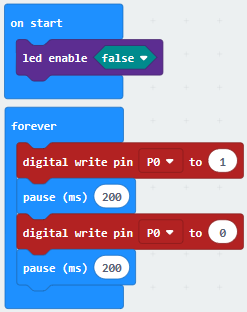

Extension Project:

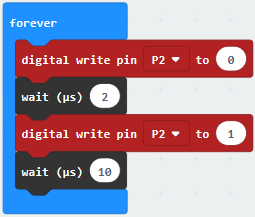

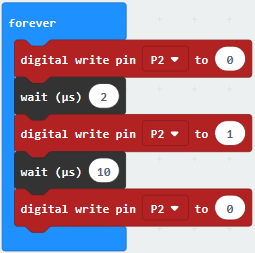

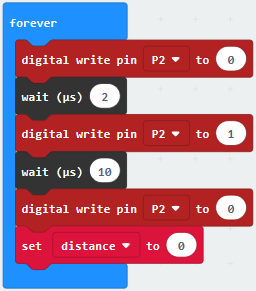

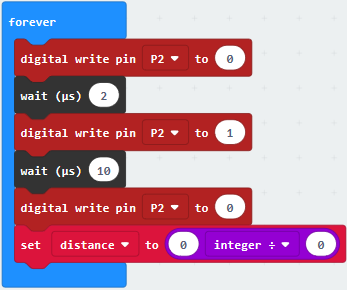

Connect LED to P2 and make LED flicker at 0.5s interval.

Project 14:Traffic Light

Description:

Traffic lights are closely related to people’s daily lives. In the process of learning Micro:bit board, we often use three external red, green and yellow LED circuits to simulate the roadside traffic lights. They traffic light is generally composed of red, yellow, and green (green is blue and green) lights, which is used to govern the traffic.

There are two types of traffic lights, the one is for motor vehicles are called motor vehicle lights. Another one is the pedestrian crossing lights.

When the green light is on, vehicles are allowed to pass. When the yellow light is flashing, which warns that the signal is about to change to red, with some jurisdictions requiring drivers to stop if it is safe to do so, and others allowing drivers to go through the intersection if safe to do so. When the red light is on, vehicles should stop then proceed when safe.

Components List:

Micro:bit Mainboard*1 |

keyestudio Micro:bit T type shield |

Red LED*1 |

Yellow LED*1 |

Green LED*1 |

|---|---|---|---|---|

|

|

|

|

|

220ΩResistor*3 |

Breadboard*1 |

Breadboard wire |

Micro USB cable*1 |

|

|

|

|

|

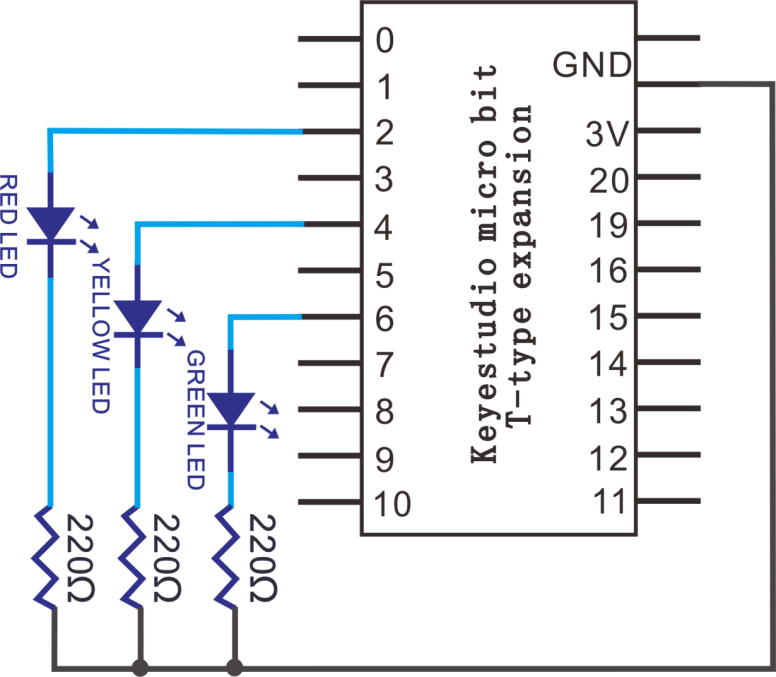

3. Schematic Diagram:

>

>

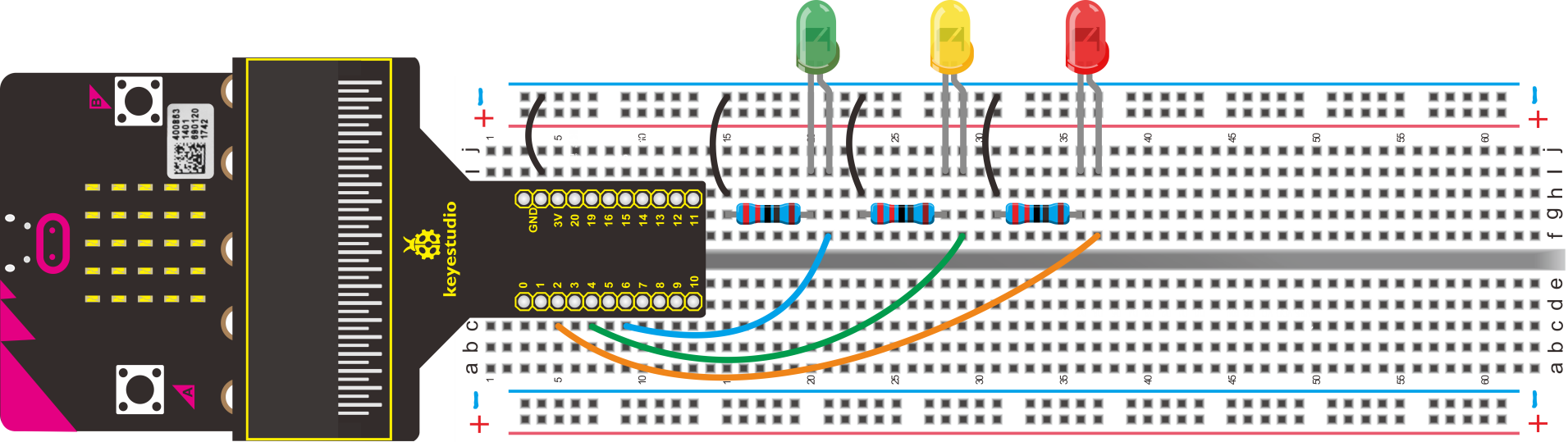

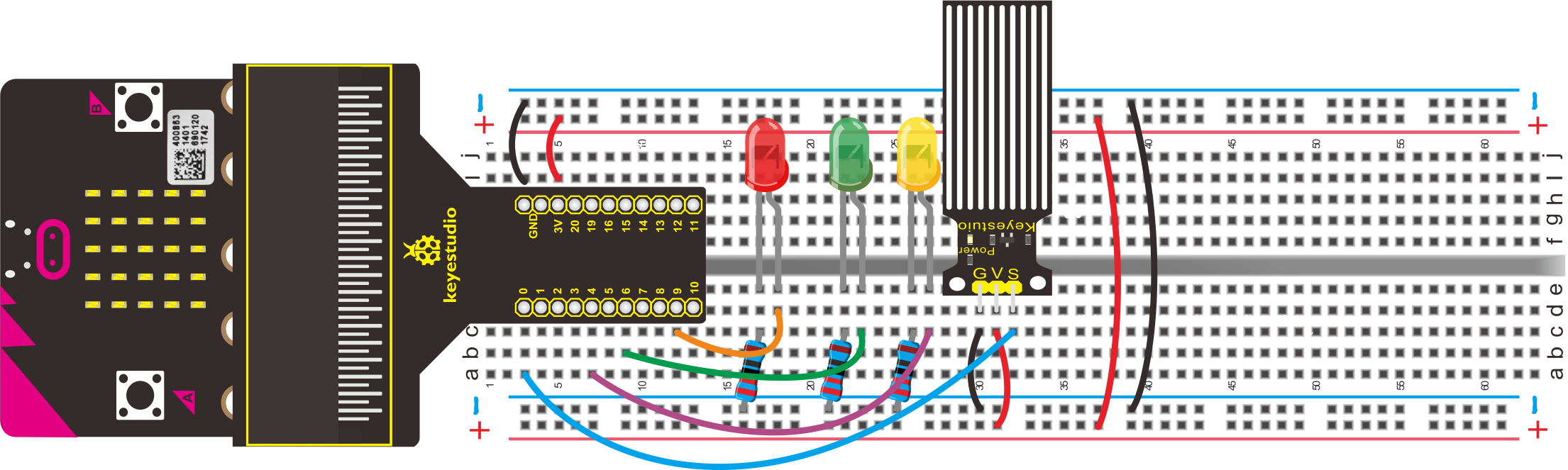

4. Wiring Graph:

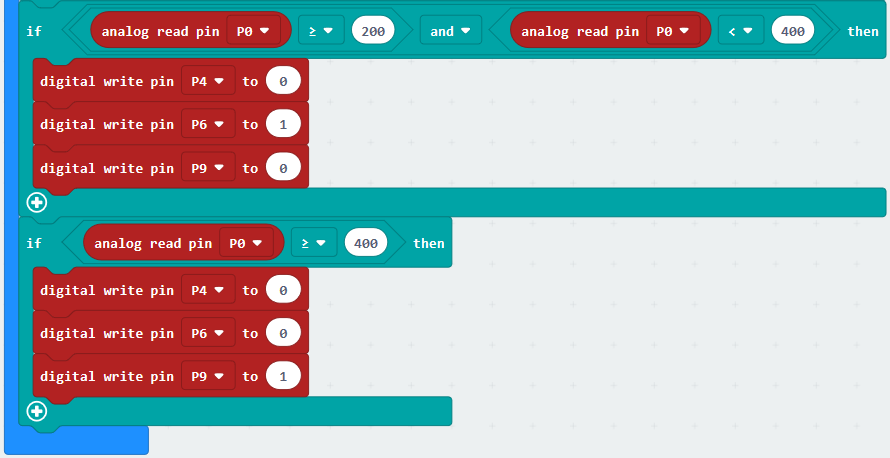

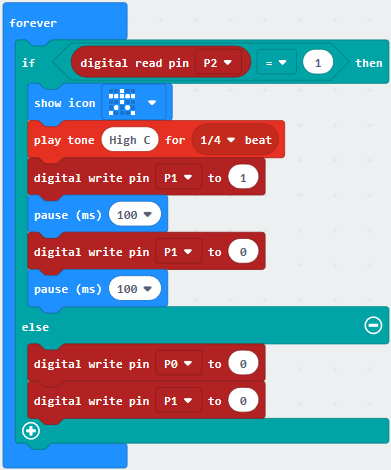

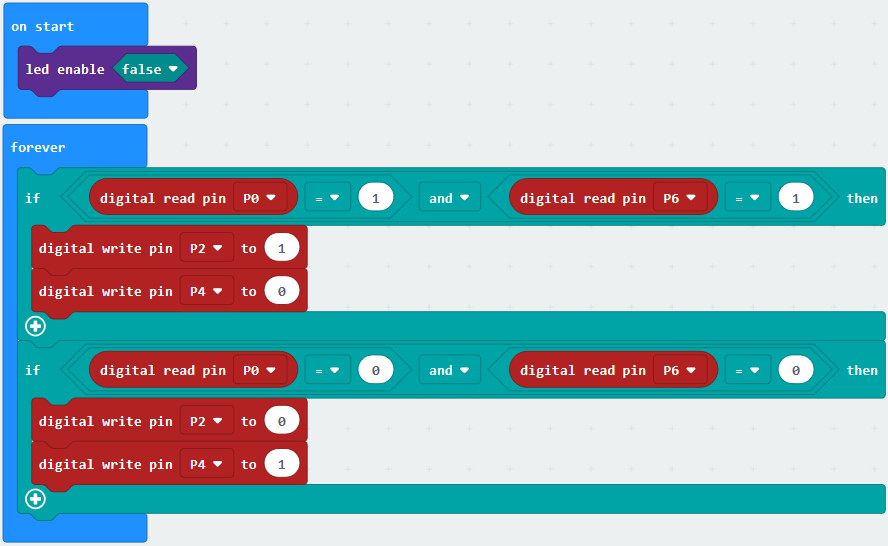

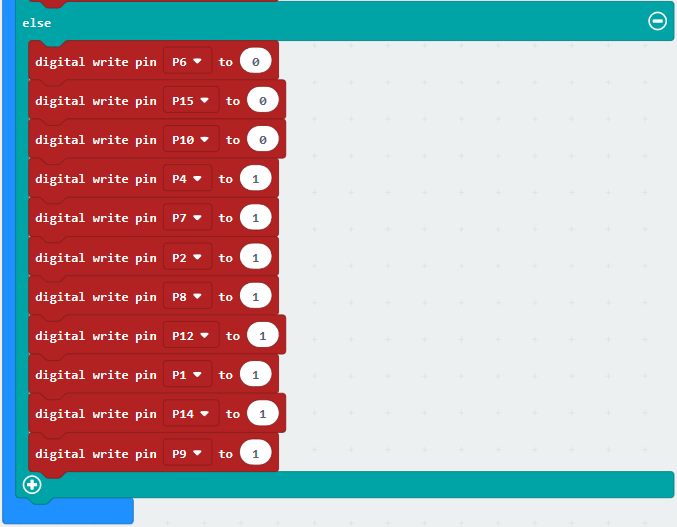

5. Test Code:

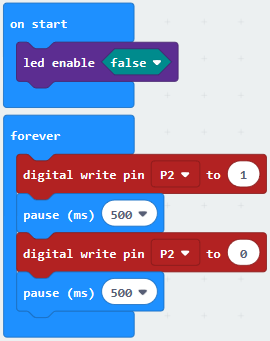

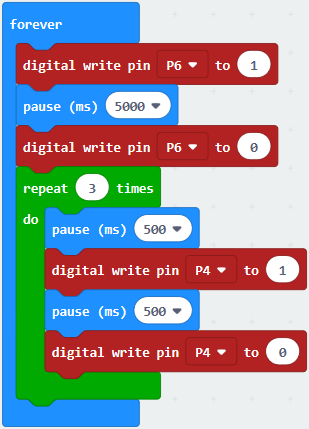

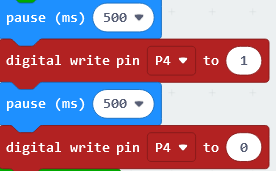

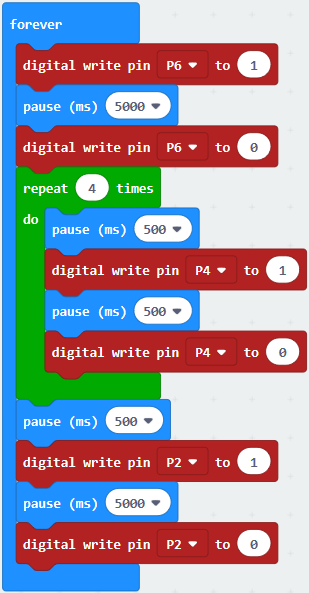

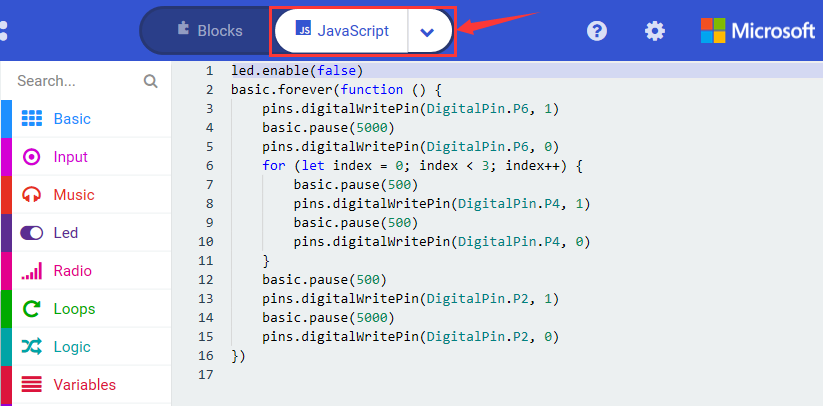

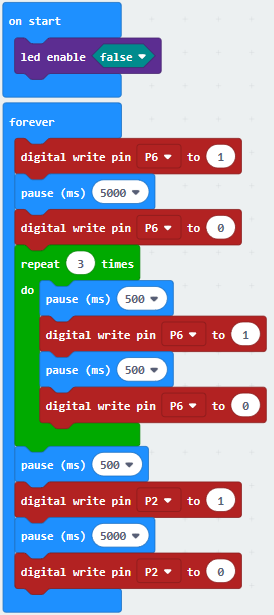

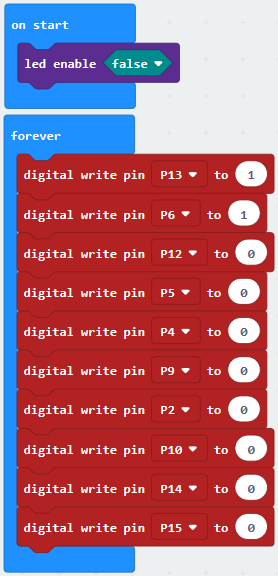

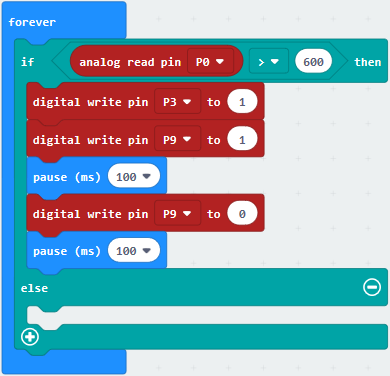

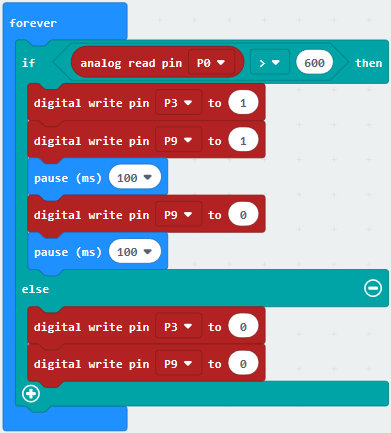

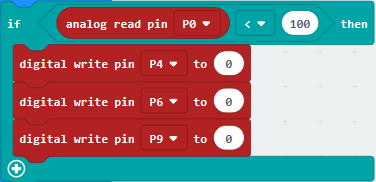

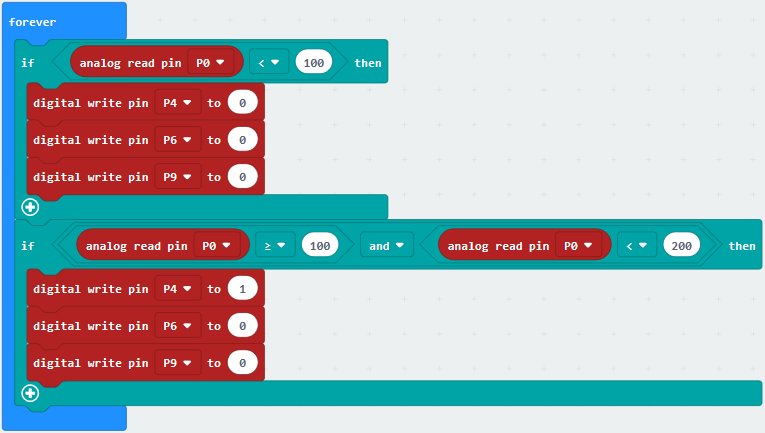

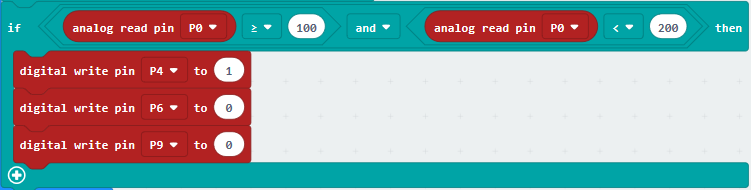

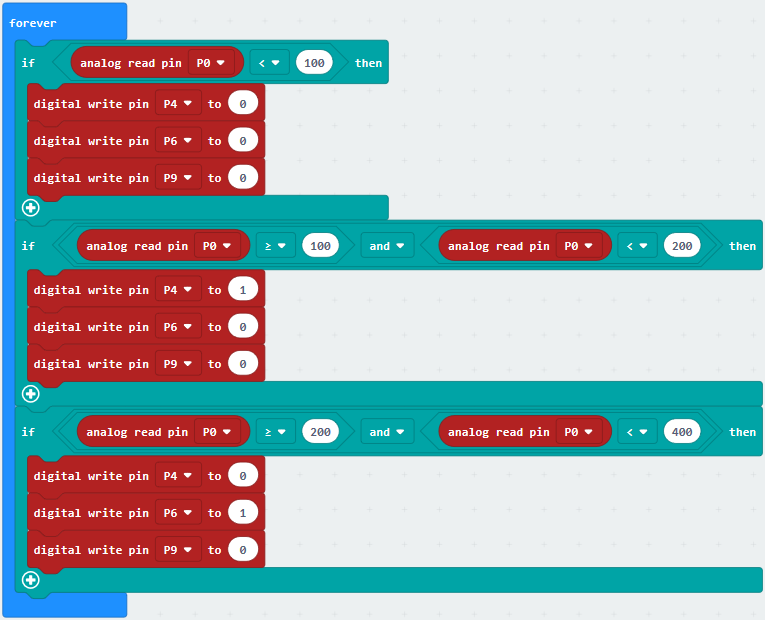

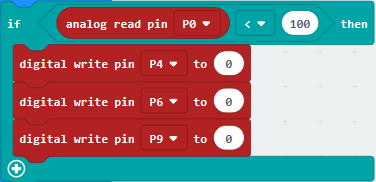

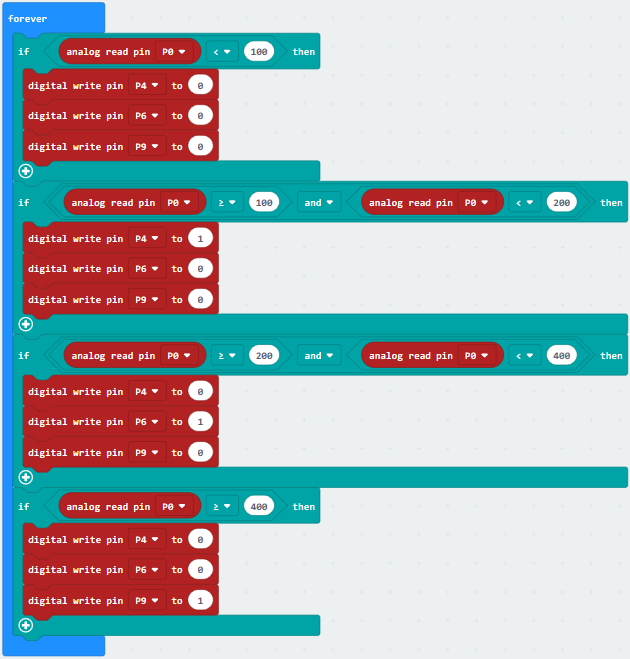

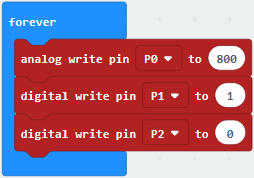

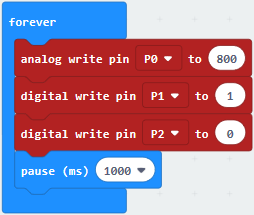

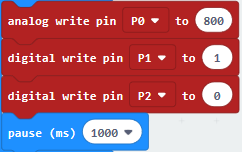

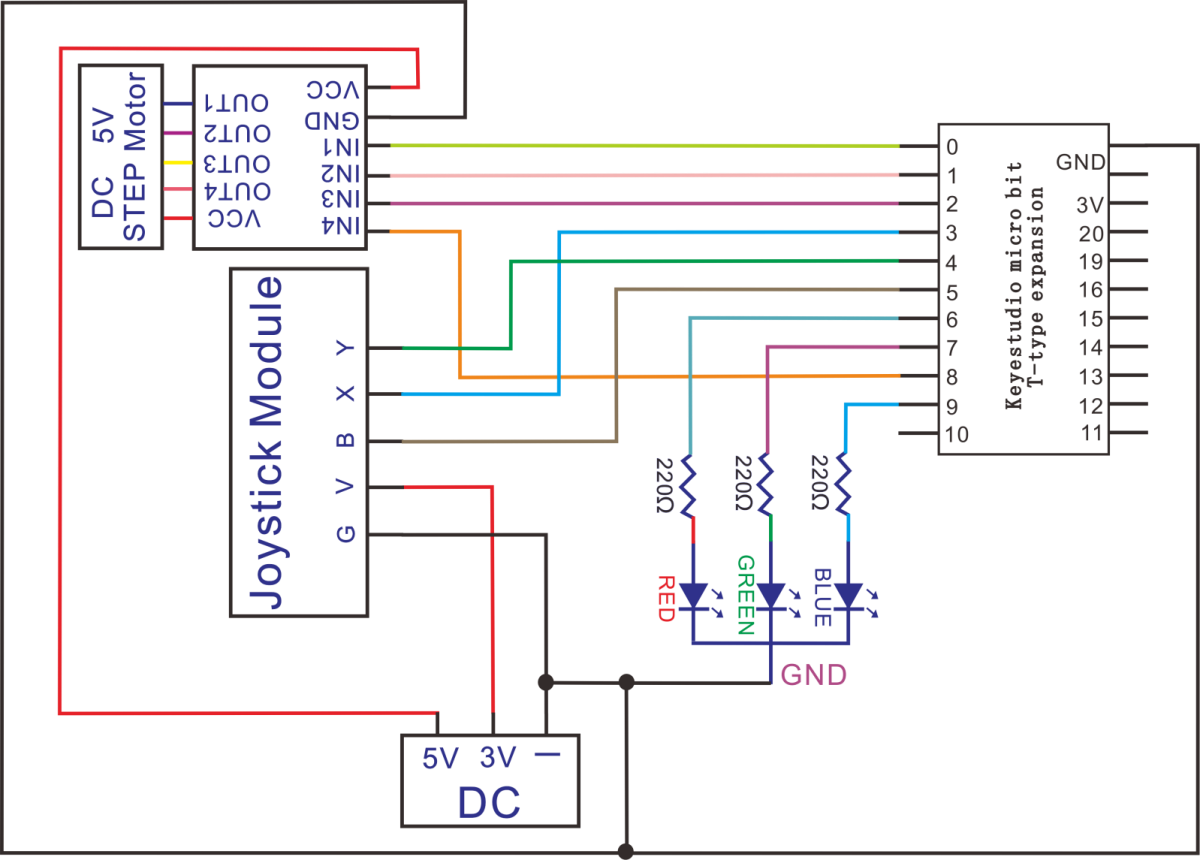

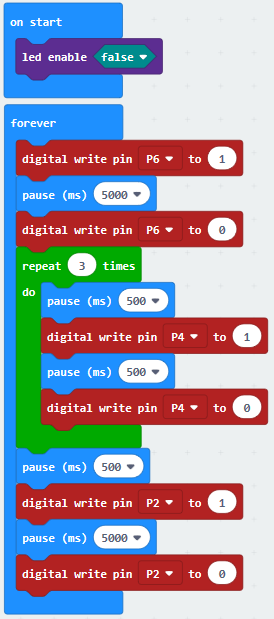

Hook the components up in compliance with the above diagram, separately connect green LED, yellow LED and red LED to P6, P4 and P2.

Click “Led”→”more”→“led enable false”;

Combine it with“on start”.

*****************************************************************

Enter“Advanced”→“Pins”→“digital write pin P0 to 0”into“forever”,and set to“digital write pin P6 to 1”.

*****************************************************************

Go to“Basic”to drag out“pause (ms) 100”into“forever”block set to 500ms.

*****************************************************************

Replicate“digital write pin P6 to 1”once and put it beneath the“pause(ms)5000”block,alter 1 into 0.

*****************************************************************

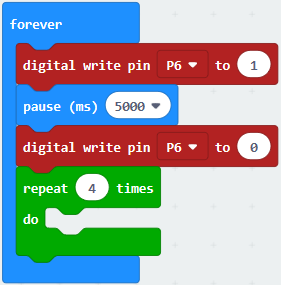

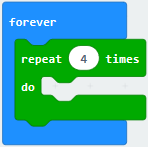

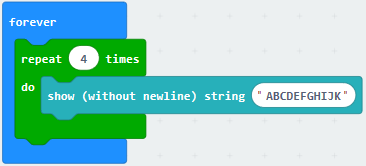

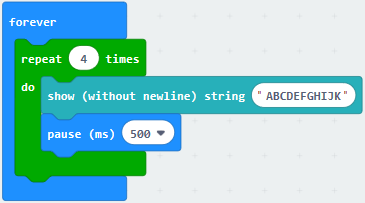

Tap“Loops”to select“repeat 4 times do”and lay it down below the“digital write pin P6 to 0”block :

*****************************************************************

Duplicate“pause (ms)5000”and

once again and keep them into“repeat 4 times do”. Yellow LED is linked with P4 and blinks 3 times, so set code string as follows:

*****************************************************************

Copy  code string once, and set to P2, change the last 500 into 5000.

code string once, and set to P2, change the last 500 into 5000.

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

Click“JavaScript” to check the corresponding JavaScript code:

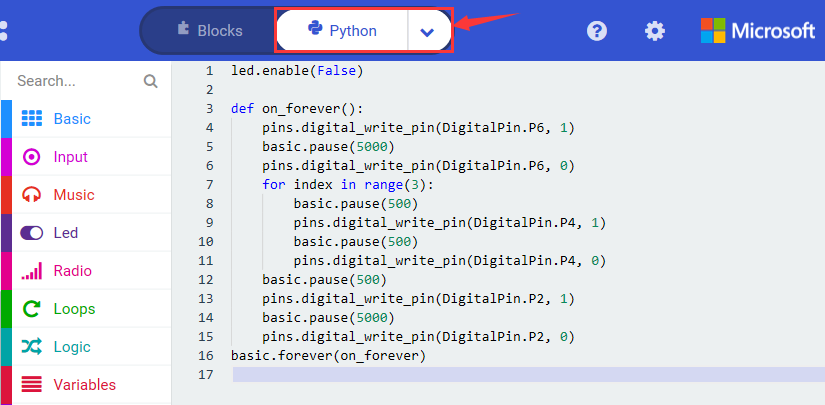

Then click drop-down triangle button and select“Python”to see the Python language code:

Test Results:

Upload code and power on, the green LED is on for 5s then goes off, next, yellow LED blinks for 3 times and red LED lights up for 5s then goes off, cyclically.

Extension Project:

Simulate the traffic light, make green LED light up for 5s, then flicker for 3s and finally light on red LED.

Project 15:Flow Light

Description:

Flow light, also called advertisement lights, emits light like flowing water.

In this project, we just need to add more LEDs and control the order and time to perform the phenomenon of flow light.

Component List:

Micro:bit Main board*1 |

keyestudio Micro:bit T Type Shield |

Red LED*6 |

Micro USB cable*1 |

|---|---|---|---|

|

|

|

|

220Ω Resistor*6 |

Breadboard*1 |

Breadboard wires |

|

|

|

|

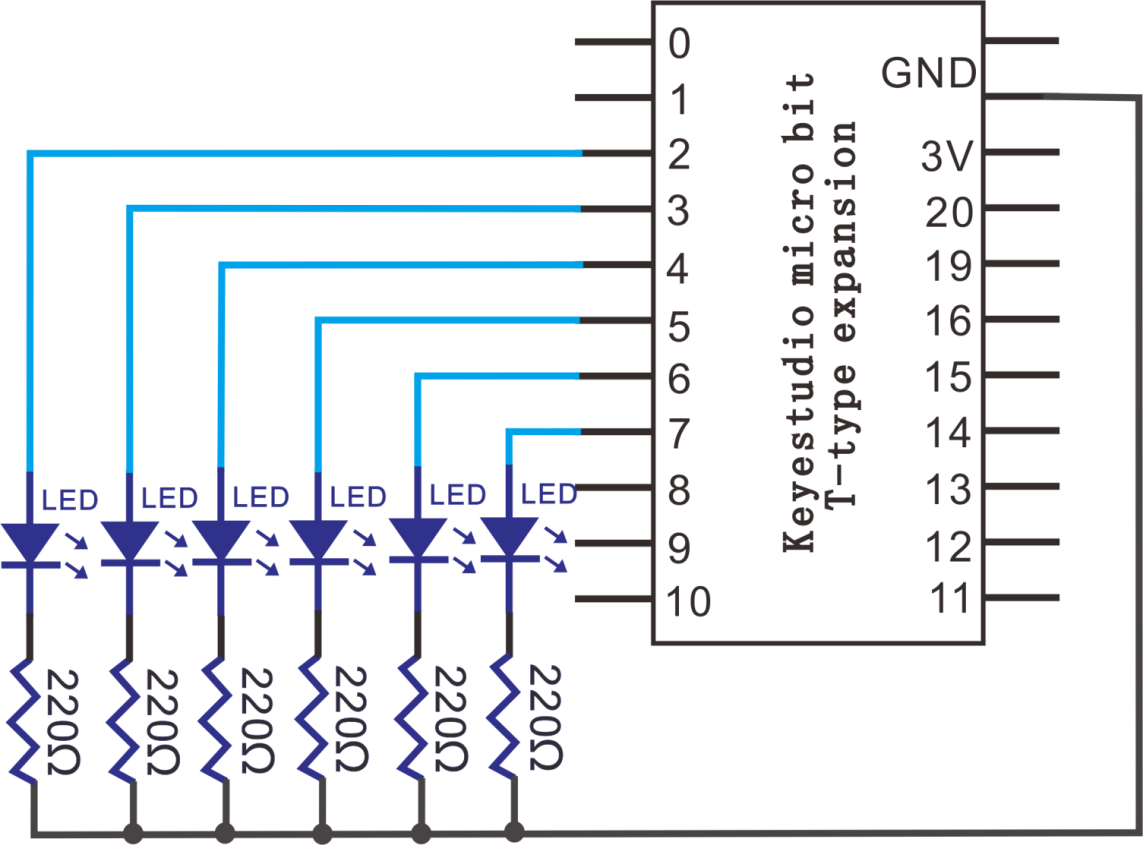

Schematic Diagram:

>

>

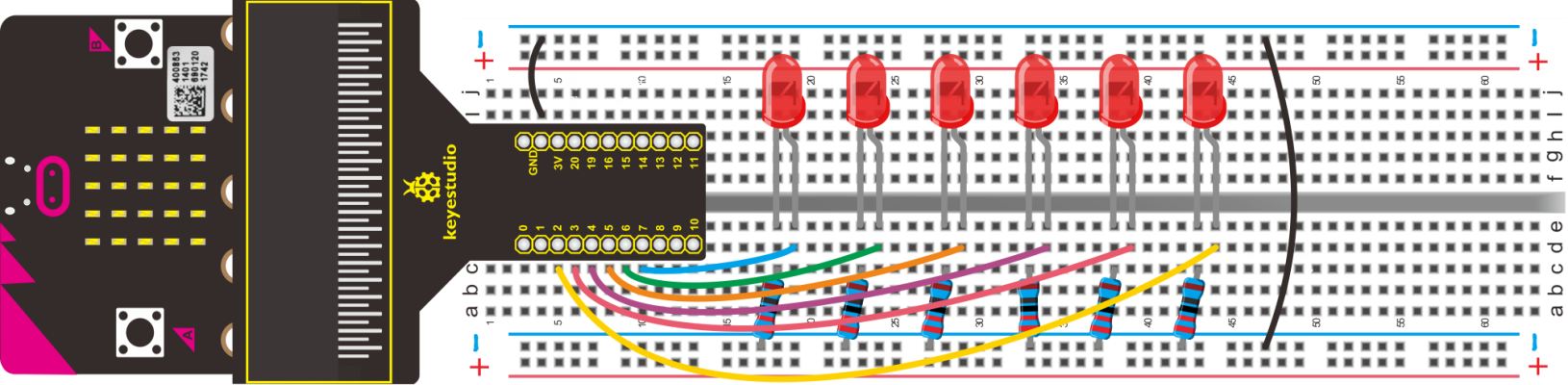

Wiring Graph:

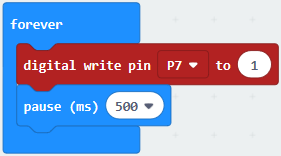

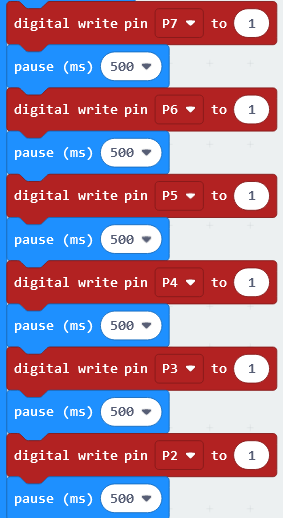

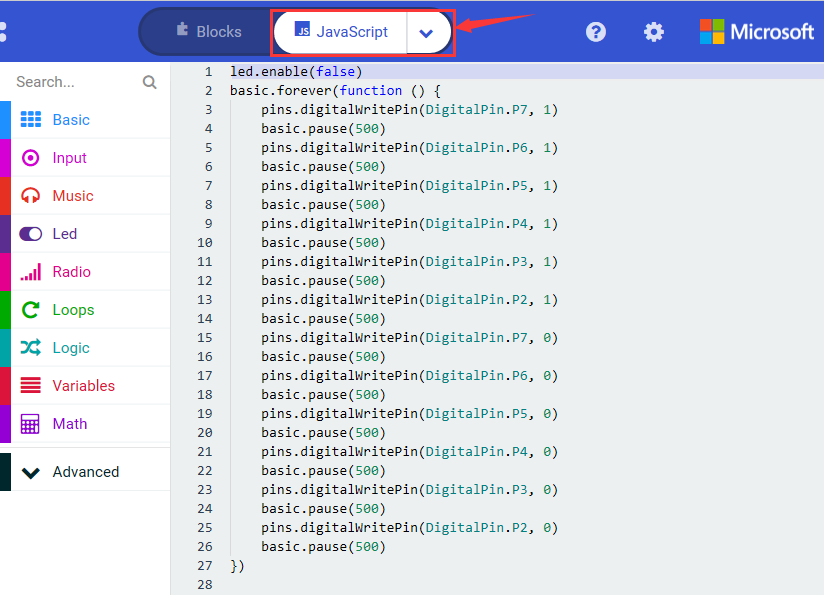

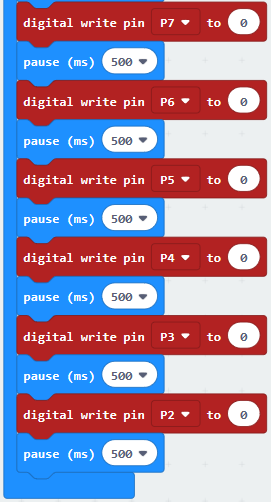

5. Test Code:

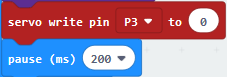

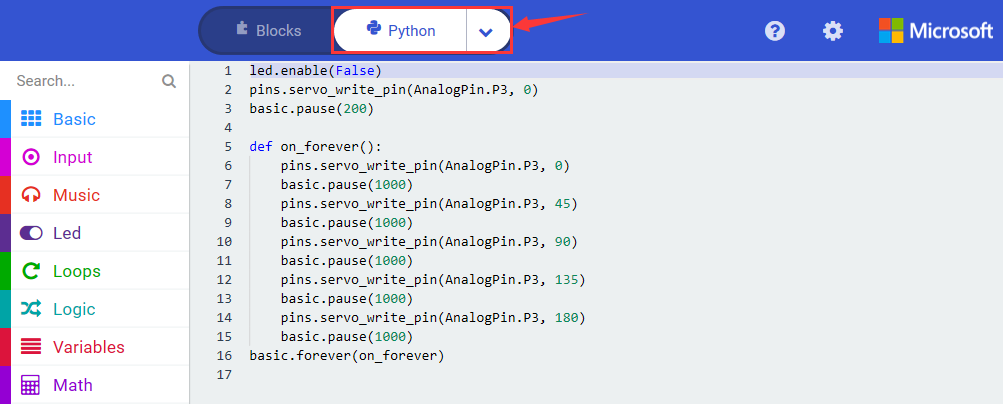

According to the above graph, 6 red LEDs are respectively attached to P2, P3, P4, P5, P6 and P7, enter Micro: bit online programming too to design code:

Click “Led”→”more”→“led enable false”;

Combine it with “on start”

*****************************************************************

A. Enter “Advanced”→“Pins”→“digital write pin P0 to 0”

B. Drag it into“forever”and set to “digital…P7 …to 1”.

*****************************************************************

Go to“Basic”to drag out“pause (ms) 100”below the block digital…P7 …to 1”, then set to 500ms.

*****************************************************************

Copy code string for 5 times and, put it down into“forever”,separately set to P6, P5, P4, P3 and P2.

for 5 times and, put it down into“forever”,separately set to P6, P5, P4, P3 and P2.

Then duplicate code string once, change 1 into 0.

once, change 1 into 0.

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

Click “JavaScript” to look through the corresponding JavaScript code:

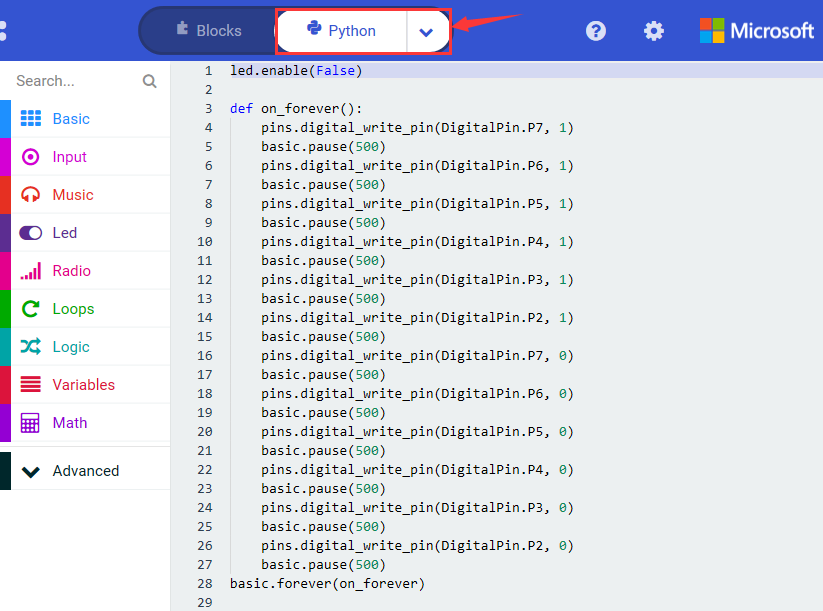

Then click the triangle button and select“Python”and check the Python language code:

Test Results:

Upload code and power on, the external LED lights up one by one, then gets dark orderly.

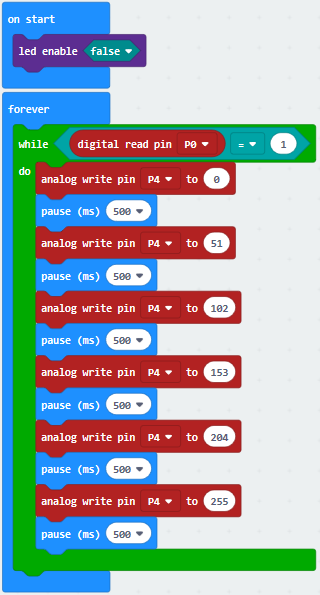

Project 16:Breathing Light

Description:

In the previous lesson, we control LEDs on and off and make them blink.

In this project, we will control LED brightness through PWM to simulate breathing effect. Similarly, you can change the step length and delay time in the code so as to demonstrate different breathing effect.

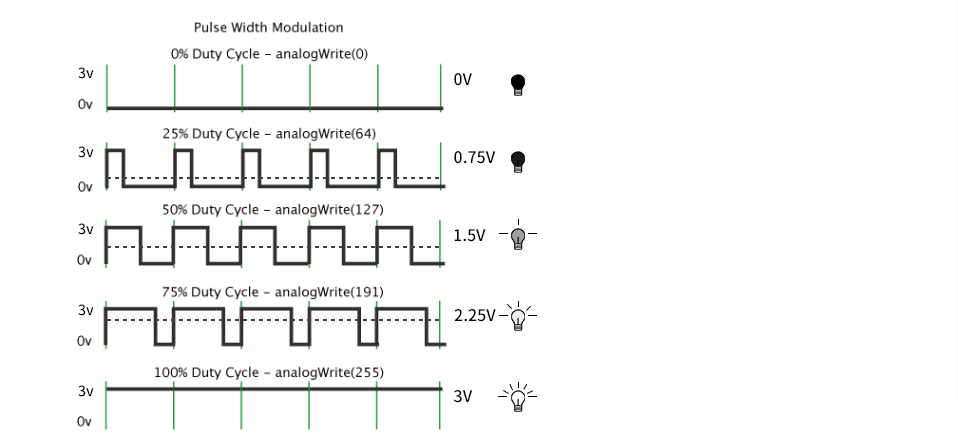

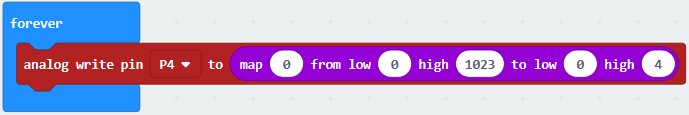

PWM is a means of controlling the analog output via digital means. Digital control is used to generate square waves with different duty cycles (a signal that constantly switches between high and low levels) to control the analog output.

In general, the input voltage of port are 0V and 5V. What if the 3V is required? Or what if switch among 1V, 3V and 3.5V? We can’t change resistor constantly. For this situation, we need to control by PWM.

For the Arduino digital port voltage output, there are only LOW and HIGH, which correspond to the voltage output of 0V and 5V. You can define LOW as 0 and HIGH as 1, and let the Arduino output five hundred 0 or 1 signals within 1 second.

If output five hundred 1, that is 5V; if all of which is 1, that is 0V. If output 010101010101 in this way then the output port is 2.5V, which is like showing movie. The movie we watch are not completely continuous. It actually outputs 25 pictures per second. In this case, the human can’t tell it, neither does PWM. If want different voltage, need to control the ratio of 0 and 1. The more 0,1 signals output per unit time, the more accurately control.

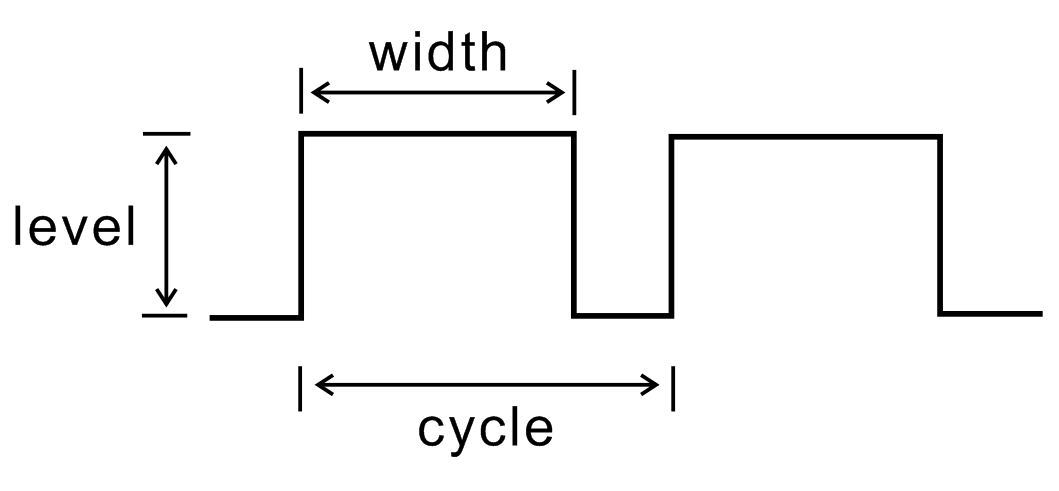

Pulse width modulation (PWM) has many applications: lamp brightness adjustment, motor speed adjustment, sound generation, etc. The following are the three basic parameters of PMW:

>

>

(1) Amplitude of pulse width (minimum/maximum)

(2) Pulse period (the reciprocal of pulse frequency within 1 second)

(3) Voltage level (for example: 0V-3V)

(4) Micro: There are 6 PMW interfaces , namely digital pins P0, P1, P2, P3, P4 and P10.

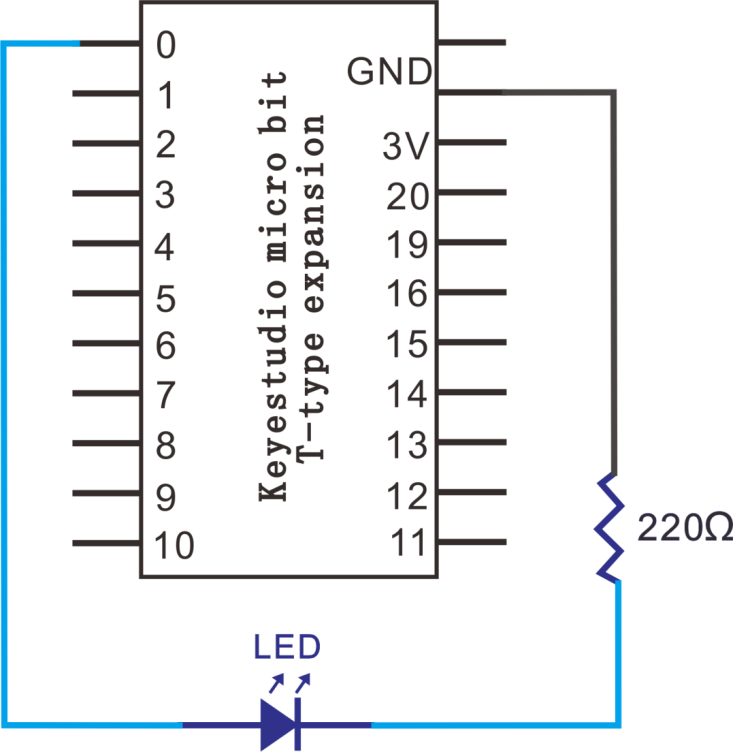

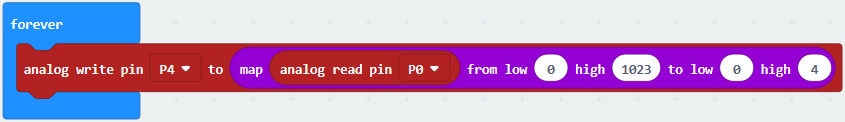

In this program, we connect red LED to P0 of micro:bit motherboard. And P0 can be input port as well. We could control LED brightness through P0 port. The LED will get bright gradually then dark, alternately, which looks like human breath.

Components List:

Micro:bit Main board*1 |

keyestudio Micro:bit T type shield |

Red LED*1 |

Breadboard wire |

|---|---|---|---|

|

|

|

|

220Ω Resistor*1 |

Breadboard*1 |

Micro USB cable*1 |

|

|

|

|

Schematic Diagram:

>

>

Wiring Graph:

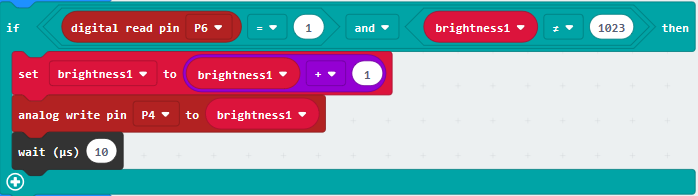

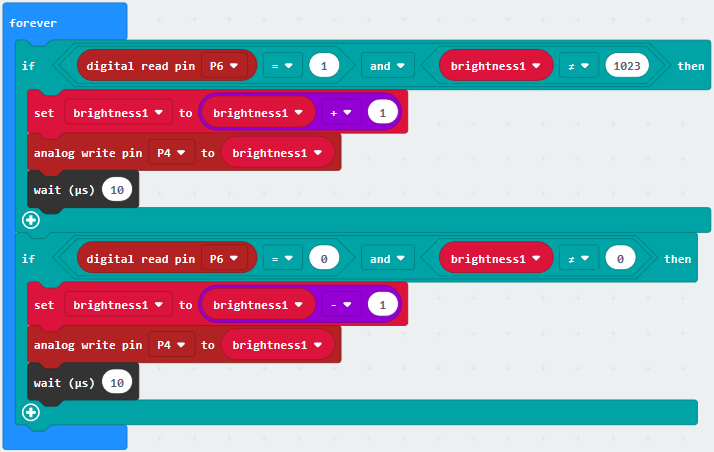

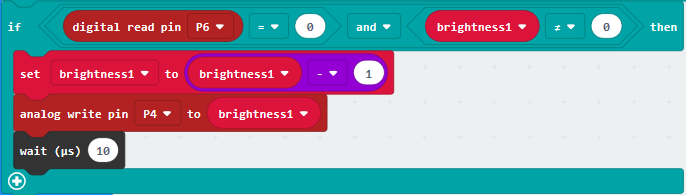

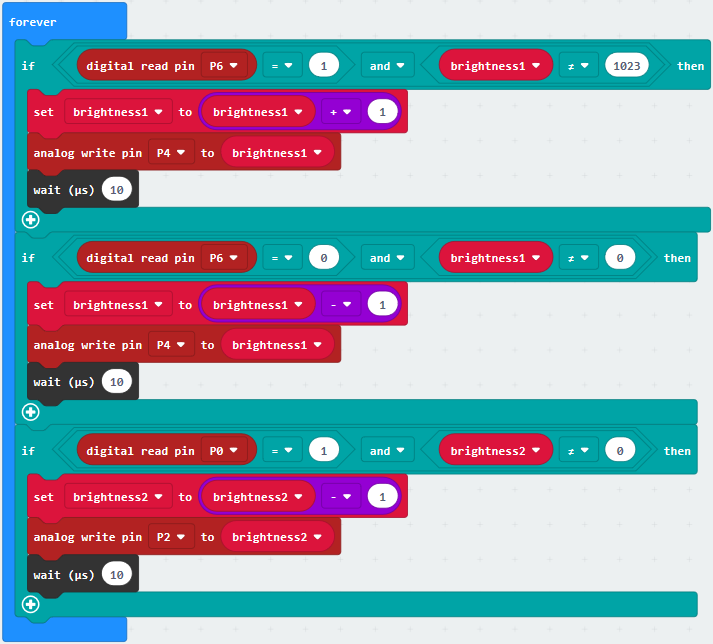

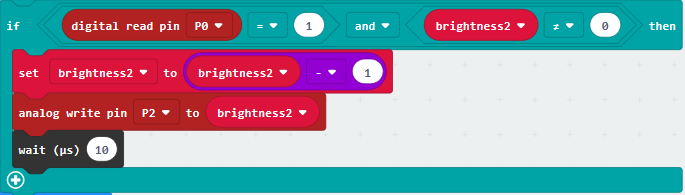

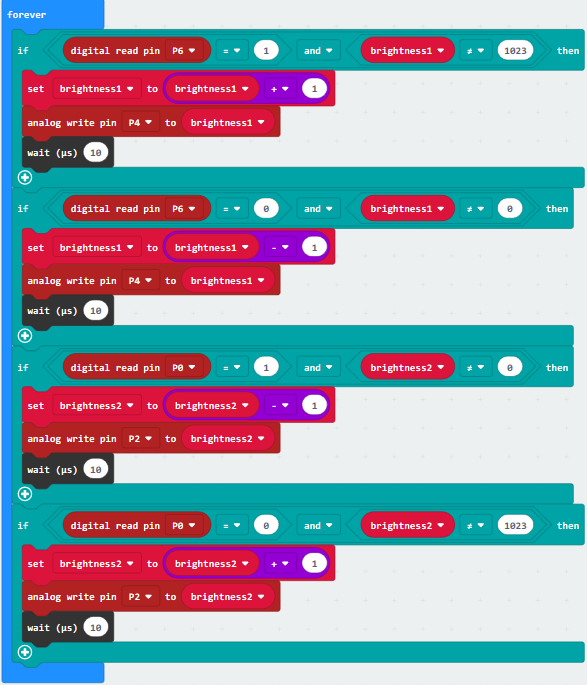

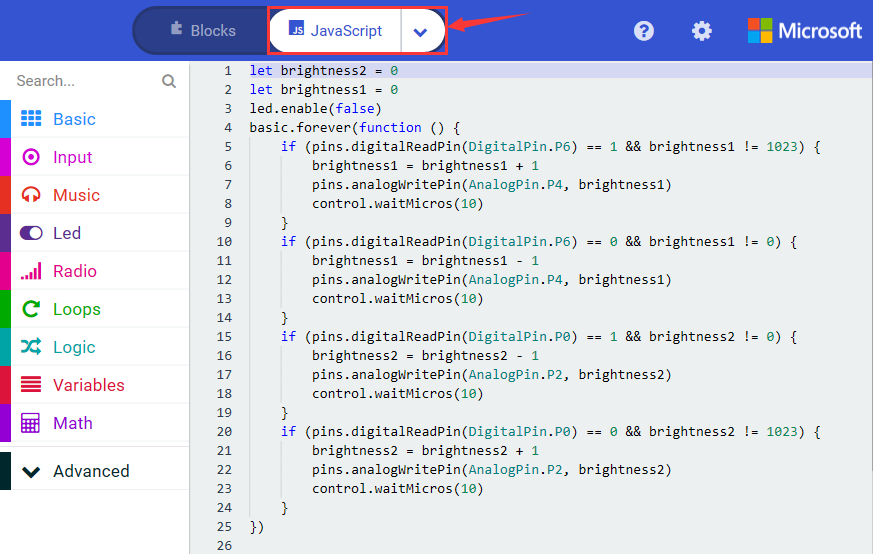

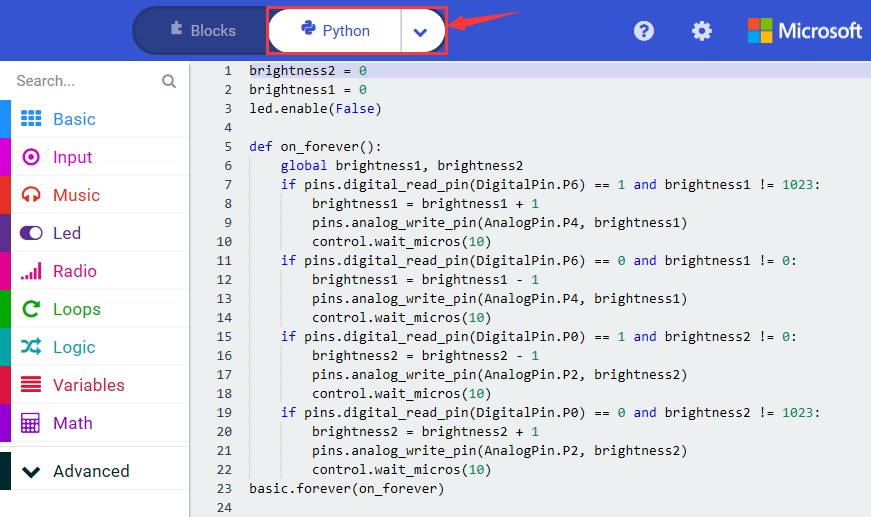

5. Test Code:

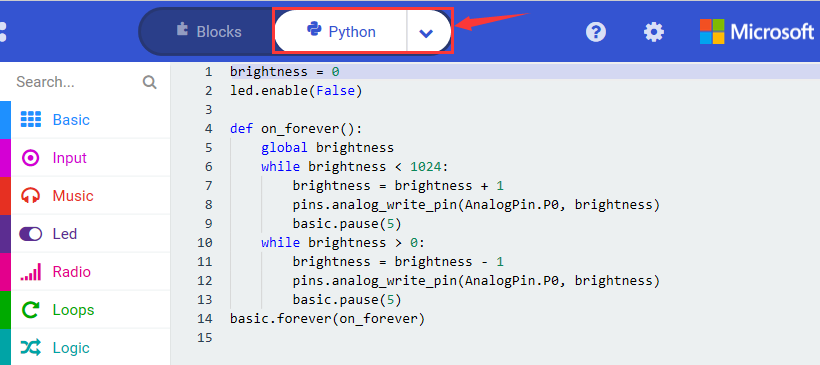

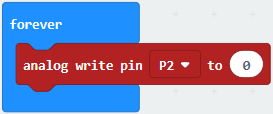

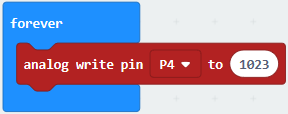

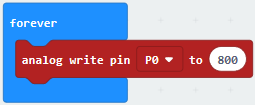

From the above diagram, LED is connected to P0. Open the Micro:bit online programming tool.

(1)A. Click “Led”→”more”→“led enable false”;

B. Combine it with“on start”.

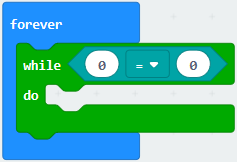

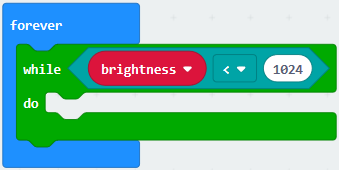

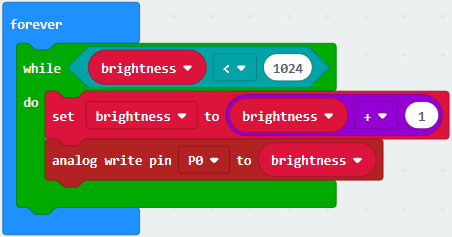

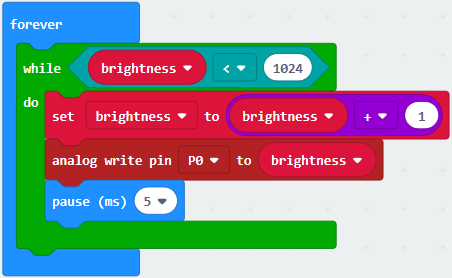

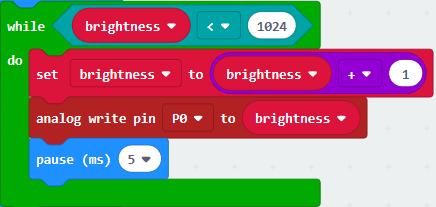

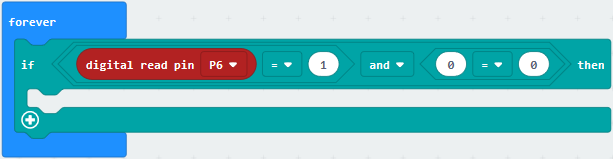

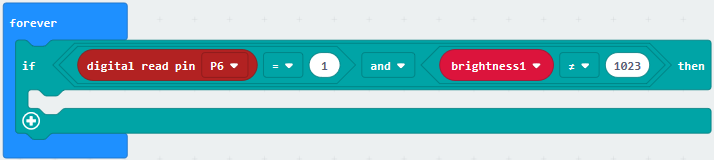

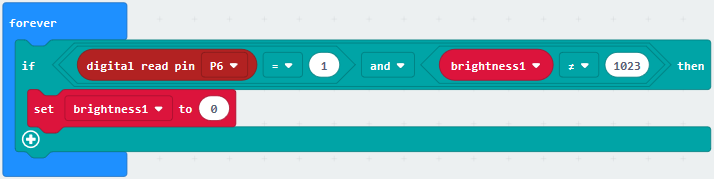

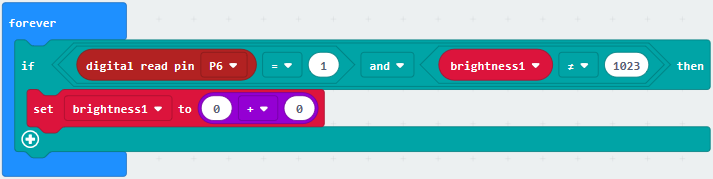

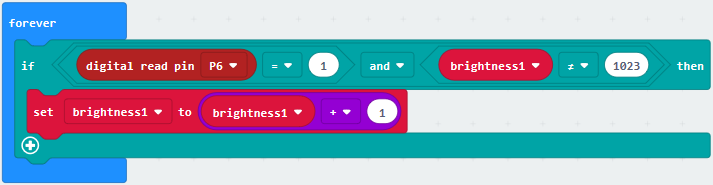

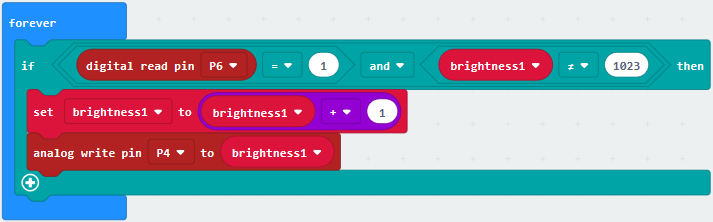

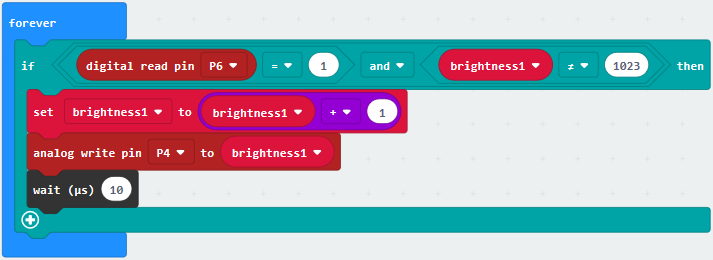

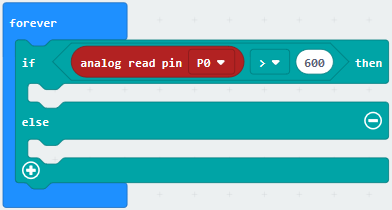

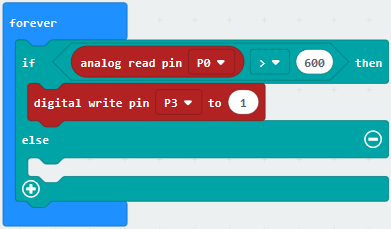

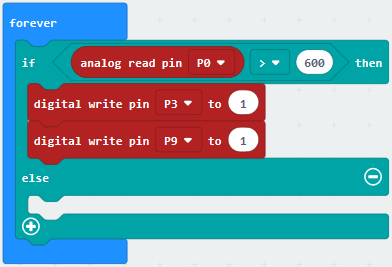

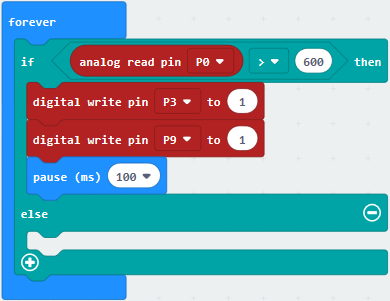

(2) Go to“Loops”to move “while…true…do”into block“forever”. Then click“Logic”to drag“=”into“true”box.

*****************************************************************

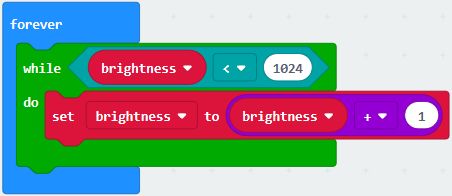

(3) Click “Variables”→“Make a Variable…”→“New variable name:”box,input“brightness”in dialog box and tick“OK”,then the variable“brightness”is produced. Lay down“brightness”to the left box of “=”,change “0”into “1024”,“=”into“<”.

*****************************************************************

(4) A. Follow the above method to create variable“set brightness to 0”, and put it down into“do”block.

B. Enter“Math”to get“+”block and move it into“0” box ,

C. Move out variable“brightness”again into the left“0” box of block “+”, then alter 0 into 1.

*****************************************************************

(5) A. Go to“Advanced”→“Pins”→“analog write pin P0 to 1023”;

B. Keep it beneath the“set…brightness…1”block, then replace 1023 with“brightness”.

*****************************************************************

Go to “Basic” to drag out “pause (ms) 100”into“while…do”block set to 5ms.

*****************************************************************

Copy the code string once and place it into “do” block. Change“<”into“>”, 1024 into 0,“+”into“-”.

once and place it into “do” block. Change“<”into“>”, 1024 into 0,“+”into“-”.

Complete Program:

|

“on start”: command block runs |

|---|---|

Click“JavaScript”, you will see the corresponding JavaScript code:

Then click drop-down triangle button and select“Python”to see the Python language code:

Test Results:

Hook up via connection diagram, upload the code and plug in power. The external LED lights up gradually then gets dark, alternately, which looks like human breath.

Extension Project:

The some LED on 5*5 dot matrix shows the breathing light effect.

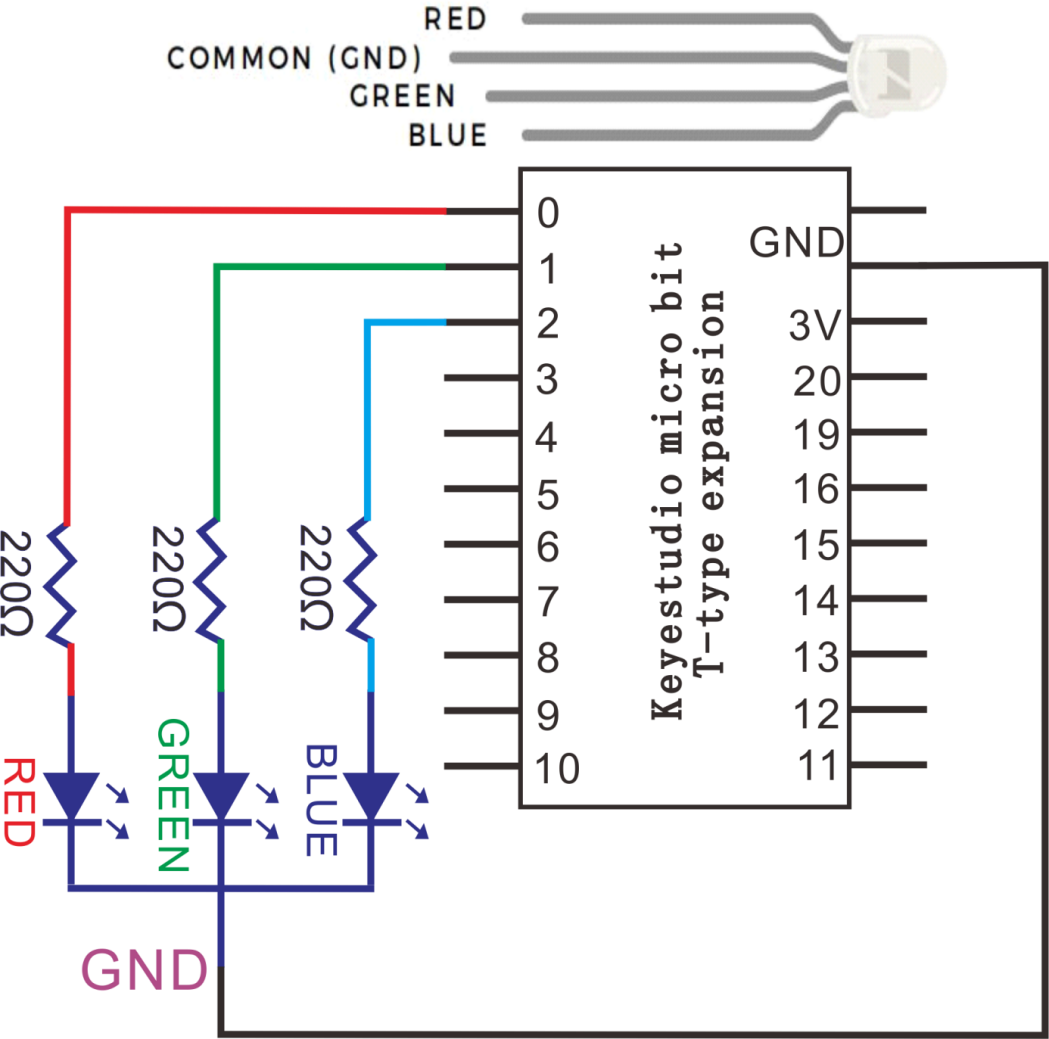

Project 17:RGB

Description:

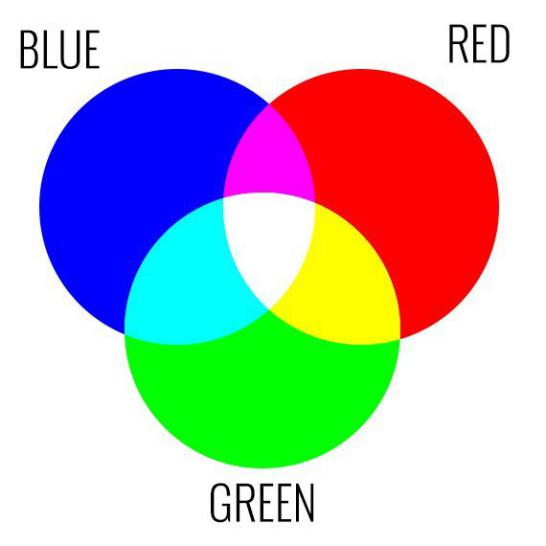

The RGB color mode is a color standard in the industry. It obtains various colors by changing the three color channels of red ®, green (G), and blue (B) and integrating them. RGB denotes the three colors of red, green and blue.

The monitors mostly adopt the RGB color standard, and all the colors on the computer screen are composed of the three colors of red, green and blue mixed in different proportions. A group of red, green and blue is the smallest display unit. Any color on the screen can be recorded and expressed by a set of RGB values.

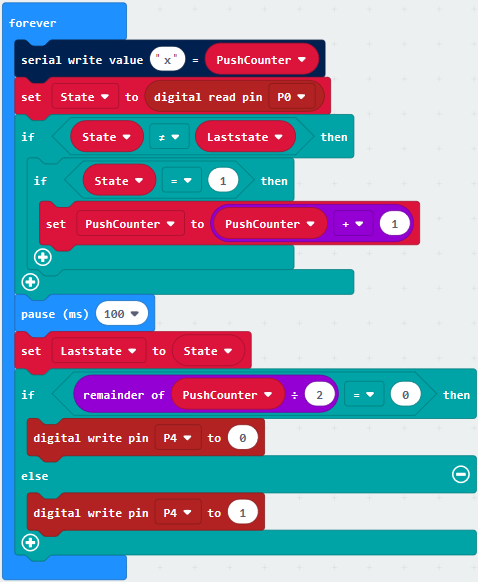

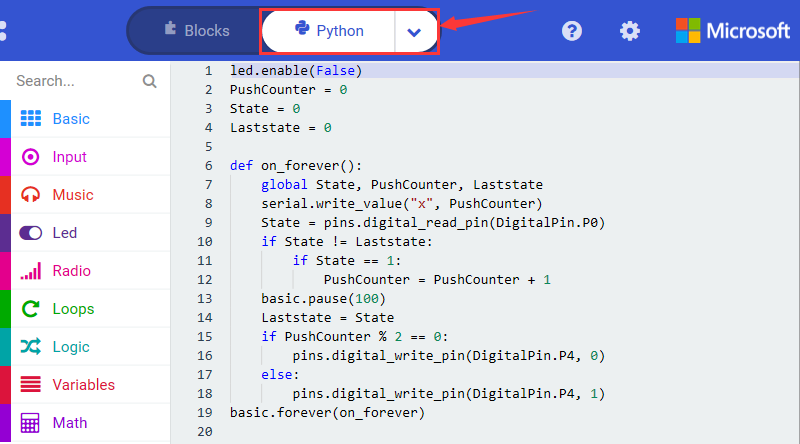

Each of the three color channels of red, green, and blue is divided into 256 levels of brightness. At 0, the “light” is the weakest-it is turned off, and at 255, the “light” is the brightest. When the three-color gray values are the same, the gray tones with different gray values are produced, that is, when the three-color gray is 0, the darkest black is generated; when the three-color gray is 255, it is the brightest white tone .

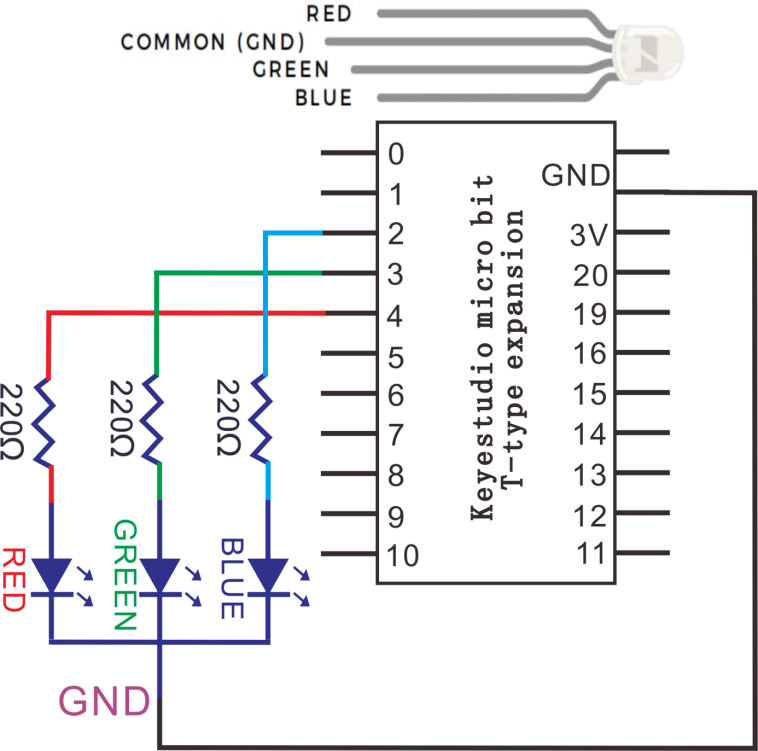

RGB is inclusive of two types. In this project, we adopt a common cathode RGB module and connect it to P4, P3 and P3 of Micro:bit board. The distinct color can be produced and displayed on RGB by changing the input values of P4, P3 and P2.

Component List:

Micro:bit Main Board*1 |

Keyestudio Micro:bit T Type Shield |

RGB*1 |

Micro USB Aable*1 |

|---|---|---|---|

|

|

|

|

220Ω Resistor*3 |

Breadboard*1 |

Breadboard Wire |

|

|

|

|

Schematic Diagram:

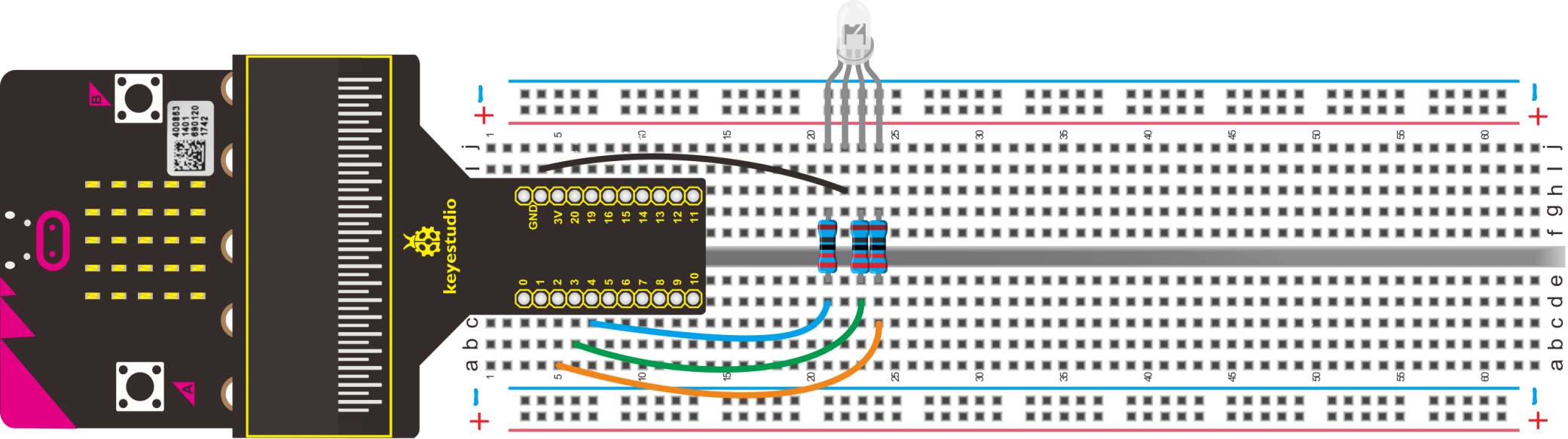

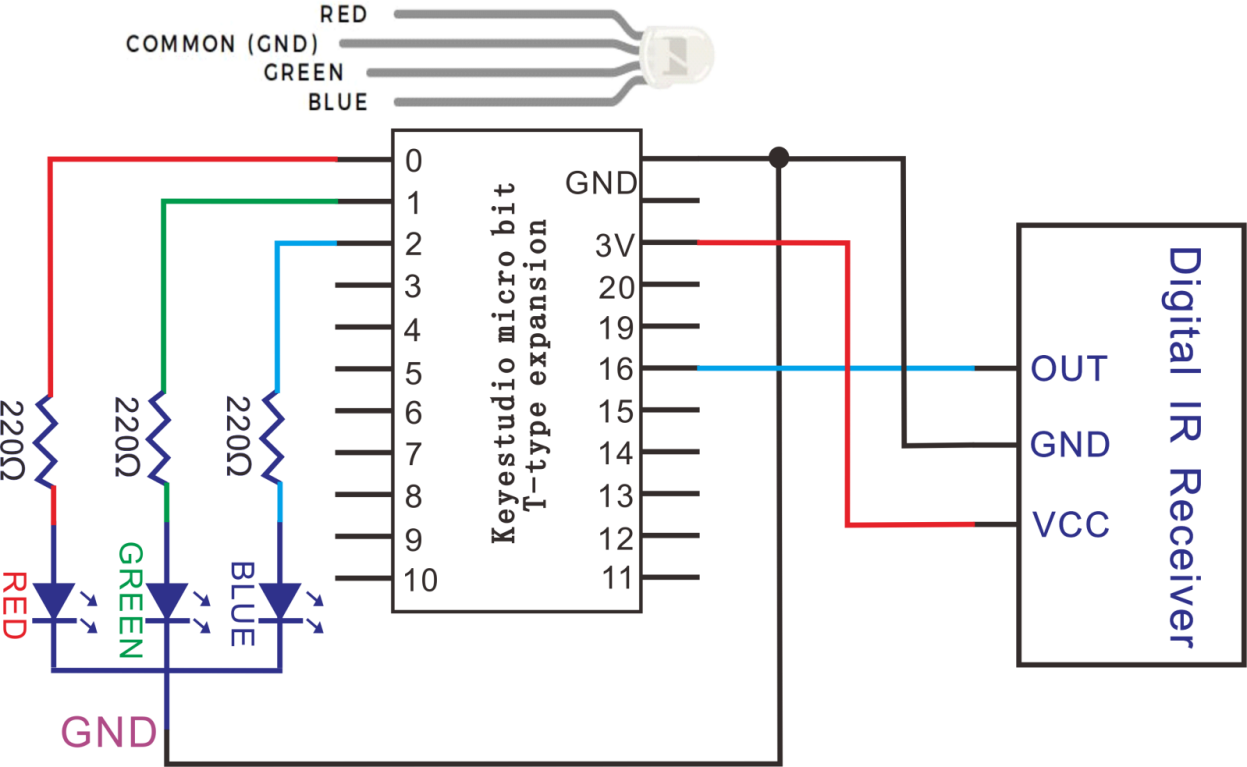

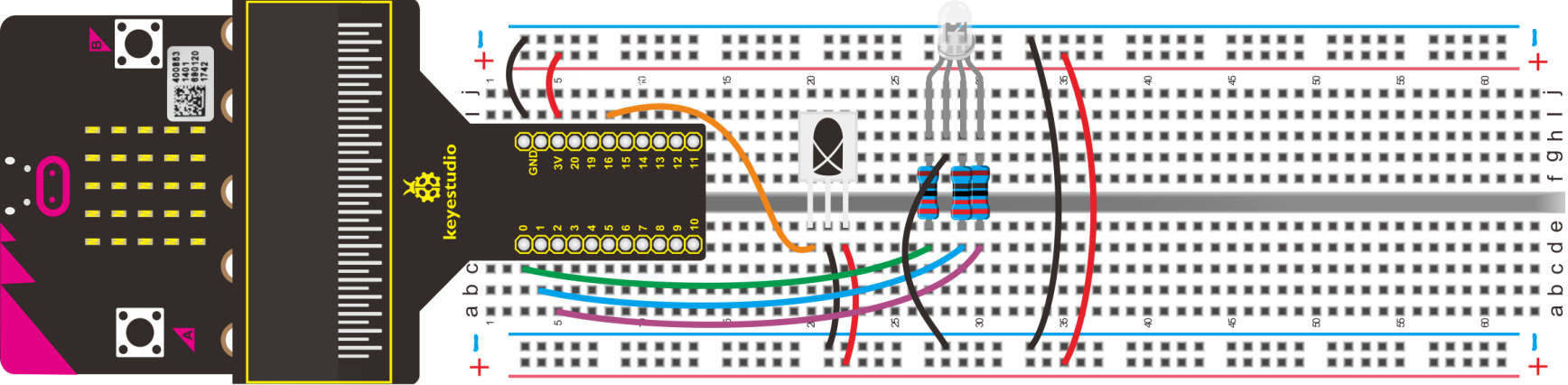

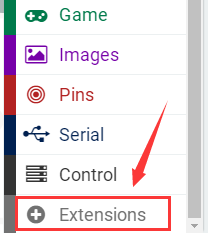

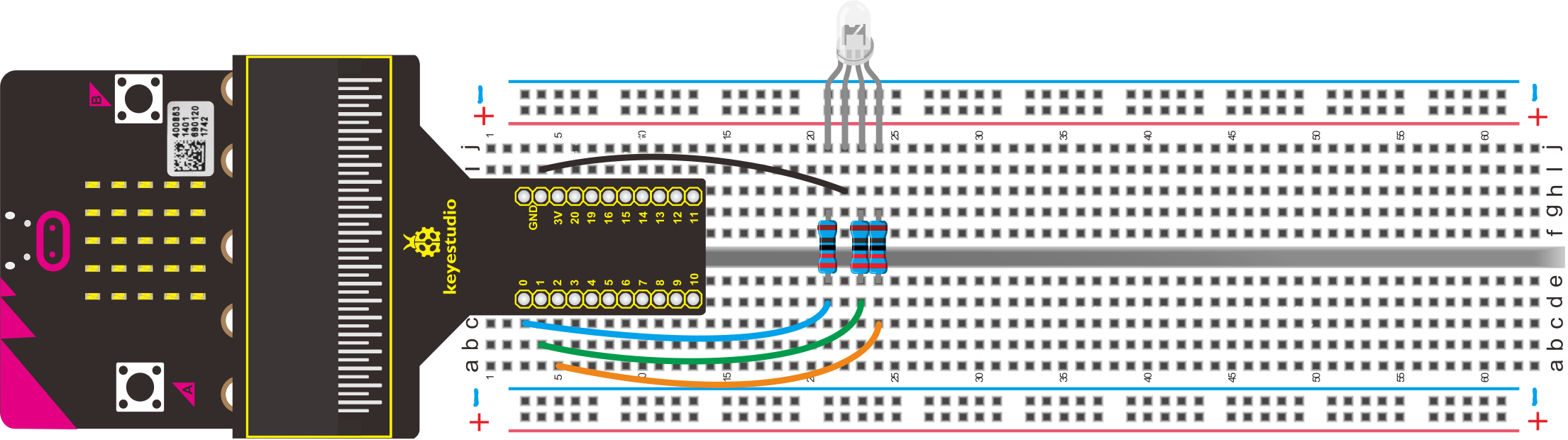

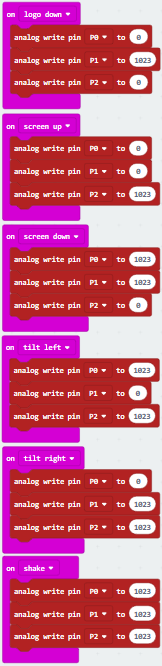

Wiring Graph:

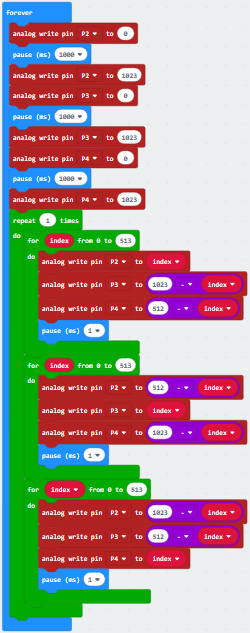

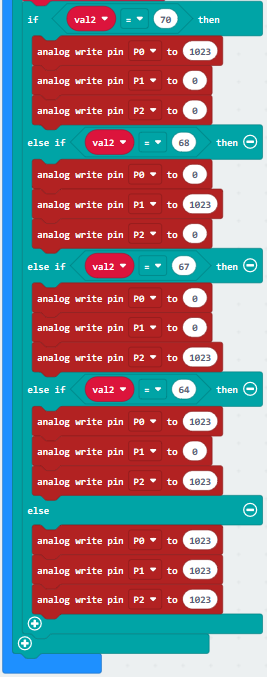

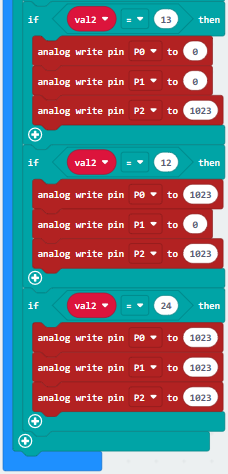

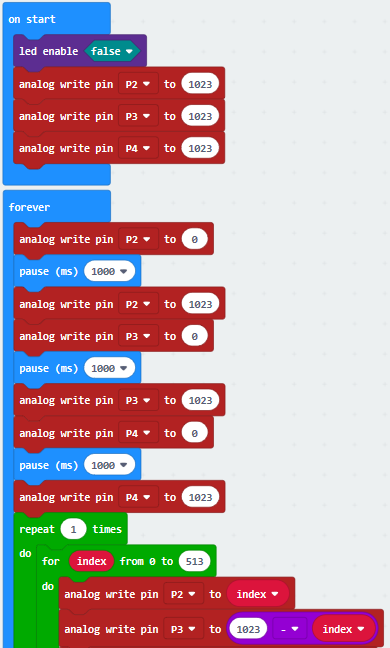

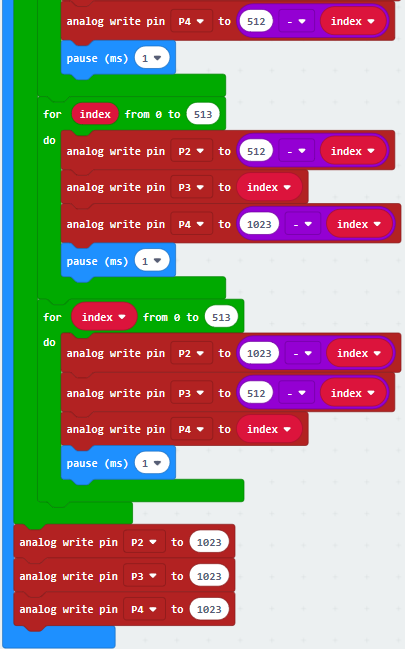

5. Test Code:

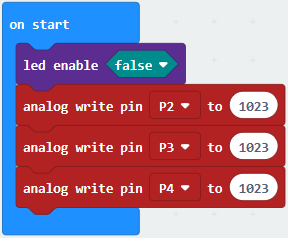

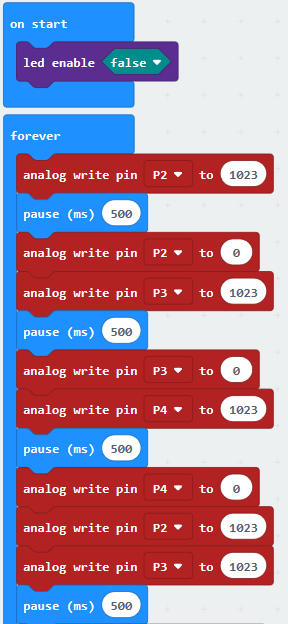

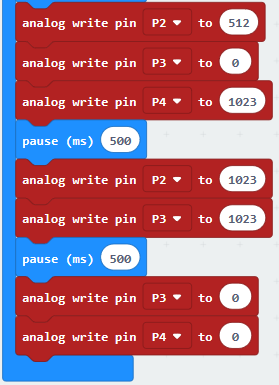

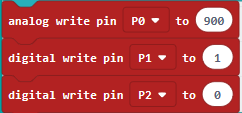

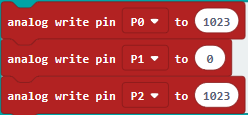

Wiring according to the above diagram. The pins of RGB are linked with P4, P3 and P2. Connect computer to Micro:bit motherboard with USB cable. Then enable Micro: bit online programming tool to design the code:

A. Click“Led”→“more”→“led enable false”

B. Drag “led enable false”into “on start”

*****************************************************************

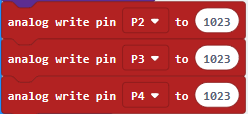

A. Click “Advanced”→“Pins”→“analog write pin P0 to 1023 ”

B. Move it into“on start”block, and copy for 2 times.

C. The pins of RGB are separately connected to P4, P3 and P2. Therefore set to P2, P3 and P4. Then the RGB will show white light.

*****************************************************************

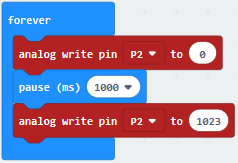

Copy“analog write pin P2 to 1023 ” once and leave it into “forever”, then change 1023 into 0.

*****************************************************************

A. Enter“Basic”→“pause (ms) 100”

B. Put“pause (ms) 100”below the block“analog write pin P2 to 0”block, and set to 1000ms.

*****************************************************************

Duplicate“analog write pin P2 to 1023”again, and place it as follows:

*****************************************************************

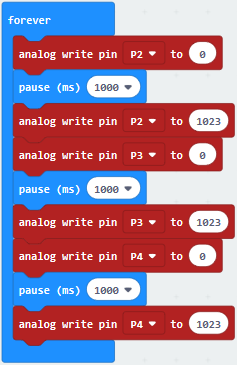

Replicate code string for 2 times, respectively set to P3 and P4. Then combine these code strings as shown below:

code string for 2 times, respectively set to P3 and P4. Then combine these code strings as shown below:

*****************************************************************

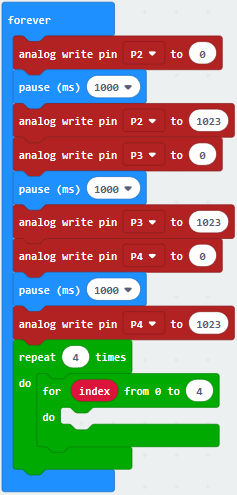

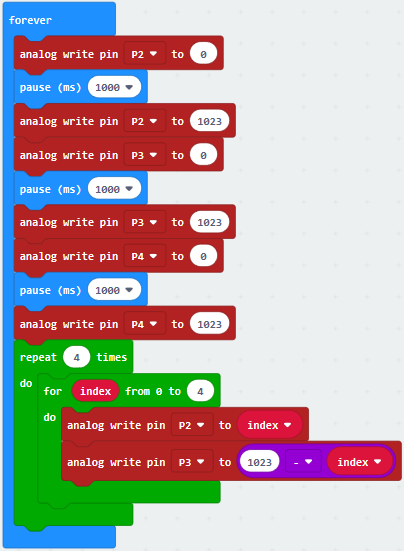

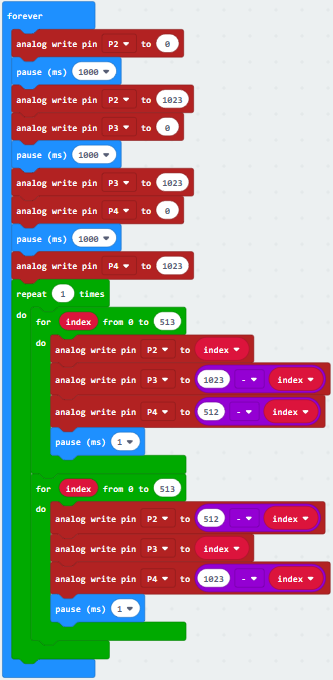

A. Click“Loops”→“repeat 4 times do”

B. Place it into “forever” block.

C. Then drag out the block“for index from 0 to 4…do”from“Loops”, and move it into“repeat 4 times do”block

*****************************************************************

A. Copy“analog write pin P2 to 1023 ”once and leave it into“for index from 0 to 4…do”block.

B. Enter“Variables”→“index”;

C. Put it into“1023” box of“analog write pin P2 to 1023 ”block

*****************************************************************

A. Copy block“analog write pin P2 to index”once;

B. Set to P3 and delete the variable“index”

C. Go to“Math”→ “-”block

D. Leave it into“1023”box, and change left 0 into 1023

E. Move variable“index into right“0”box

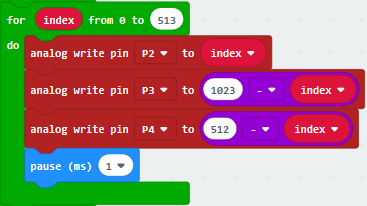

*****************************************************************

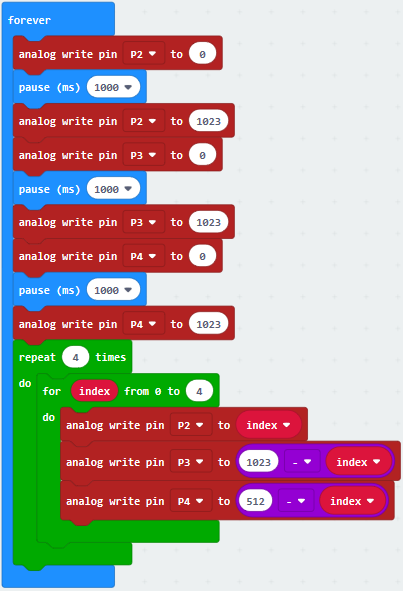

A. Copy“analog write pin P3 to 1023-index”once

B. Click the triangle button to set P4

C. Change 1023 into 512.

*****************************************************************

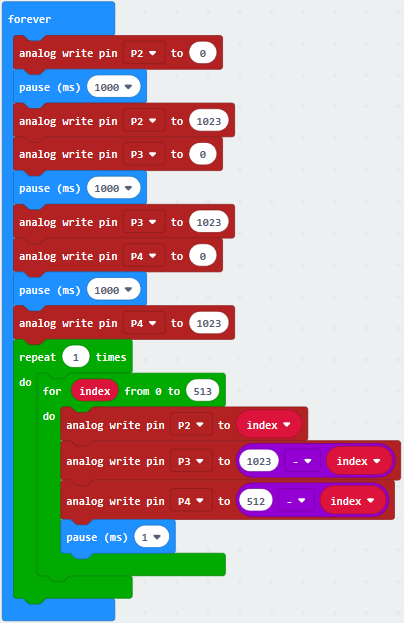

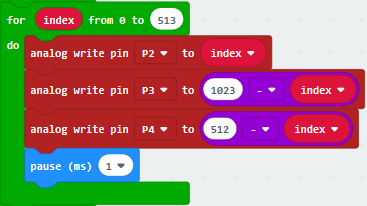

A. Click“Basic”to drag out“pause (ms) 100”, then leave it below “analog write…P4.512…index”block. And set to 1ms.

B. Change“repeat 4 times”into“repeat 1 times”, “for index from 0 to 4”into“for index from 0 to 513”

*****************************************************************

A. Duplicate code string once and leave it into“repeat 1 times do”block

once and leave it into“repeat 1 times do”block

Remove“index”behind P2,“1023-index”behind P3 and “512-index”behind P4.

Then respectively put down“index”into 1023 box behind P3, “512-index”into 1023 box behind P2 and“1023-index”into 1023 box behind P4.

*****************************************************************

A. Replicate code string once and place it into“repeat 1 times do”;

once and place it into“repeat 1 times do”;

Remove“index”behind P2 , “1023-index”behind P3 and “512-index”behind P4.

Respectively drag them into 1023 boxes behind P4, P3 and P2.

*****************************************************************

Copy code string once and move into“forever”block

once and move into“forever”block

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

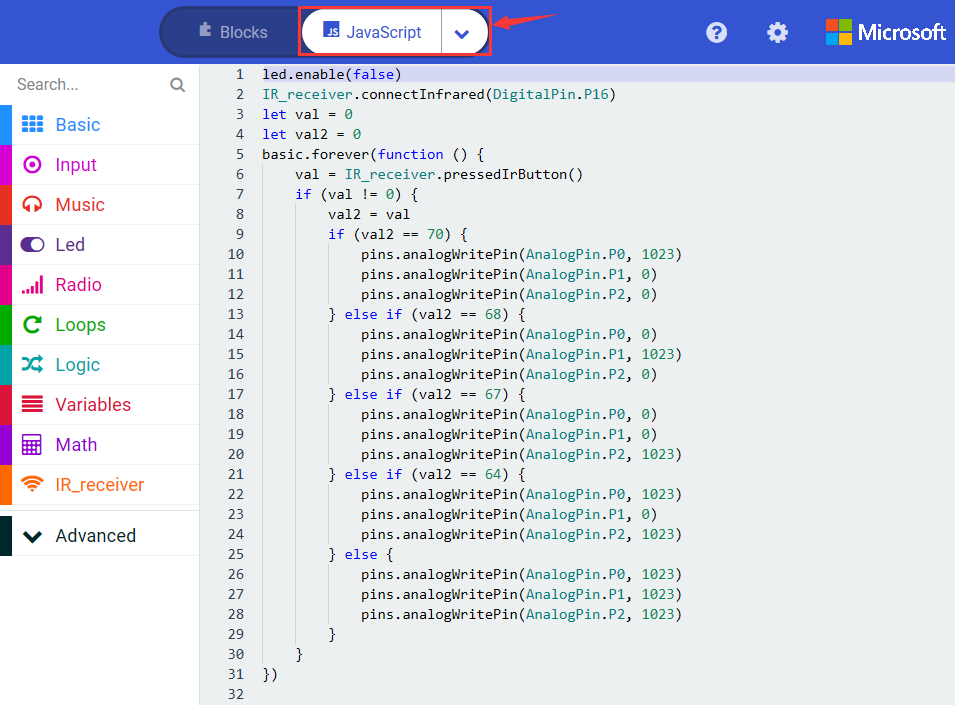

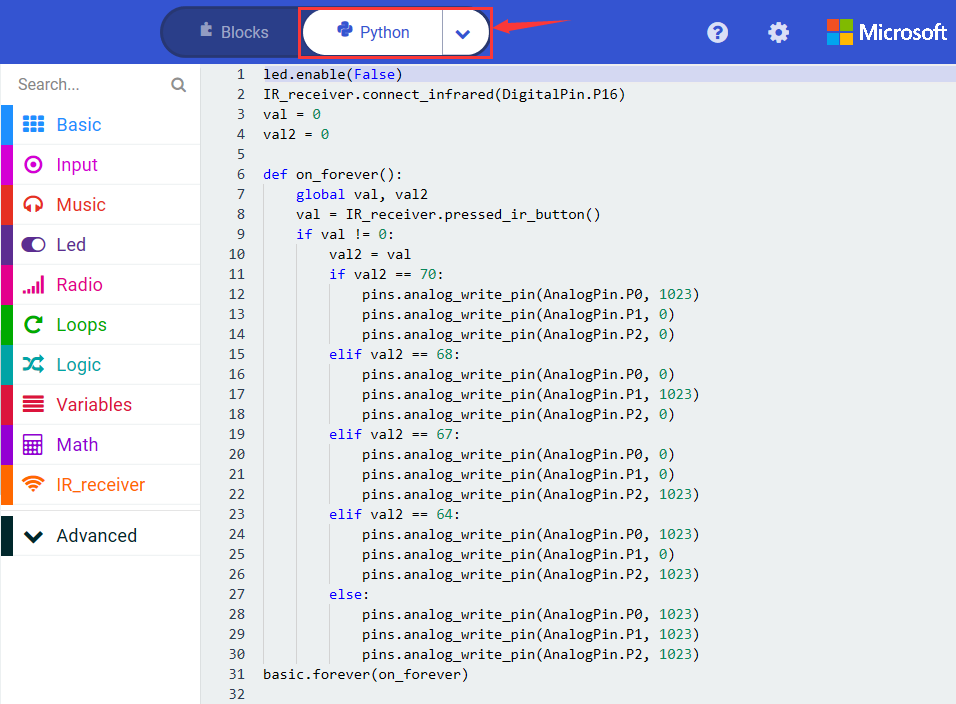

Click“JavaScript”, you will view the corresponding JavaScript code:

Then click the triangle button and select“Python”to see the Python language code:

6. Test Results:

Wire up, upload the code and power on. The RGB begins to show white, blue, green and red color, alternately.

7. Extension Project:

Make RGB display blue, green, red, yellow, purple and white color at the interval of 0.5s, alternately.

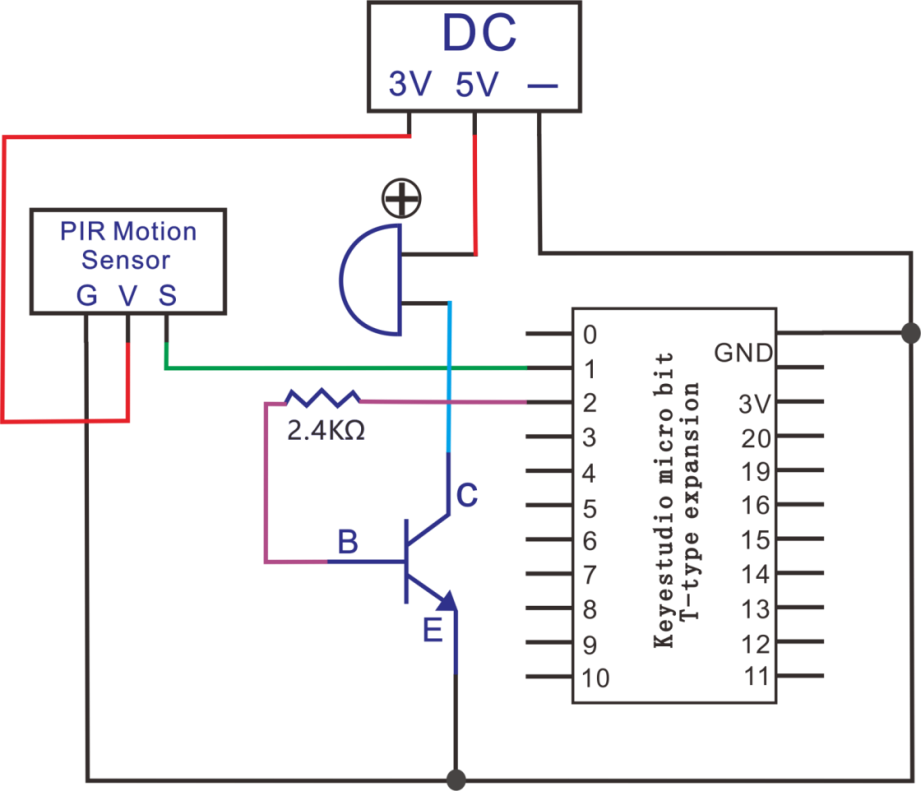

Project 18:Active Buzzer

Description:

We can use Micro:bit to make many interactive works of which the most commonly used is acoustic-optic display. All the previous projects have something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer or a speaker because buzzer is more simpler and easier to use.

The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequencies produce different sounds. We can use Micro:bit to code the melody of a song, which is quite fun and simple.

There are two kinds of buzzer, active buzzer and passive buzzer. In this lesson, we will use Micro:bit to drive an active buzzer. The active buzzer inside has a simple oscillator circuit which can convert constant direct current into a certain frequency pulse signal. Once active buzzer receives a high level, it will produce an audible beep.

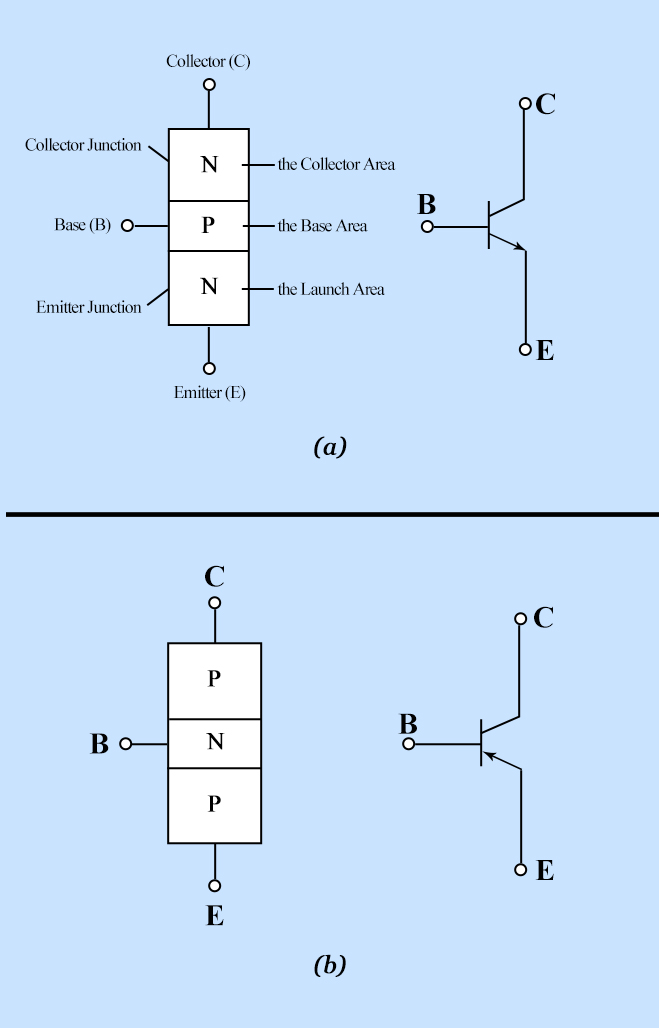

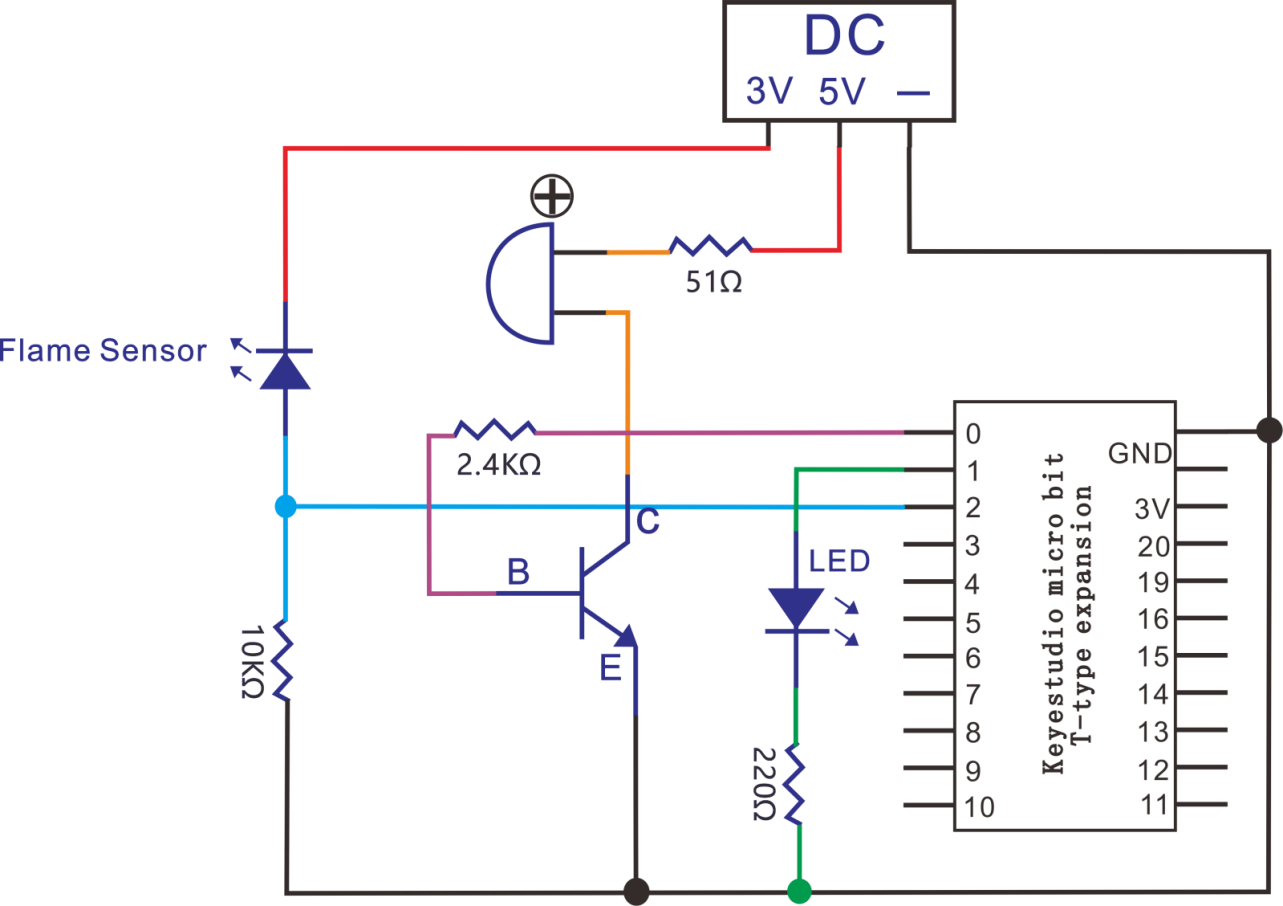

Triode:

Triode, also known as semiconductor triode, bipolar transistor and crystal triode, is a kind of current-controlled semiconductor device. Its function is to amplify weak signals into larger amplitude electrical signals, and also to be used as contactless switches. Crystal triode is one of the basic components of semiconductor. It has the function of current amplification and is the core component of electronic circuit.

The triode is made of two PN junctions which are very close to each other on a semiconductor substrate. The two PN junctions divide the whole semiconductor into three parts, the middle part is the base area, the two sides are the emitter area and collector area, and the arrangement is PNP and NPN.

The NPN triode is composed of 2 N-type and P-type semiconductors, two of which are the launch area and the collect area. And the three pins are called E(Emitter), B (Base) and C (Collector).

The commonly used triodes are divided into PNP and NPN triodes.

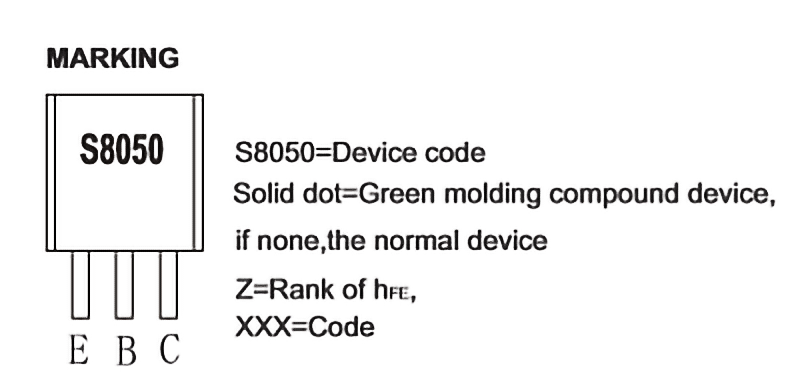

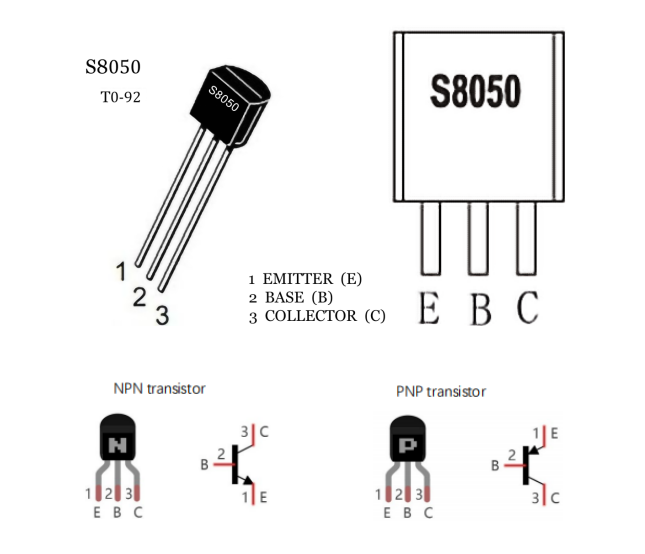

The S8050 transistor is a low-power NPN silicon tube. The collector-base (Vcbo) voltage can be up to 40V, and the collector current is (Ic) 0.5A.

Its three pins are E(Emitter), B (Base) and C (Collector).

>

>

Components List

|

|

|

|

|---|---|---|---|

Micro:bit Main Board*1 |

Keyestudio Micro:bit T Type Shield*1 |

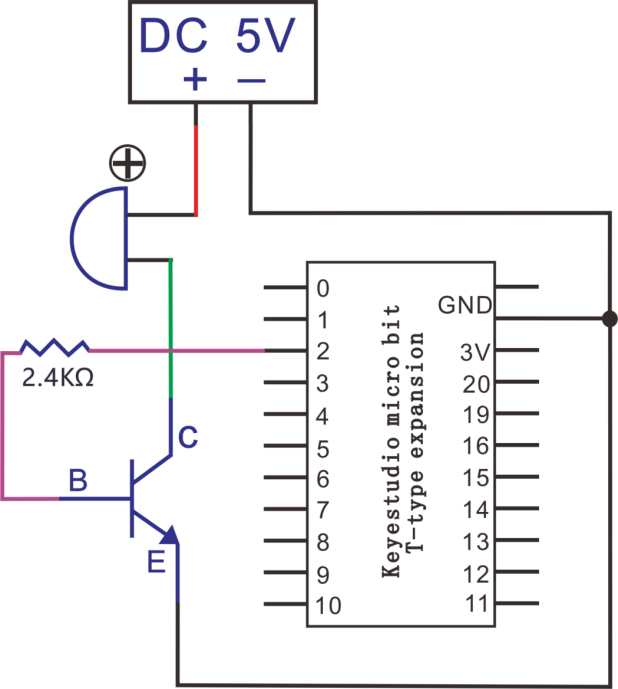

Active Buzzer*1 |

2.4KΩ Resistor*1 |

|

|

|

|

S8050 Triode*1 |

Breadboard*1 |

Breadboard Wire |

Micro USB Cable*1 |

|

|

|

|

Keyestudio Breadboard Power Module*1 |

AA Battery Holder*6 |

5 AA Battery*6 |

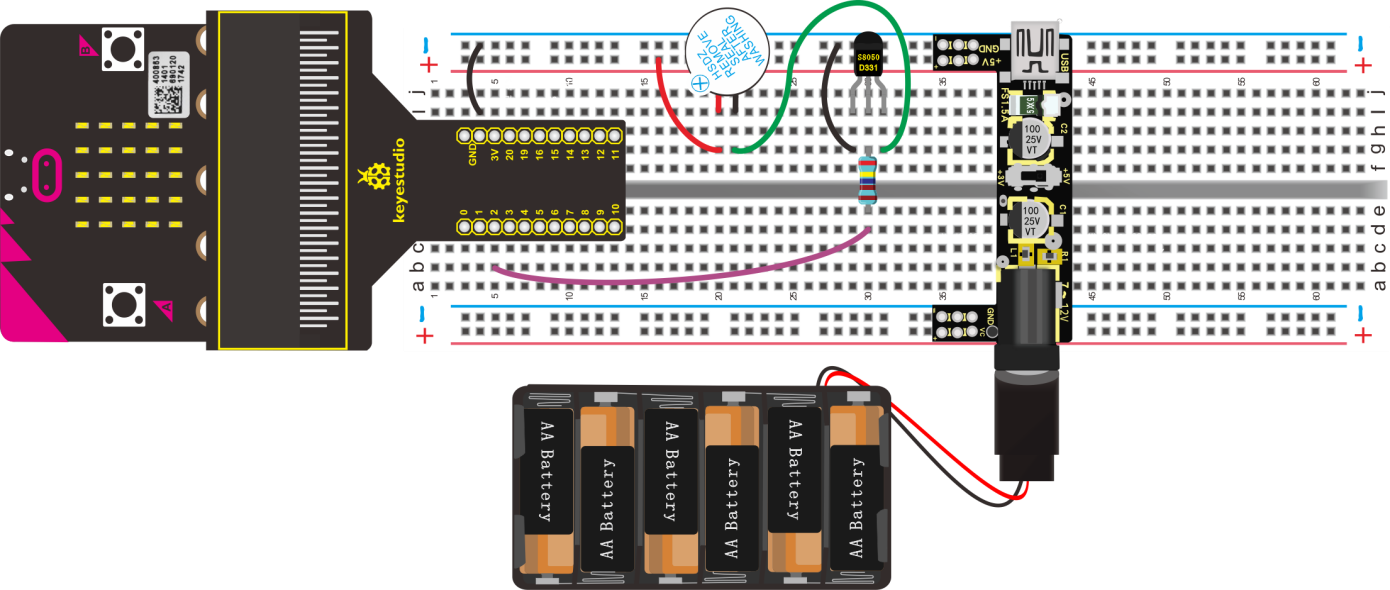

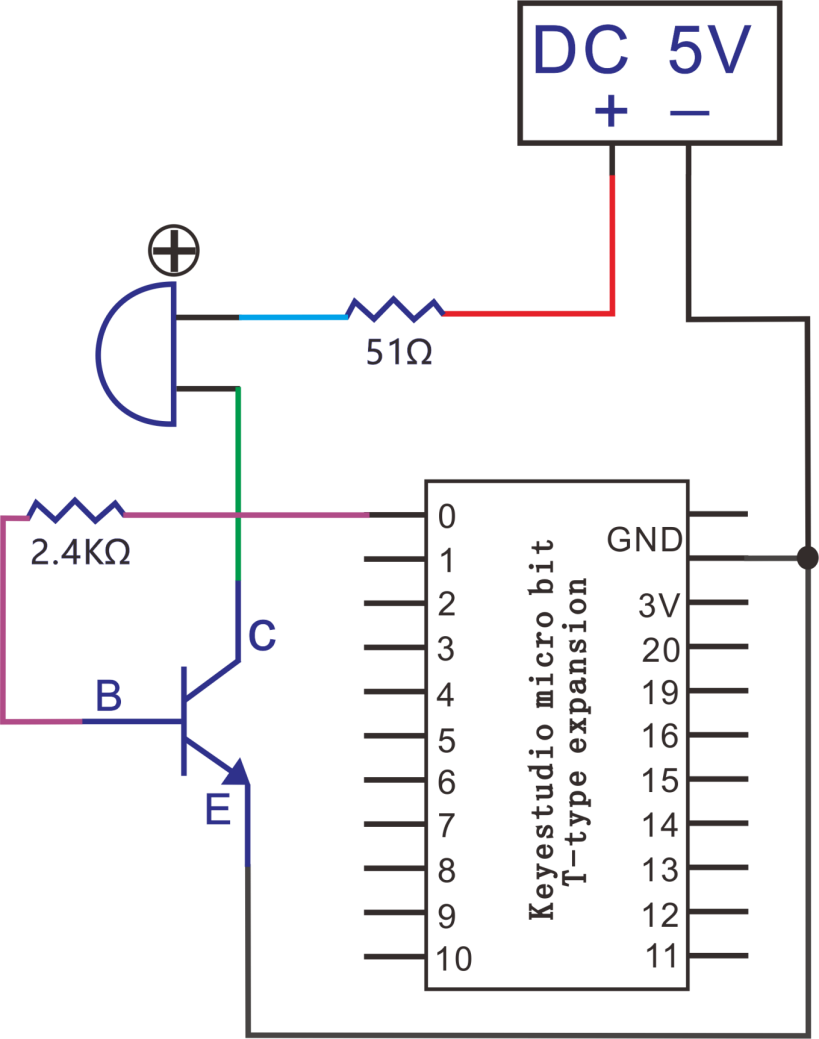

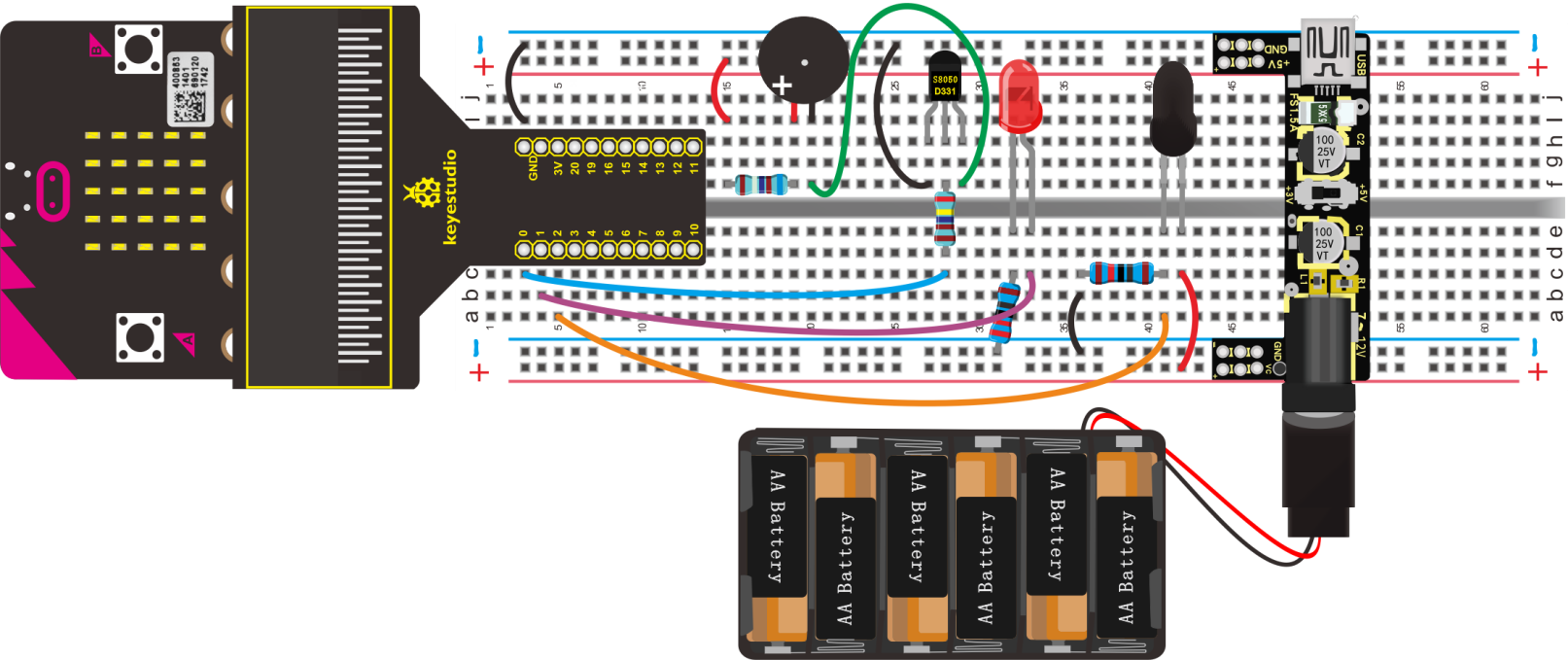

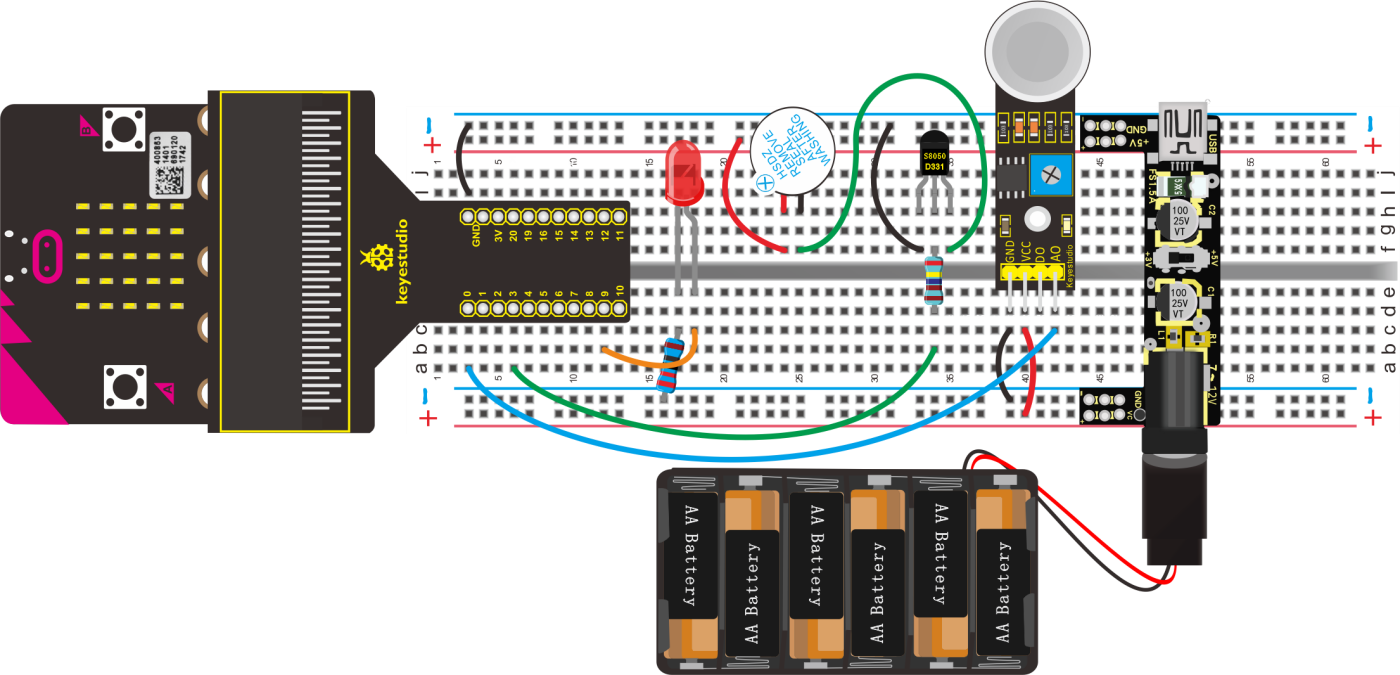

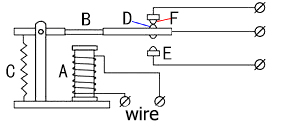

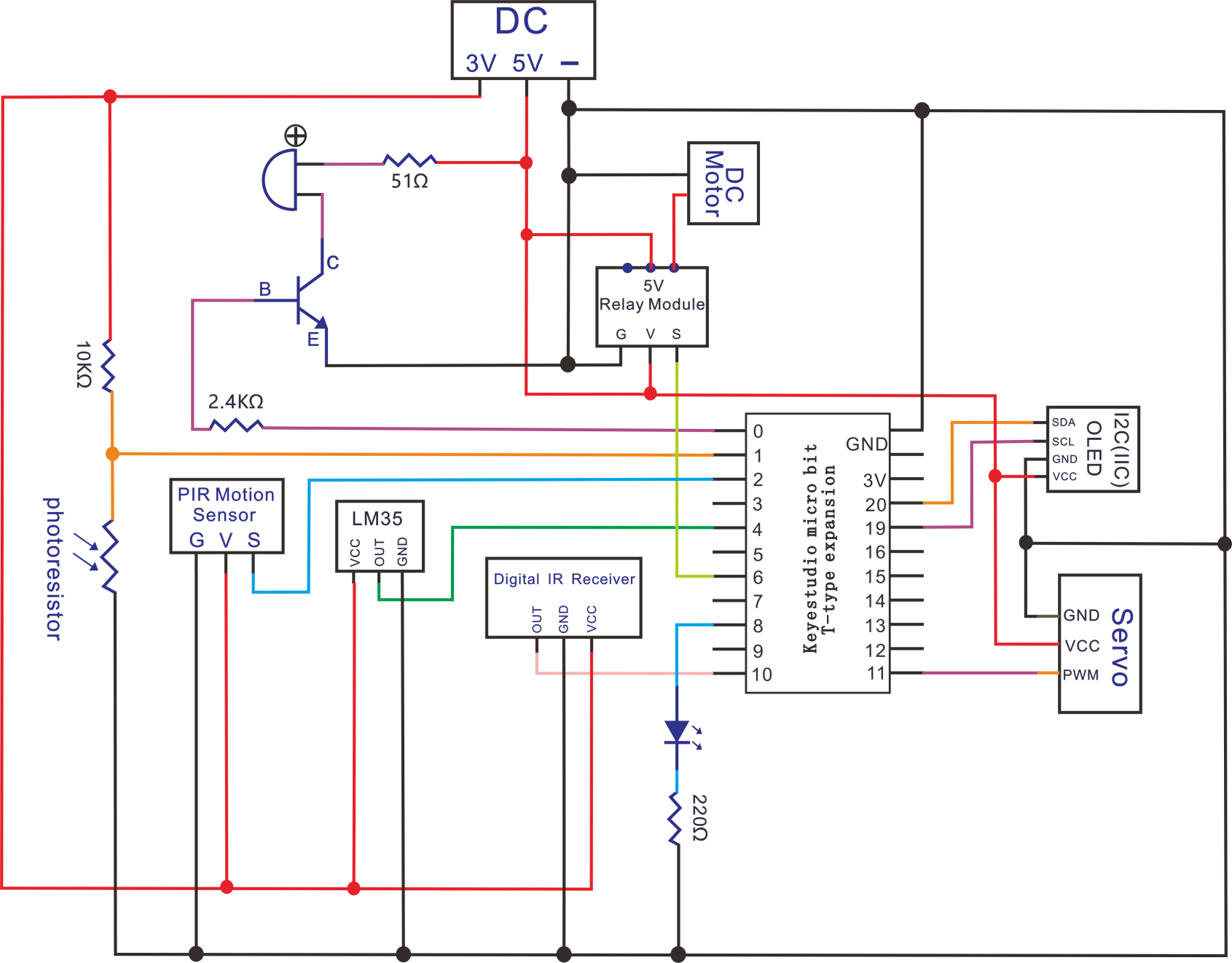

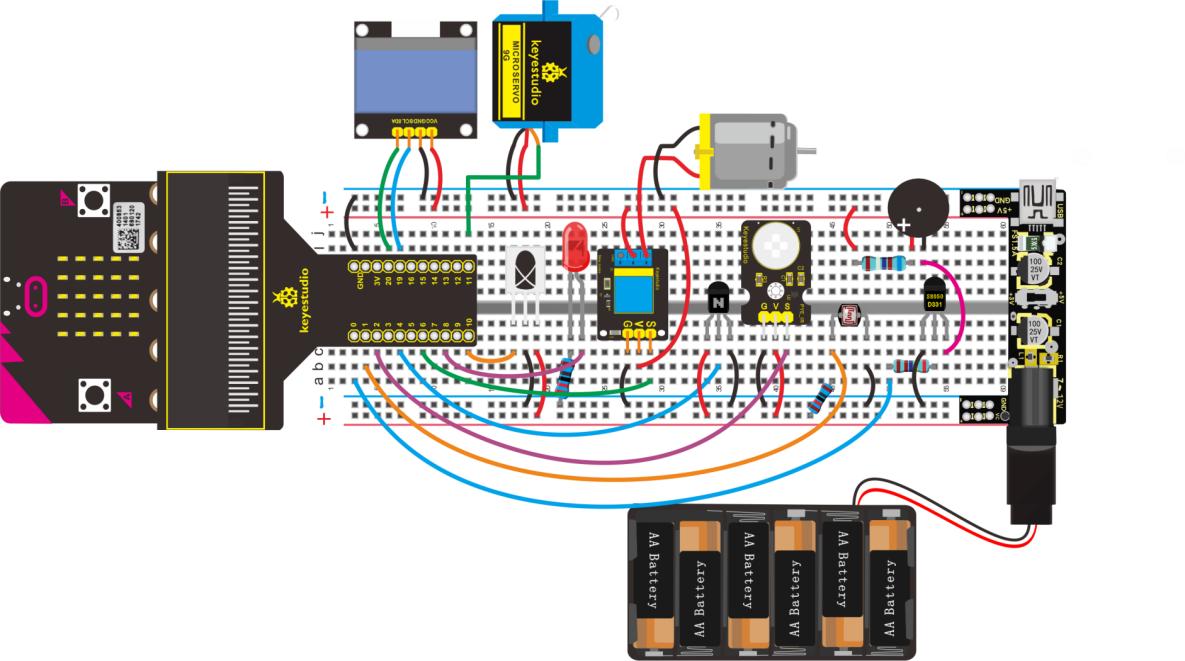

Schematic Diagram:

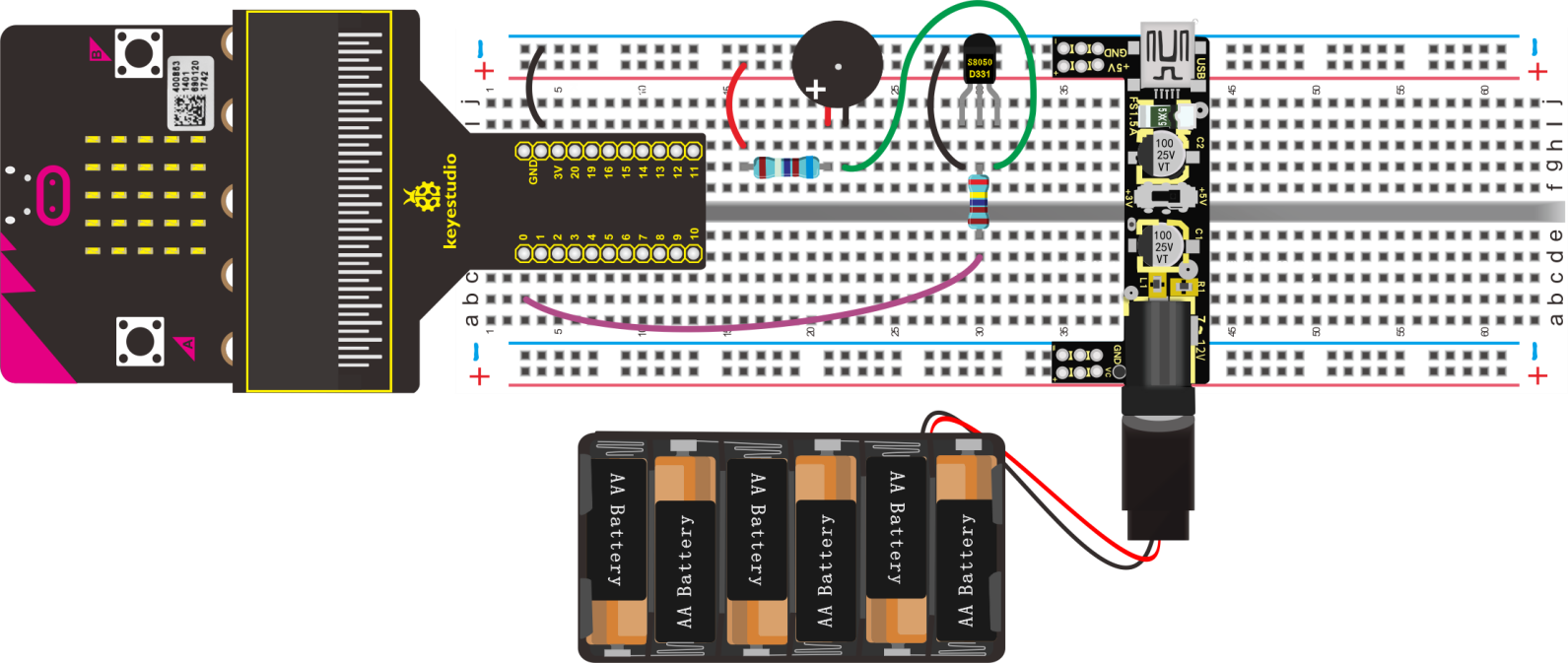

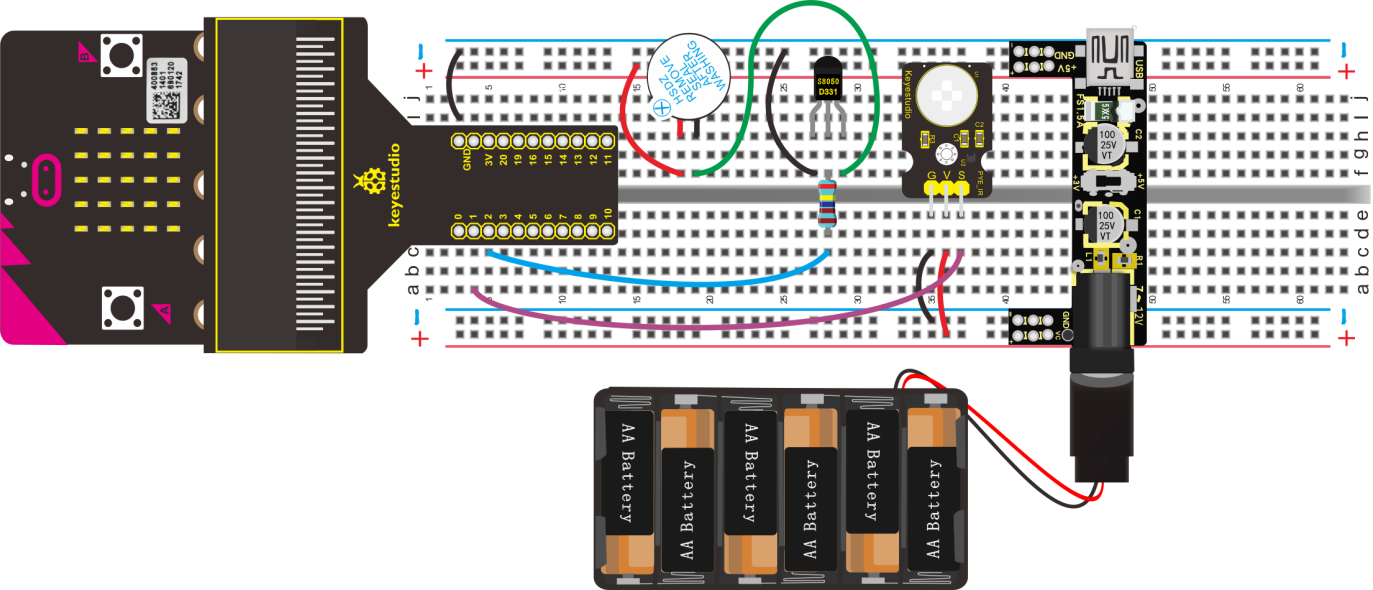

Wiring Graph:

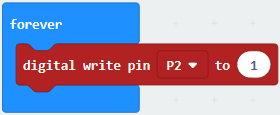

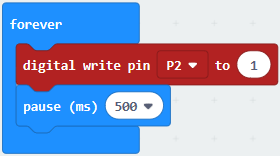

Test Code:

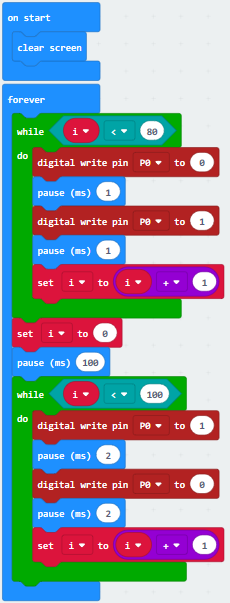

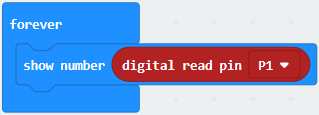

Wiring through the above graph, active buzzer is linked with P2. Link computer with micro:bit board. Then enable the online programming tool to design the code.

(1) 1. Click “Led”→”more”→“led enable false”

Combine it with “on start”.

*****************************************************************

(2) A. Go to“Advanced”→“Pins”→“digital write pin P0 to 0 ”;

B. Leave it into“forever” , and active buzzer is connected to P2, so set to P2, change o into 1.

*****************************************************************

(3) Click“Basic”to move“pause (ms) 100”block below “digital write…P2 to 1”block, set to 500ms.

*****************************************************************

(4) Duplicate the code string  once and move it below “pause(ms)500”block. Then change 1 into 0.

once and move it below “pause(ms)500”block. Then change 1 into 0.

*****************************************************************

Complete Program:

|

“on start”: command block runs once to start program. |

|---|---|

Click“JavaScript”, you will view the corresponding JavaScript code:

Then click drop-down triangle button and select“Python”to see the Python language code:

5. Test Results:

Upload program and plug in power. Active buzzer emits sound for 0.5s, and stops for 0.5s.

6. Extension Project:

Shift the IO port of active buzzer, it makes sound for 0.2s alternately.

Project 19:Passive Buzzer

Description:

We can use Micro:bit board to make many interactive works of which the most commonly used is acoustic-optic display. The previous lessons are related to LED. However, we will elaborate the Sound in this lesson.

Buzzer is inclusive of active buzzer and passive buzzer.

The passive buzzer doesn’t carry with vibrator inside, so it need external sine or square wave to drive. It can produce slight sound when connecting directly to power supply. It features controlling sound frequency and producing the sound of “do re mi fa so la si”.

A diode should be connected in reverse when driving by the square wave signal source, which will hinder the high-voltage generated to damage other components or service life when the power breaks down.

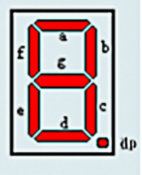

Frequency is made of a series of pitch names in English letters and Numbers. You can choose different frequencies, that is, tone. The frequency of sound is called pitch.

It involves music knowledge. In music lesson, our teacher taught“1(Do), 2(Re), 3(Mi), 4(Fa) , 5(Sol), 6(La), 7(Si)”

1(Do) |

2(Re) |

3(Mi) |

4(Fa) |

5(Sol) |

6(La) |

7(Si) |

|---|---|---|---|---|---|---|

C |

D |

E |

F |

G |

A |

B |

The number depends on high or low tone. The larger the number, the higher the tone. When the number is same, the frequency (tone) is getting higher and higher from C to _B.

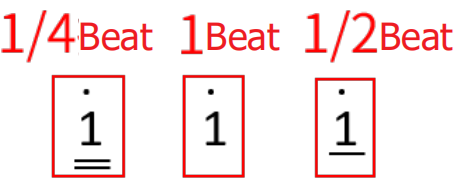

Beats are the time delay for each note. The larger the number, the longer the delay time. A note without a line in the spectrum is a beat, with a delay of 1000 milliseconds. while a beat with an underline is 1/2 of a beat without a line, and a beat with two underlines is 1/4 of a beat without a line.

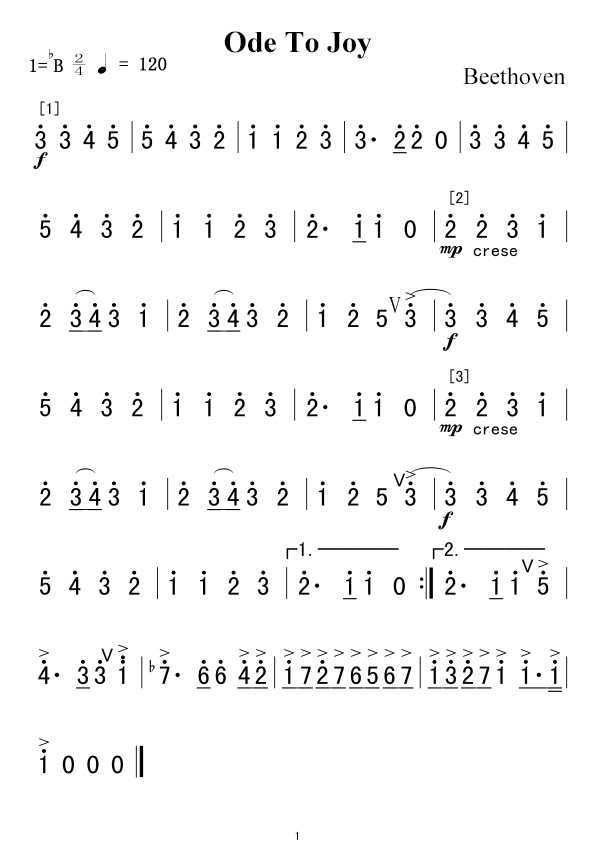

Here is the notation of Ode to Joy.

2. Components List:

|

|

|

|

|---|---|---|---|

Micro:bit motherboard*1 |

keyestudio Micro:bitT Type Shield*1 |

Passive Buzzer*1 |

2.4KΩResistor*1 |

|

|

|

|

S8050Triode*1 |

AA Battery Holder*6 |

Breadboard wire |

Micro USB cable*1 |

|

|

|

|

Breadboard*1 |

Keyestudio Power module for breadboard*1 |

51ΩResistor*1 |

AA Battery*6 |

3. Schematic Diagram:

(Note: On Micro:bit motherboard,Passive Buzzer is only connected to P0)

Wiring Graph:(Note: On Micro: bit mainboard,Passive Buzzer is only connected to P0)

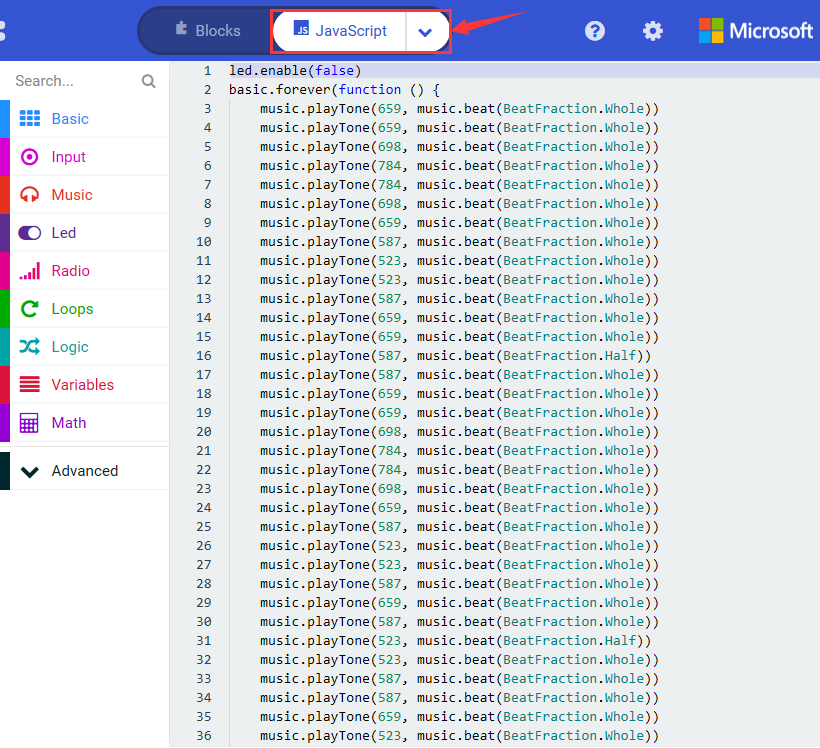

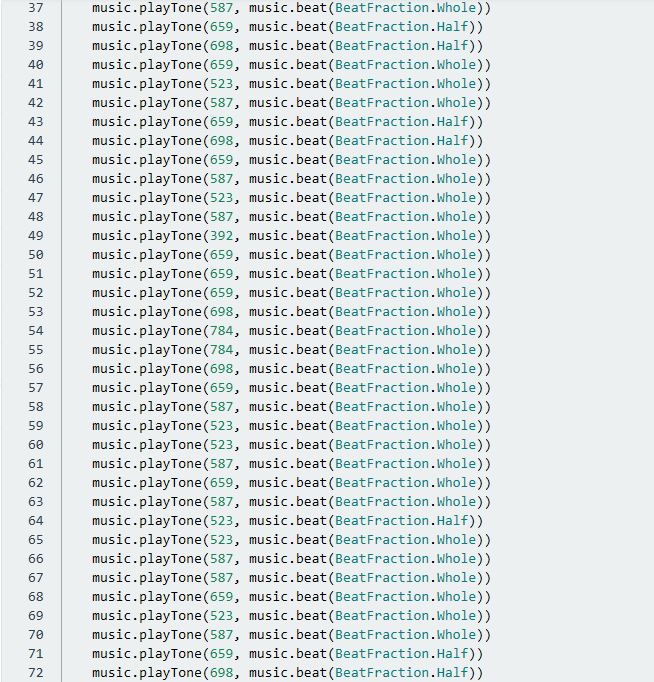

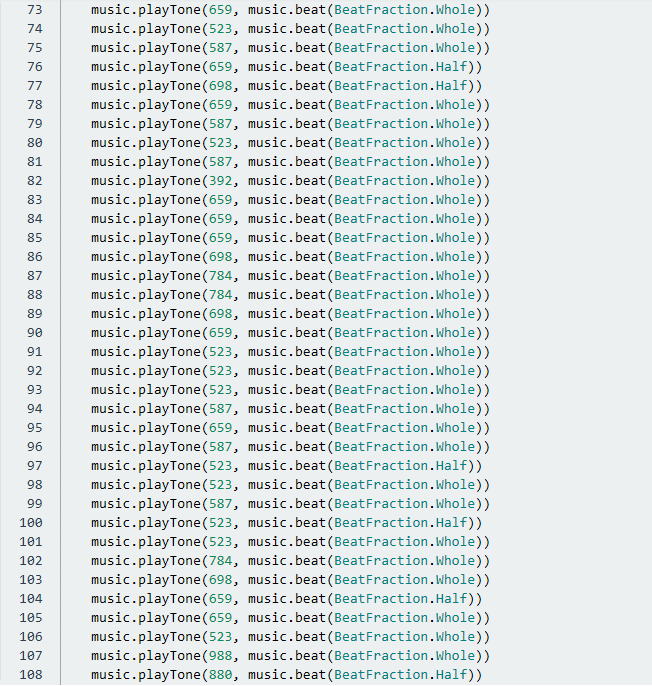

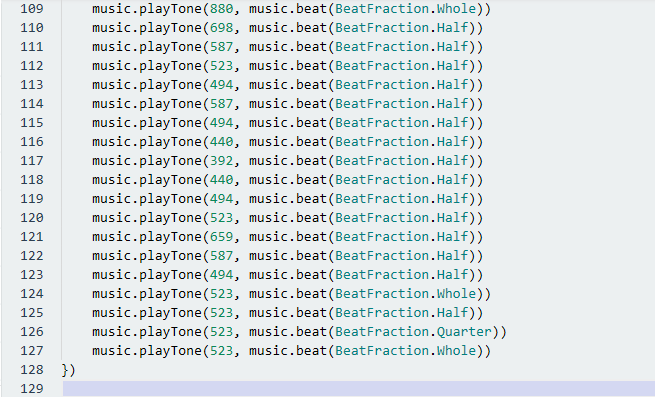

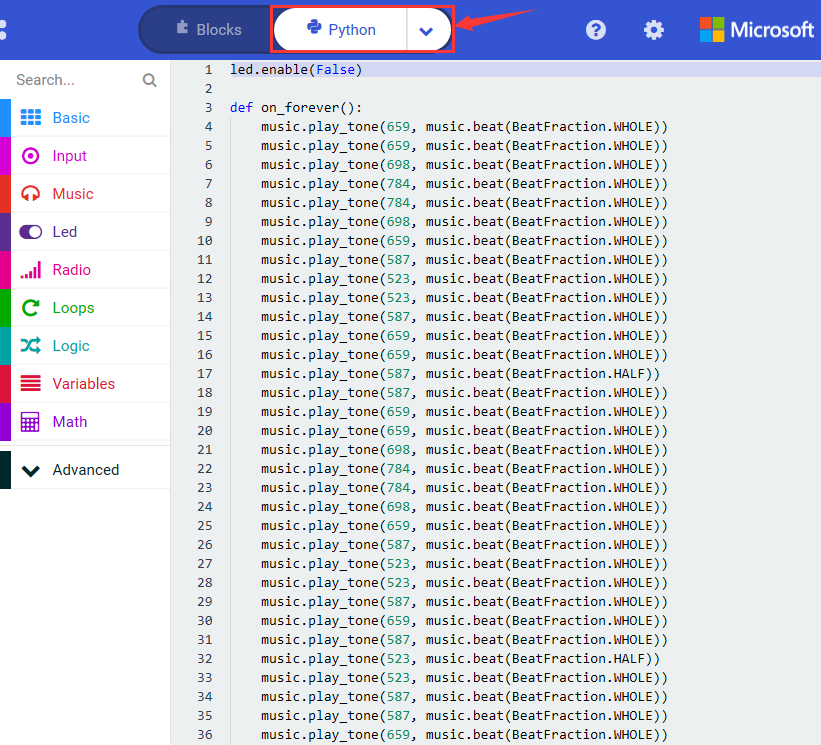

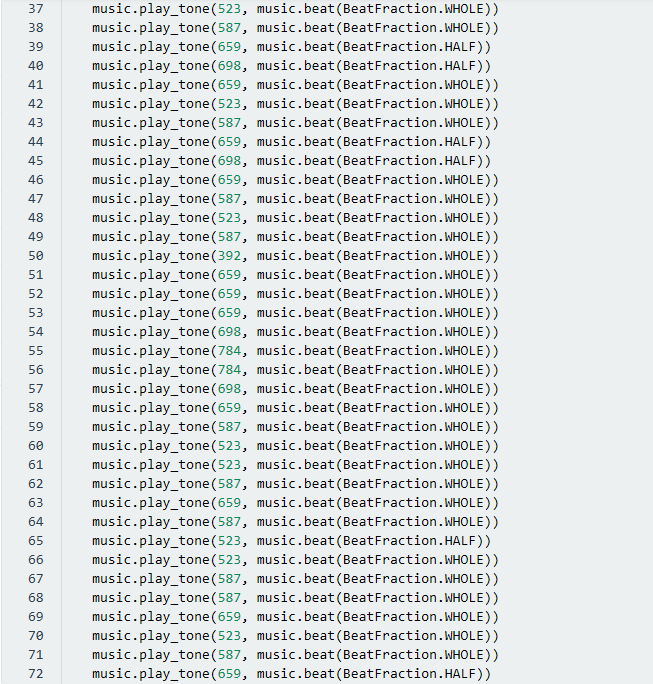

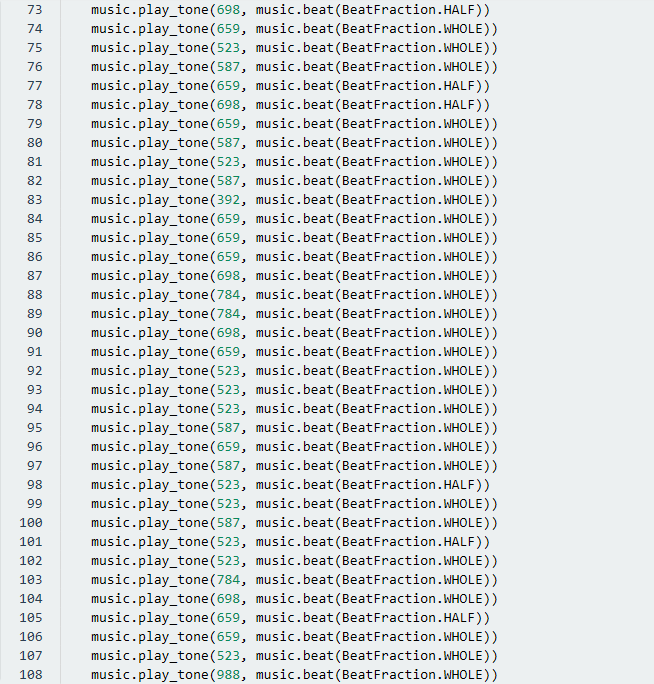

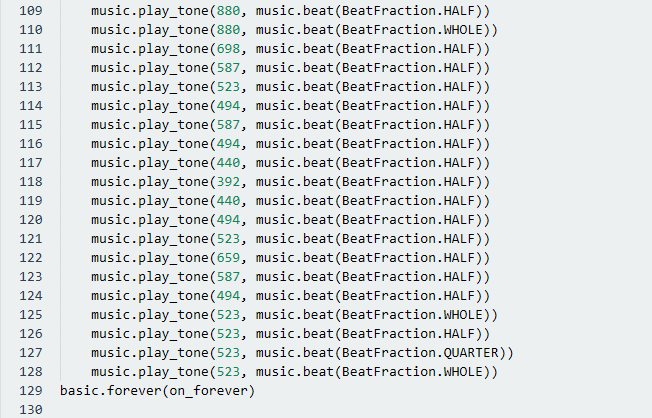

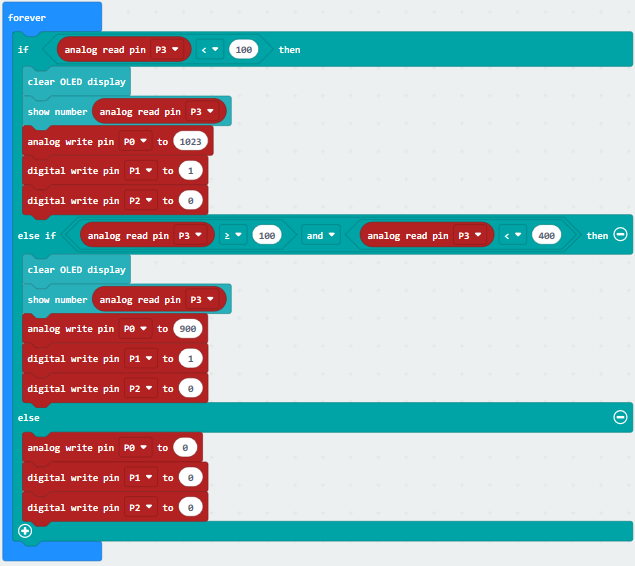

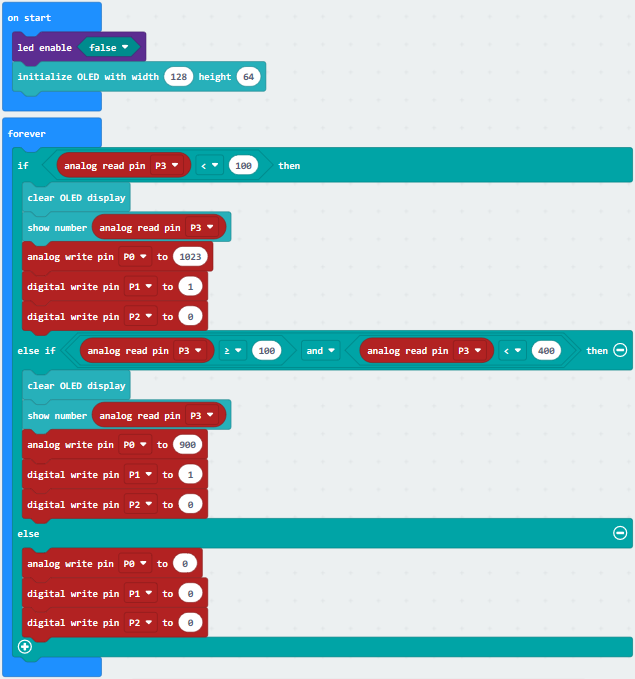

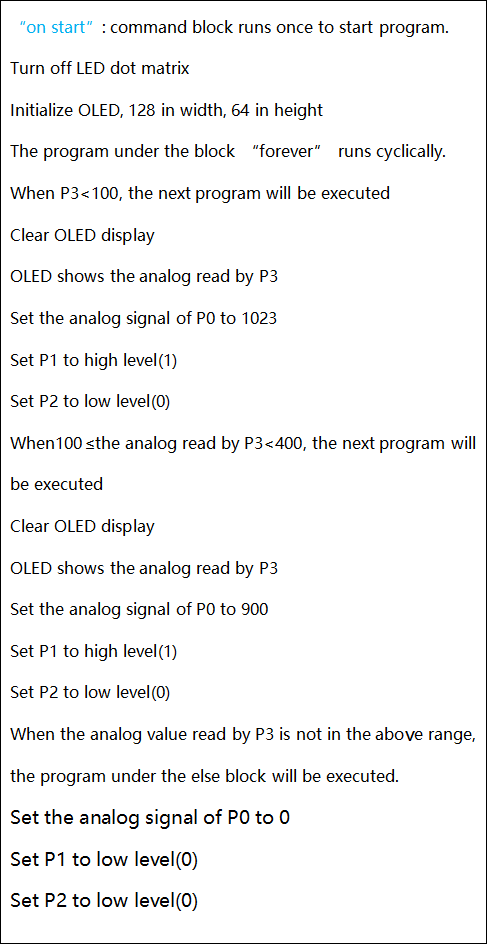

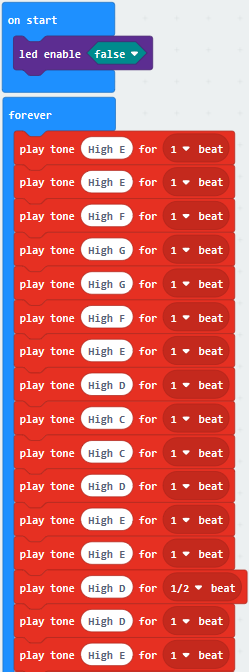

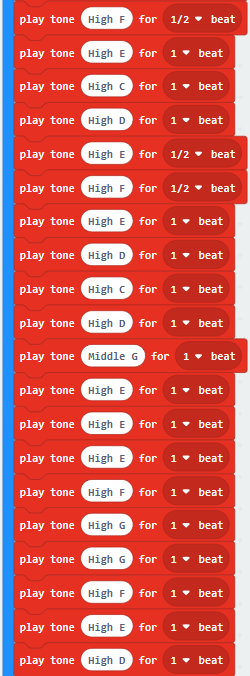

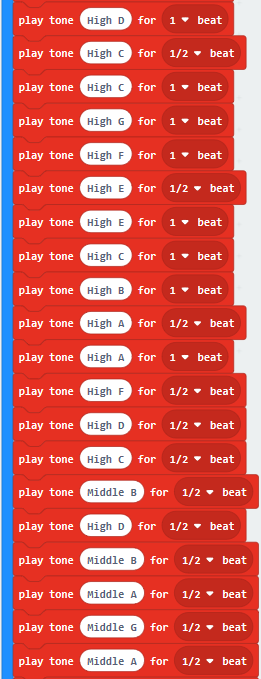

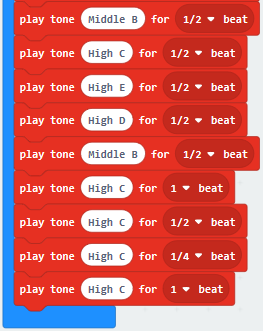

4. Test Code:

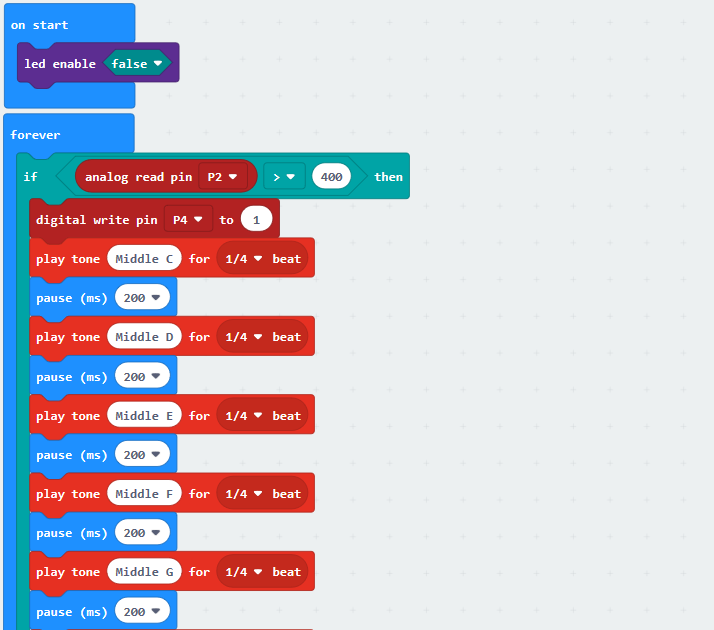

Wiring through the above graph, passive buzzer is linked with P0. Link computer with micro:bit board. Then enable the online programming tool to design the code.

Click “Led”→”more”→“led enable false”, combine it with “on start”.

*****************************************************************

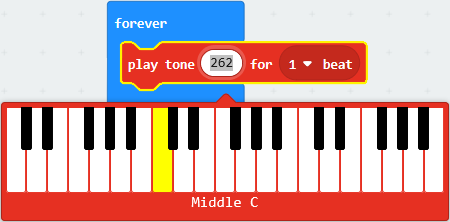

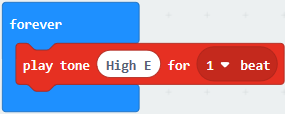

Enter“Music”→“play tone Middle C for 1 beat”, leave it into“forever”block,then tap “Middle C”, then appear code.

code.

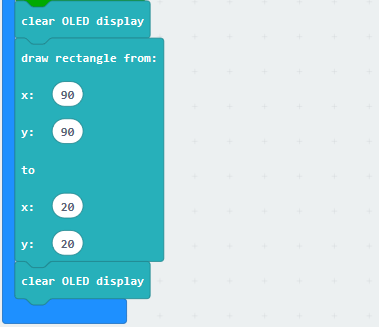

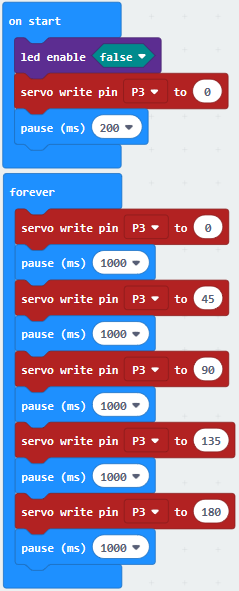

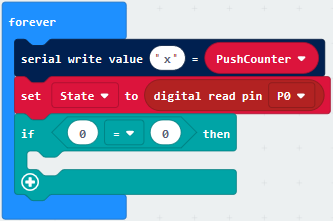

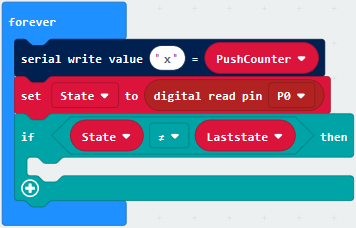

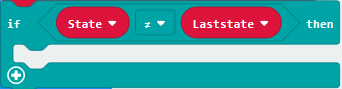

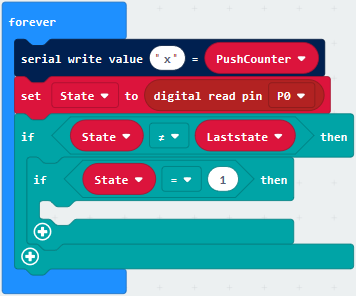

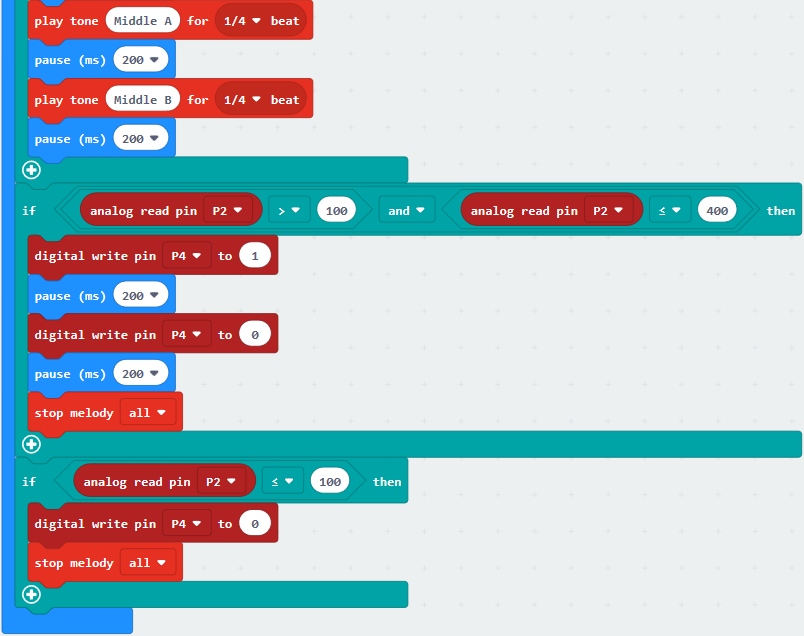

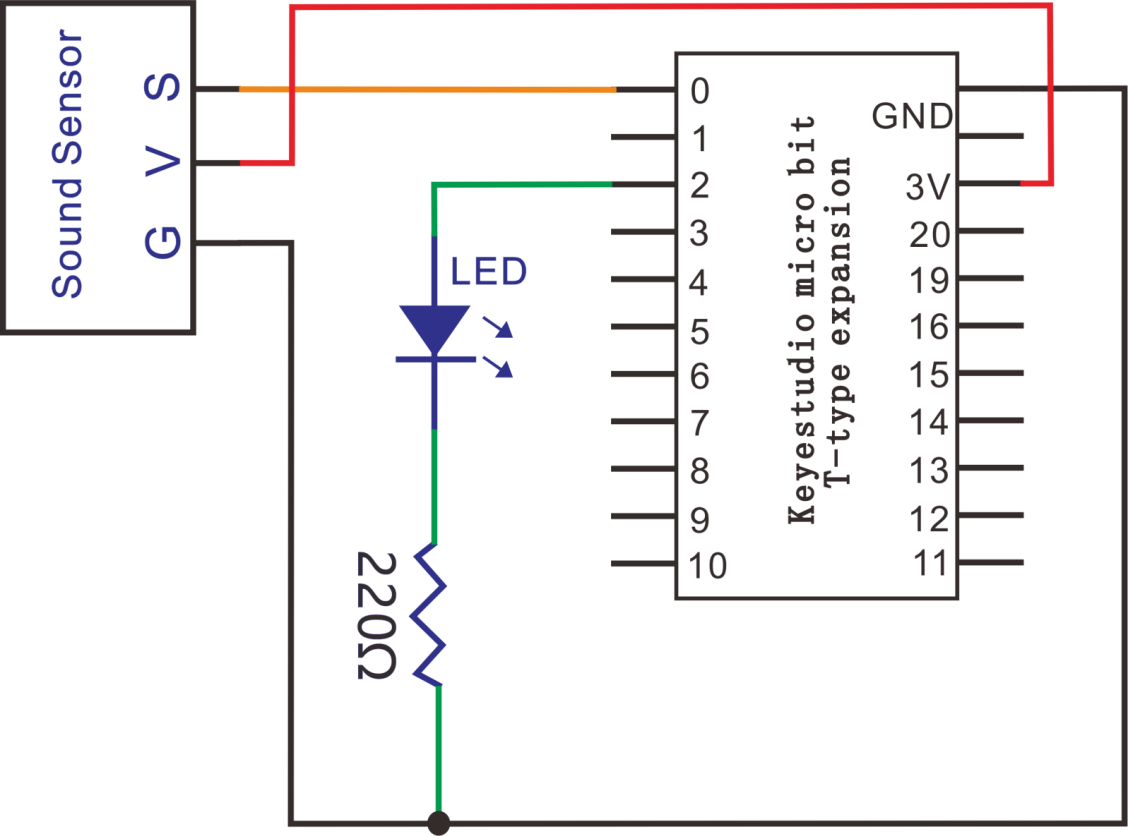

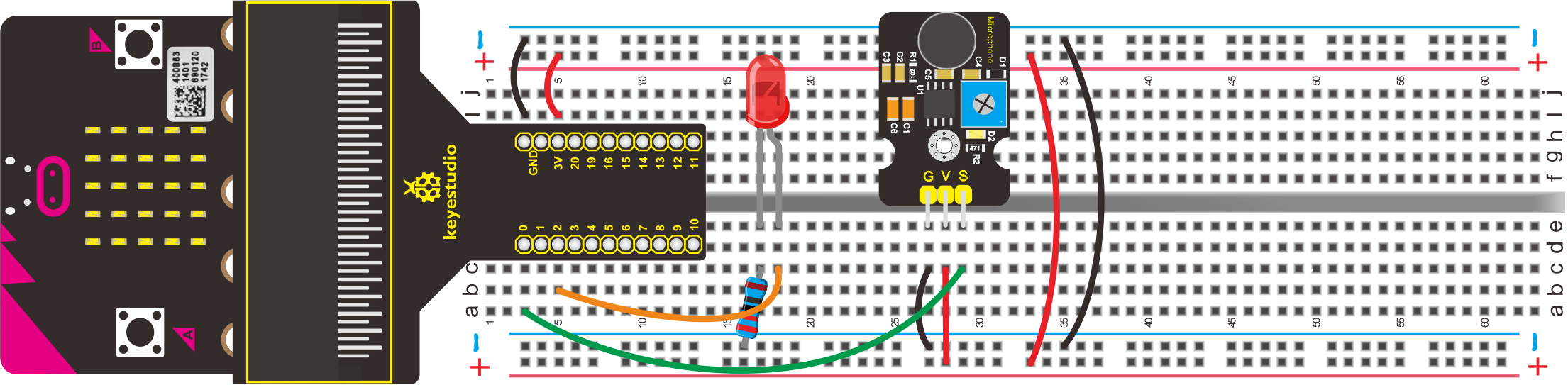

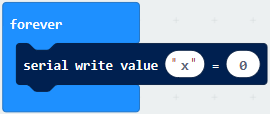

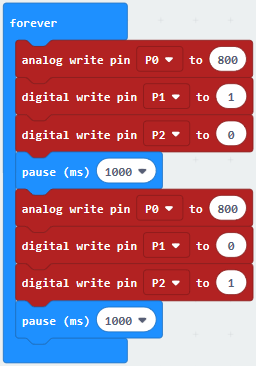

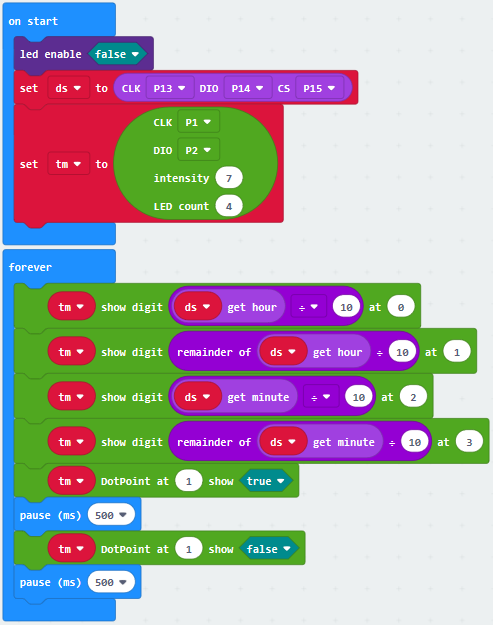

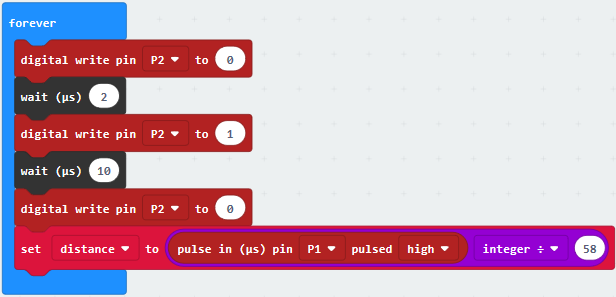

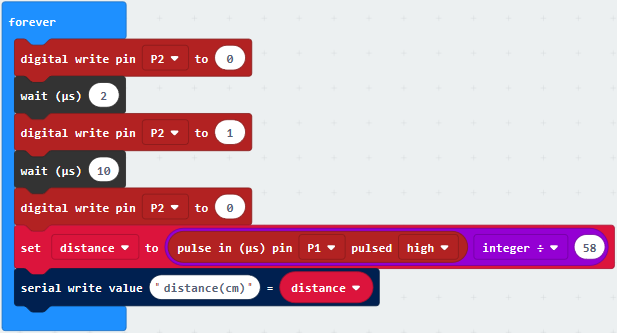

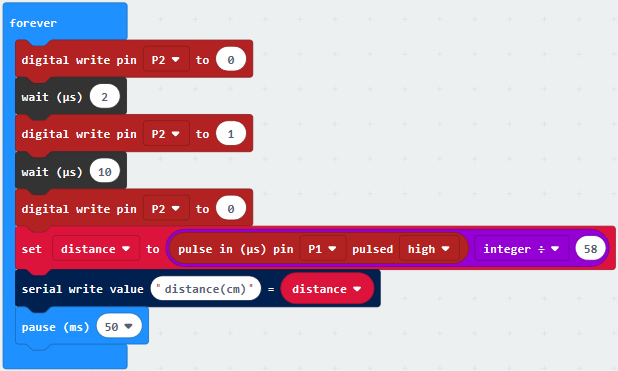

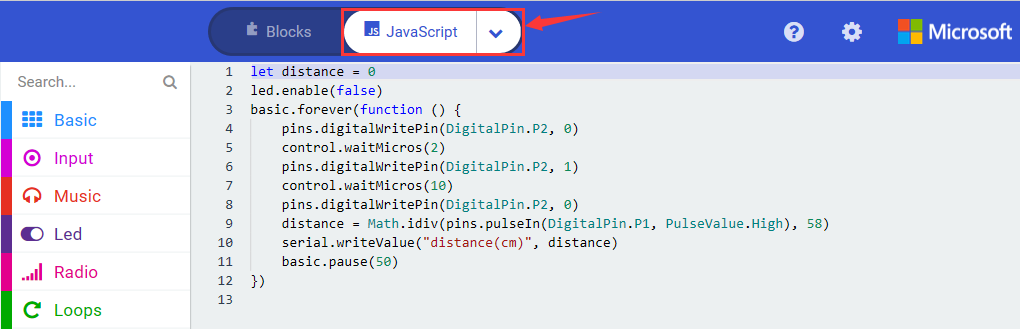

Choose“High E”and set to “1 beat”.